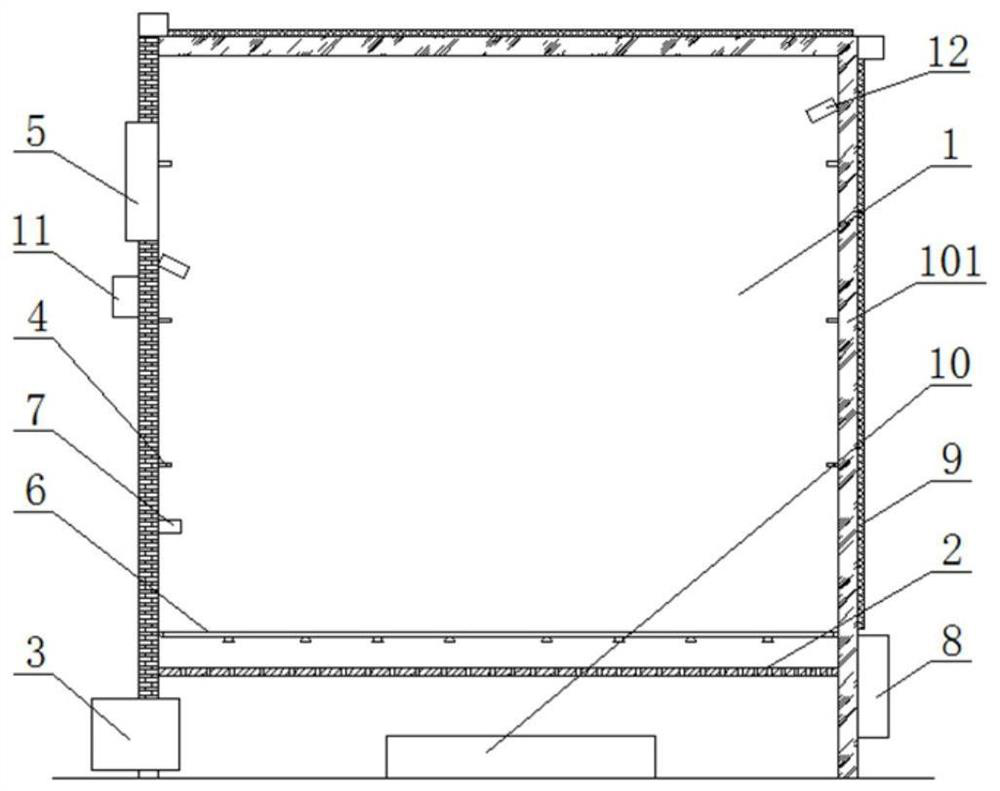

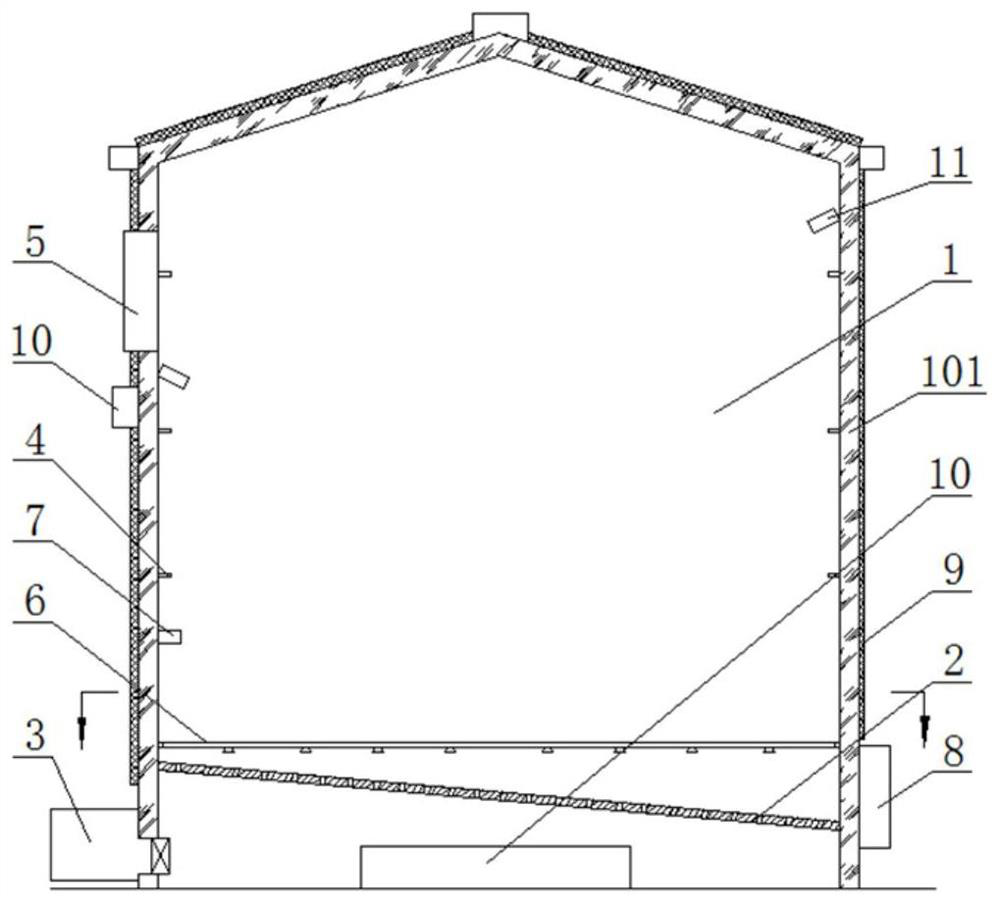

Vitrification sun-curing room for heating cigarette tobacco leaf raw materials for modulation and modulation method

