Aerial operation robot for power transmission line maintenance

A technology for operating robots and transmission lines, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as line tripping, impact on line transmission performance, and insufficient efficiency, and achieve the effects of reducing the degree of disturbance, good cutting effect, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

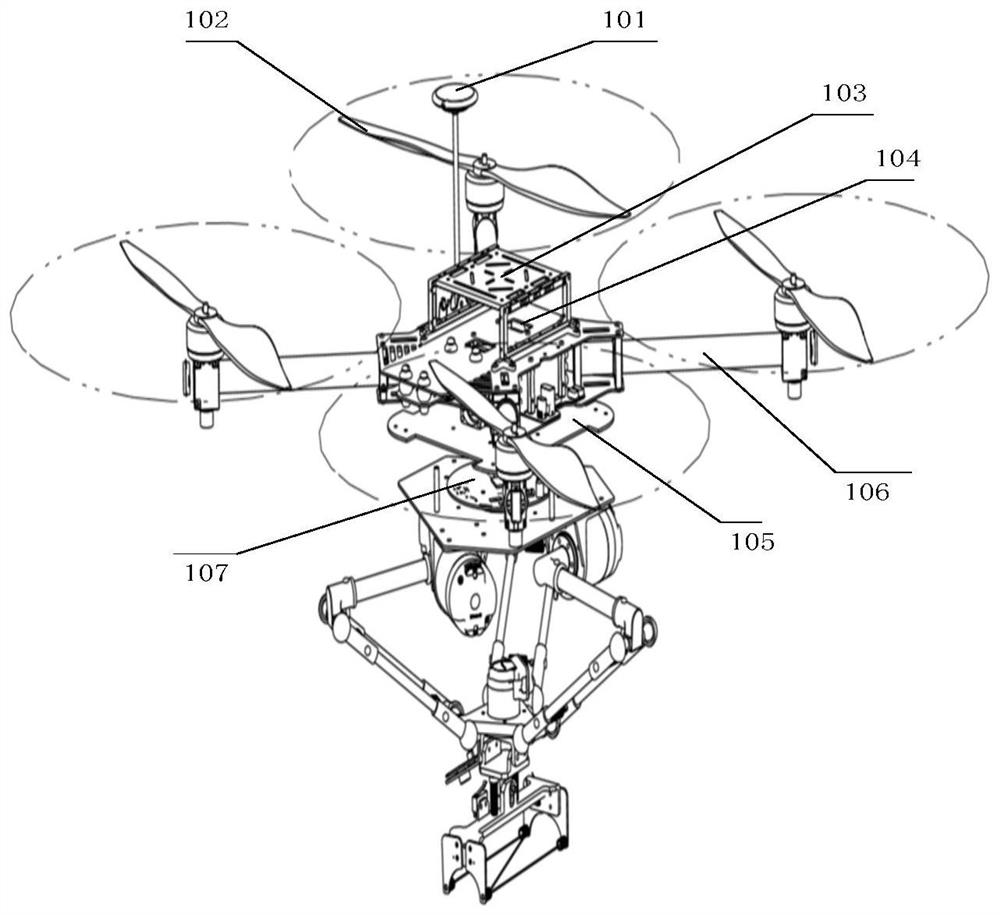

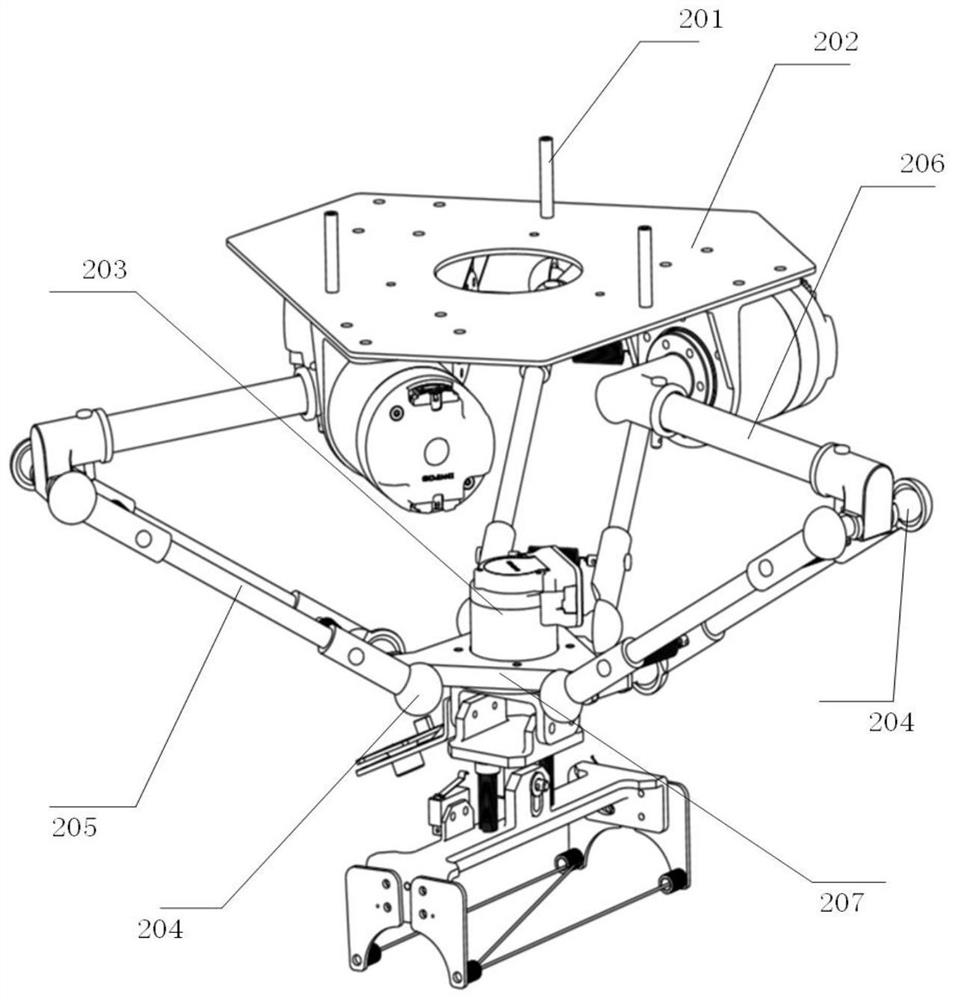

[0034] Such as figure 1 As shown, an aerial robot for power transmission line maintenance provided by Embodiment 1 of the present invention includes a multi-rotor UAV platform that provides flight power for the aerial robot, and a four-degree-of-freedom Delta parallel connection that dynamically compensates for UAV attitude changes. Mechanism, cutting operation mechanism for floating removal.

[0035] In this embodiment, the multi-rotor UAV platform includes four wings 102, a frame 106, a GPS device 101, a flight controller, a power supply module, and an onboard computer module. The wings 102 are installed on the outermost end of the frame 106, and the rotation of the wings 102 can provide lift for the aerial work robot, and the four sets of wings 102 are respectively distributed at 90 degrees.

[0036] The flight controller is the control center of the multi-rotor UAV. It is installed on the carbon fiber mounting plate No. 2, 104, and the onboard computer module is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com