Supercritical particle preparation process of grease

A preparation process and supercritical technology, which is applied in the direction of liquid separation into beads and granulation, can solve the problems of low surface oil rate, achieve high embedding rate, less wall material consumption, and solve the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

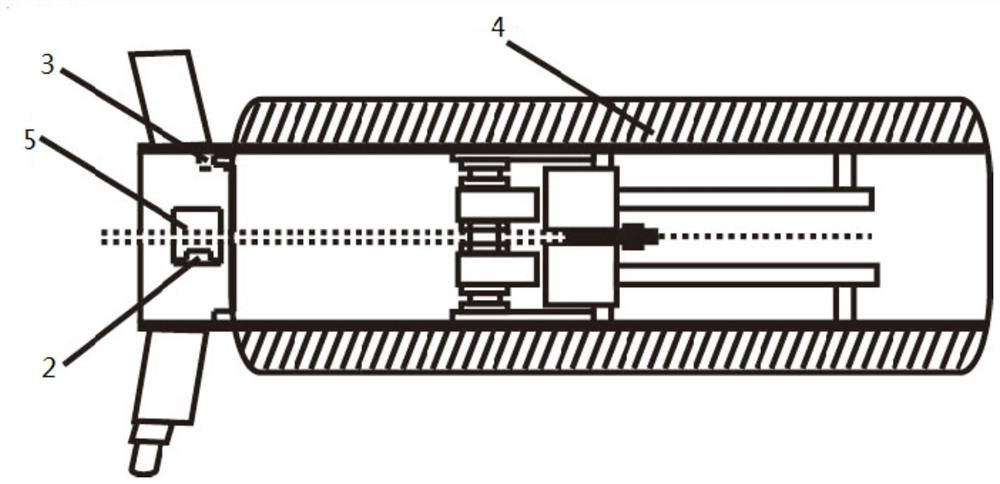

Image

Examples

Embodiment 1

[0035] Mix 10 g of gum arabic and 3 g of sodium alginate and infuse with CO 2 In the fluid reaction kettle, add Tween 80 and linseed oil, and cover it. Open CO 2 The cylinder is pressurized by a high-pressure pump and enters the fluid reactor. 50mL of purified water in the storage tank was injected into the reaction kettle at a speed of 5mL / min. Adjust the pre-expansion pressure to 5MPa, the pre-expansion temperature to 38K, and the magnetic stirring power to 20MPa, and stir for 30 minutes until the microemulsion is fully formed. Then set the pressure of the collection tank to be 5MPa, the temperature to be 298K, and control the supercritical CO 2 Precipitation conditions, rapid release of pressure, the formed microemulsion with CO 2 Spray into the collection tank through the nozzle at a flow rate of 2L / min, so that the grease particles are evenly dispersed in the water phase medium. After the injection process is over, keep the pressure and continue to feed CO into the c...

Embodiment 2

[0037] Mix 10 g of gum arabic and 3 g of sodium alginate and infuse with CO 2 In the fluid reaction kettle, add Tween 80 and linseed oil, and cover it. Open CO 2 The cylinder is pressurized by a high-pressure pump and enters the fluid reactor. 50mL of purified water in the storage tank was injected into the reaction kettle at a speed of 5mL / min. Adjust the pre-expansion pressure to 10MPa, the pre-expansion temperature to 38K, and the magnetic stirring power to 20MPa, and stir for 30 minutes until the microemulsion is fully formed. Then set the pressure of the collection tank to be 5MPa, the temperature to be 298K, and control the supercritical CO 2 Precipitation conditions, rapid release of pressure, the formed microemulsion with CO 2 Spray into the collection tank through the nozzle at a flow rate of 2L / min, so that the grease particles are evenly dispersed in the water phase medium. After the injection process is over, keep the pressure and continue to feed CO into the ...

Embodiment 3

[0039] Mix 10 g of gum arabic and 3 g of sodium alginate and infuse with CO 2 In the fluid reaction kettle, add Tween 80 and linseed oil, and cover it. Open CO 2 The cylinder is pressurized by a high-pressure pump and enters the fluid reactor. 50mL of purified water in the storage tank was injected into the reaction kettle at a speed of 5mL / min. Adjust the pre-expansion pressure to 15MPa, the pre-expansion temperature to 38K, and the magnetic stirring power to 20MPa, and stir for 30 minutes until the microemulsion is fully formed. Then set the pressure of the collection tank to be 5MPa, the temperature to be 298K, and control the supercritical CO 2 Precipitation conditions, rapid release of pressure, the formed microemulsion with CO 2 Spray into the collection tank through the nozzle at a flow rate of 2L / min, so that the grease particles are evenly dispersed in the water phase medium. After the injection process is over, keep the pressure and continue to feed CO into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com