Gasket polishing equipment for hardware tool machining

A hardware tool and gasket technology, which is applied in the field of gasket polishing equipment for hardware tool processing, can solve the problems of manpower consumption, cumbersome operation process, and low work efficiency, and achieve the effects of improving work efficiency, simple operation, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

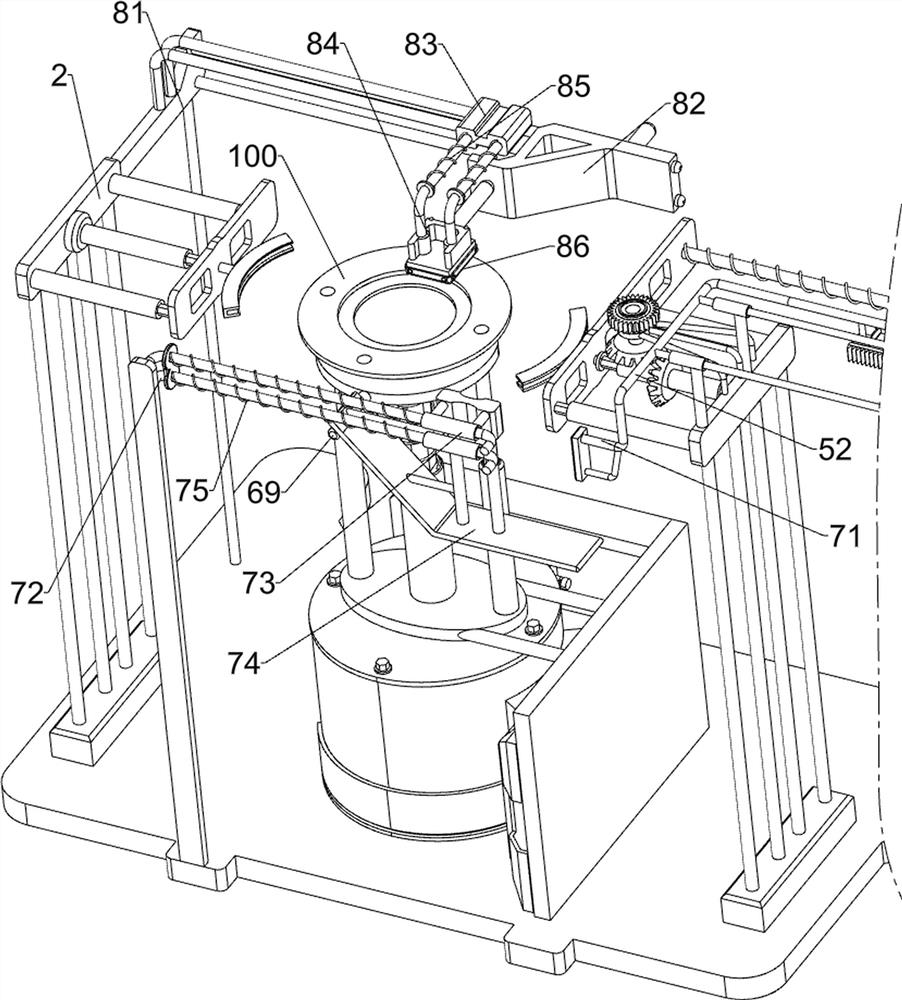

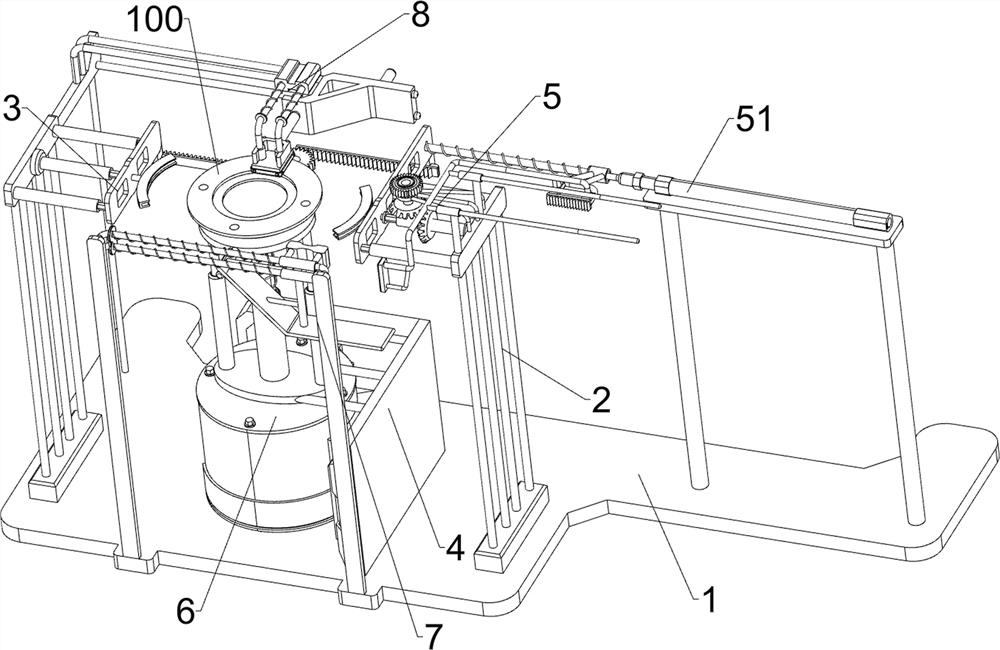

[0024] A pad polishing equipment for hardware tool processing, such as Figure 1-3 As shown, it includes a base 1, a mounting frame 2, a slide plate 3 and a first fixing frame 4. The mounting frame 2 is connected to the left and right sides of the top of the base 1, and the sliding plate 3 is slidably connected to the mounting frame 2, and the two sides are installed The top of the base 1 between the frames 2 is connected with a first fixed frame 4, and also includes a transposition assembly 5 and a rotation assembly 6. A transposition assembly 5 is provided between the mounting frame 2, the base 1 and the slide plate 3, and the first A rotating assembly 6 is provided between the fixed frame 4 , the base 1 and the sliding plate 3 .

