Solar cell double-glass assembly and assembling method thereof

A technology of solar cells and double-glass modules, which is applied in the field of solar cells, can solve the problems of reduced service life of solar cell double-glass modules, fire solar cell efficiency, and excessive series resistance, so as to avoid the decline of component efficiency, solve poor welding, and solve The effect of lifespan reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

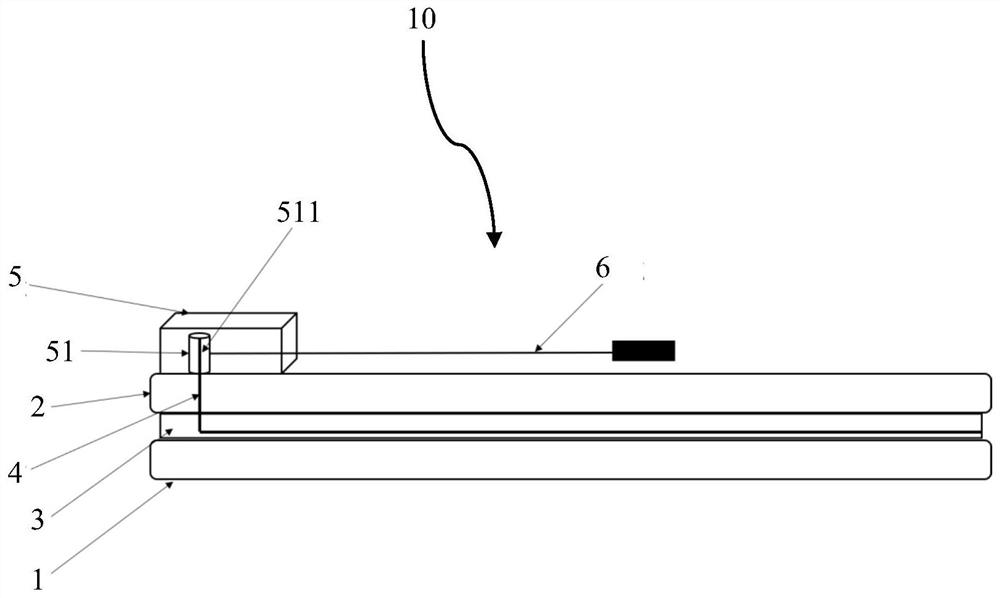

[0036] Such as figure 1 As shown, the solar cell double-glass module 10 of the embodiment of the present invention includes a front glass 1 and a back glass 2 . Wherein, a solar cell 3 is encapsulated between the front glass 1 and the back glass 2 , and the solar cell 3 is located on the back glass 2 . The back glass 2 is provided with a conductive bus bar 4 connected to the solar cell 3 , and the conductive bus bar 4 passes through the back glass 2 and is connected to the junction box 5 . The junction box 5 is provided with a connection terminal 51 connected to the conductive bus bar 4 , and the connection terminal 51 and the conductive bus bar 4 are connected by filling with a curable conductive fluid. The junction box 5 is used for connecting with an external cable 6 .

[0037] According to the solar cell double-glass module of the embodiment of the present invention, the connection terminal is fully connected to the conductive bus bar by filling it with a curable conduct...

Embodiment 2

[0042] Such as figure 1As shown, the method for assembling the solar cell double-glass module 10 according to the embodiment of the present invention includes the following steps: S01, after drilling the back glass 2 provided with the solar cell and laying the conductive bus bar 4, the conductive bus bar 4 It is connected with the solar cell 3 and leads out the backplane glass 2 through the drilled hole. S02 , introducing the conductive bus bar 4 into the groove structure 511 in the connection terminal 51 of the junction box 5 . S03. Fill the groove structure 511 of the connection terminal 51 with a curable conductive fluid. S04, curing the conductive fluid.

[0043] According to the method for assembling solar cell double-glass modules of the embodiment of the present invention, the method of filling the conductive fluid that can be cured is used to fully connect the terminal and the conductive bus bar, and the series resistance is reduced. After the fluid metal is cured, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com