A modulation method and vitrification technology, applied in application, tobacco, preparation of tobacco, etc., can solve the problems of insufficient aroma, deteriorating quality of sun-cured tobacco, rough smoke, etc., to improve the degree of intelligence, improve the quality of drying, The effect of shortening the modulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

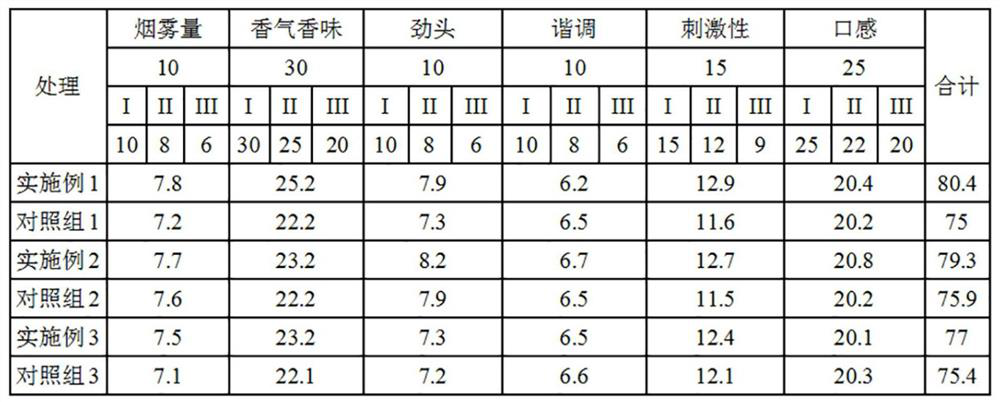

Embodiment 1

[0046] S100: Harvest flue-cured tobacco KRK26 tobacco leaves with white tendons, light yellow leaves and most of the down hairs in Midu County, Dali Bai Autonomous Prefecture, Yunnan Province, string them at a density of 450 pieces / m, and then pack them into vitrification In the drying room, the distance between the tobacco strings behind the drying chamber is 12cm, the distance between the tobacco leaf layers is 0.6m, and the distance between the bottom of the bottom tobacco leaf and the heat insulation board is 1.2m. on the cigarette holder.

[0047] S200: Control the temperature in the drying room at 22°C and the relative humidity at 65%, and dry for 3 days at a stable temperature and humidity until the tobacco leaves wither and 70% of the leaf surface turns yellow.

[0048] S300: After withering and turning yellow, adjust the temperature in the drying room to 25°C and adjust the relative humidity to 40%, keep the temperature and humidity stable and continue to dry for 3 da...

Embodiment 2

[0051] S100: Harvest flue-cured tobacco KRK26 tobacco leaves with white tendons, light yellow leaves and most of the down hairs in Midu County, Dali Bai Autonomous Prefecture, Yunnan Province, string them at a density of 480 pieces / m, and then pack them into vitrification In the drying room of the drying room, the distance between the tobacco strings after being put on the shelf is 15cm, the distance between the tobacco leaf layers is 0.8m, and the distance between the bottom of the bottom tobacco leaf and the heat insulation board is 1.2m. on the clamping smoke device.

[0052] S200: Control the temperature in the drying room at 26°C and the relative humidity at 70%, and dry for 3.5 days at a stable temperature and humidity until the tobacco leaves wither and 72% of the leaf surface turns yellow.

[0053] S300: After withering and turning yellow, adjust the temperature in the drying room to 40°C and adjust the relative humidity to 50%, and continue drying at a stable temperat...

Embodiment 3

[0056] S100: Harvest flue-cured tobacco KRK26 tobacco leaves with white tendons, light yellow leaves and most of the down hairs in Midu County, Dali Bai Autonomous Prefecture, Yunnan Province, string them at a density of 500 pieces / m, and then put them into vitrification In the drying room of the drying room, the distance between the tobacco strings after being put on the shelf is 18cm, the distance between the tobacco leaf layers is 1.0m, and the distance between the bottom of the bottom tobacco leaf and the heat insulation board is 1.2m. on the clamping smoke device.

[0057] S200: Control the temperature in the drying room at 28°C and the relative humidity at 80%, and dry for 4 days at a stable temperature and humidity until the tobacco leaves wither and 75% of the leaf surface turns yellow.

[0058] S300: After withering and turning yellow, adjust the temperature in the drying room to 50°C and the relative humidity to 60%, and continue to dry for 4 days at a stable tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com