[0025] The transposition assembly 5 includes a cylinder 51, a first sliding frame 52, a first compression spring 53, a driving rack 54, an inner diamond sleeve 55, a clamping ring 56, a rotating shaft 57, a bevel gear 58 and a one-way gear 59, bas...

Embodiment 2

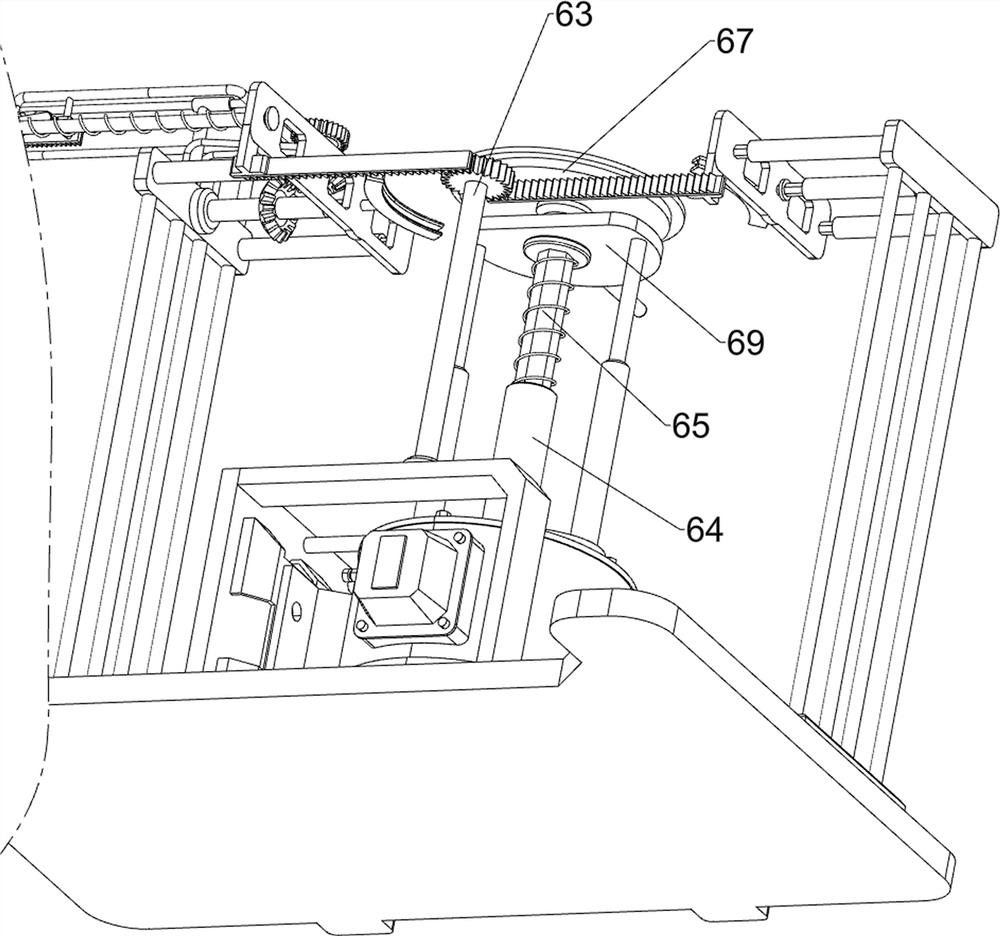

[0029] On the basis of Example 1, such as Figure 4 As shown, the pressing assembly 7 is also included, and the pressing assembly 7 includes a connecting frame 71, a guide rail 72, a second sliding frame 73, an extrusion plate 74 and an elastic member 75, and the connecting frame 71 is connected to the first sliding frame 52. A guide rail 72 is connected to the front side of the top of the base 1, and a second sliding frame 73 is slidably connected to the guide rail 72. An elastic member 75 is connected between the second sliding frame 73 and the guide rail 72. The second sliding frame 73 and the connecting frame 71 In cooperation, the bottom of the second sliding frame 73 is connected with an extruding plate 74, and the extruding plate 74 cooperates with the elevating frame 69.

[0030]When the first sliding frame 52 moves to the left, it drives the connecting frame 71 to move to the left. When the connecting frame 71 moves to the left to contact with the second sliding frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com