Powder grinding device for montmorillonite production

A technology of montmorillonite powder and montmorillonite, which is applied in the field of milling equipment for montmorillonite production, can solve the problems of inability to pre-treat montmorillonite blocks, low milling efficiency, and easily damaged milling equipment, and achieve faster milling High powder efficiency, convenient grinding, and guaranteed utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

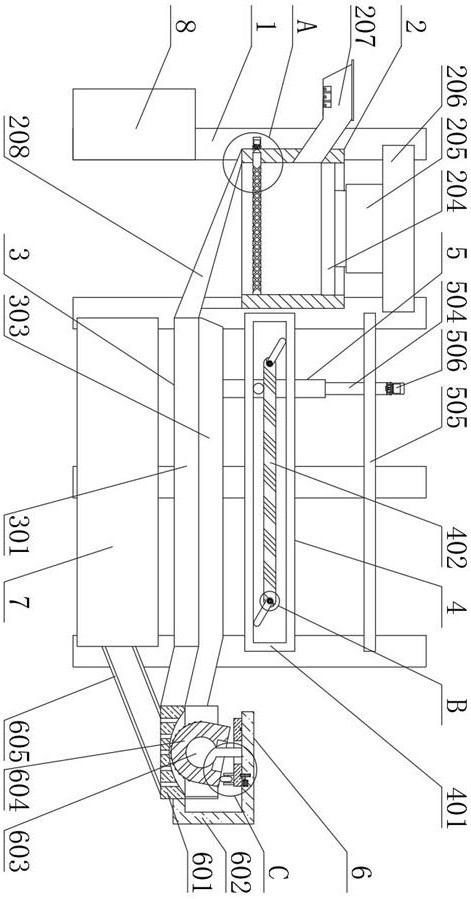

[0025] see Figure 1-6 , the present invention provides a technical solution:

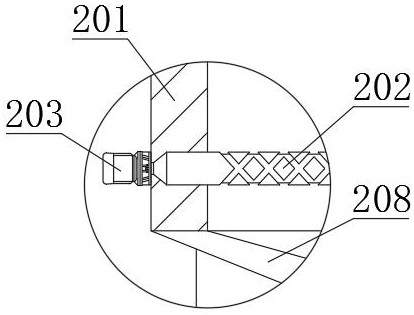

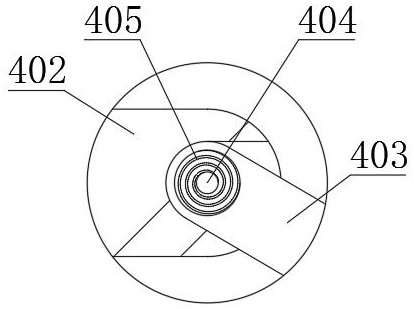

[0026] A milling device for montmorillonite production, comprising a fixed frame 1, a pretreatment crushing mechanism 2, a screening mechanism 3 and a grinding mechanism 6, the pretreatment crushing mechanism 2 is fixedly connected to the left end of the screening mechanism 3, and the fixed frame 1 It is fixedly connected to the front and rear sides of the pretreatment crushing mechanism 2 and the screening mechanism 3. This arrangement supports the pretreatment crushing mechanism 2 and the screening mechanism 3 through the fixed frame 1. The pretreatment crushing mechanism 2 includes a crushing box 201, breaking bar 202, pressing plate 204, top fixed plate 206 and discharge slope 208, discharge slope 208 is fixedly connected with the left end of screening mechanism 3, and screening mechanism 3 comprises fixed plate 301, screen cloth 302 and side plate 303, The bottom of the screening mechanism 3 ...

Embodiment 2

[0030] see Figure 1-6 , the present invention provides a technical solution:

[0031] A milling device for montmorillonite production, the same parts in embodiment 2 as in embodiment 1 will not be repeated in the present invention, and the difference lies in the working process.

[0032] Work flow: the present invention is powered by an external power supply before use, and is controlled by the controller 8. When the montmorillonite to be ground is too large or its surface is relatively smooth, put the montmorillonite from the stone feeding bucket 207 In, the montmorillonite block enters into the pretreatment crushing mechanism 2, and at this time, the crushing motor 203 is started, so that the crushing motor 203 drives the crushing rod 202 to rotate, and the crushing rod 202 will cause montmorillonite after rotation. The block rotates at the top of the crushing rod 202, and now the hydraulic rod 205 can be started, so that the hydraulic rod 205 drives the pressing plate 204...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com