Rotary drawing film blowing production technology

A technology of production process and production equipment, which is applied in the field of rotary traction blown film production process, can solve the problems of easy stretching of the film, irregular edges, and uneven film roll, so as to achieve dense film roll, neat edges at both ends, and The effect of low moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

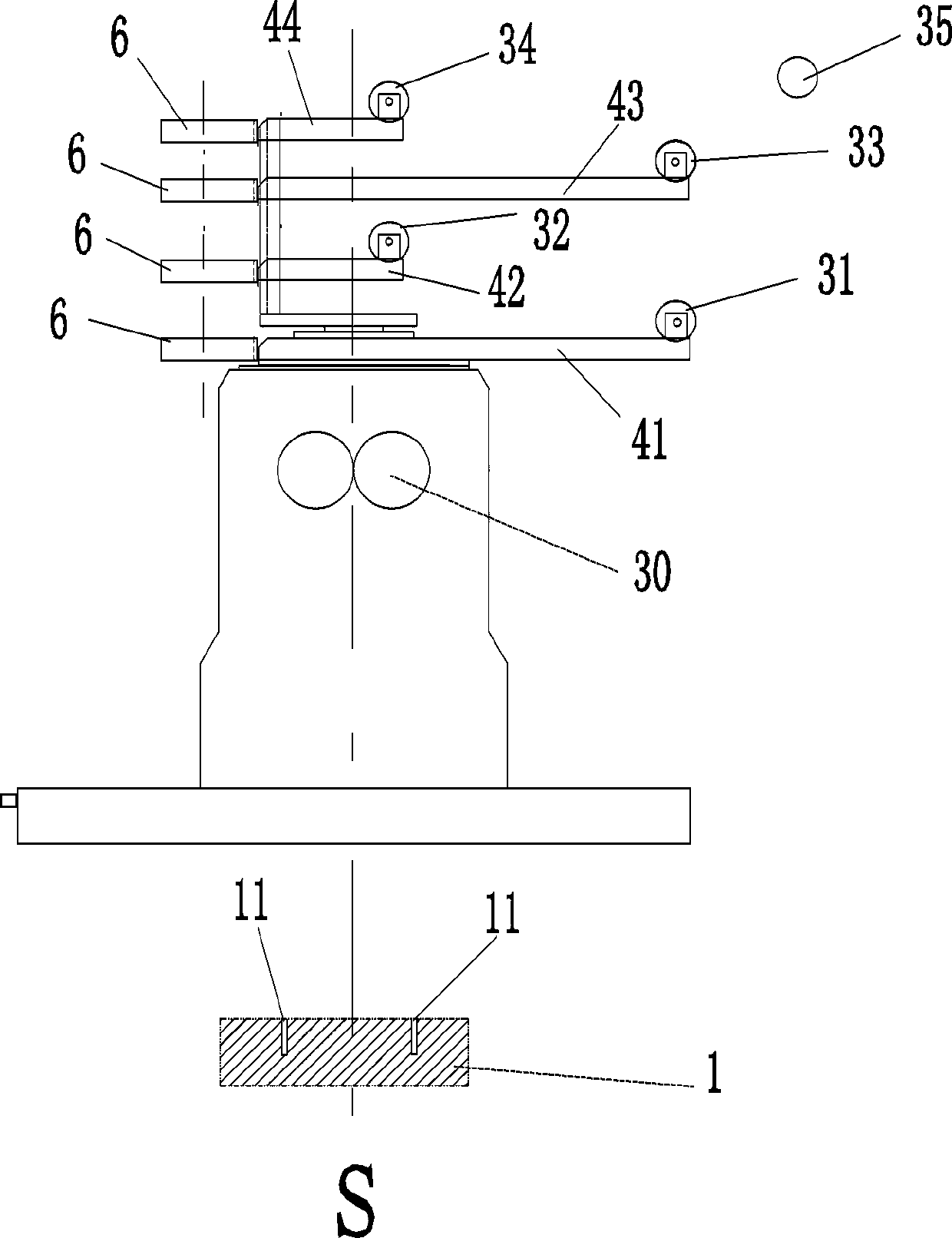

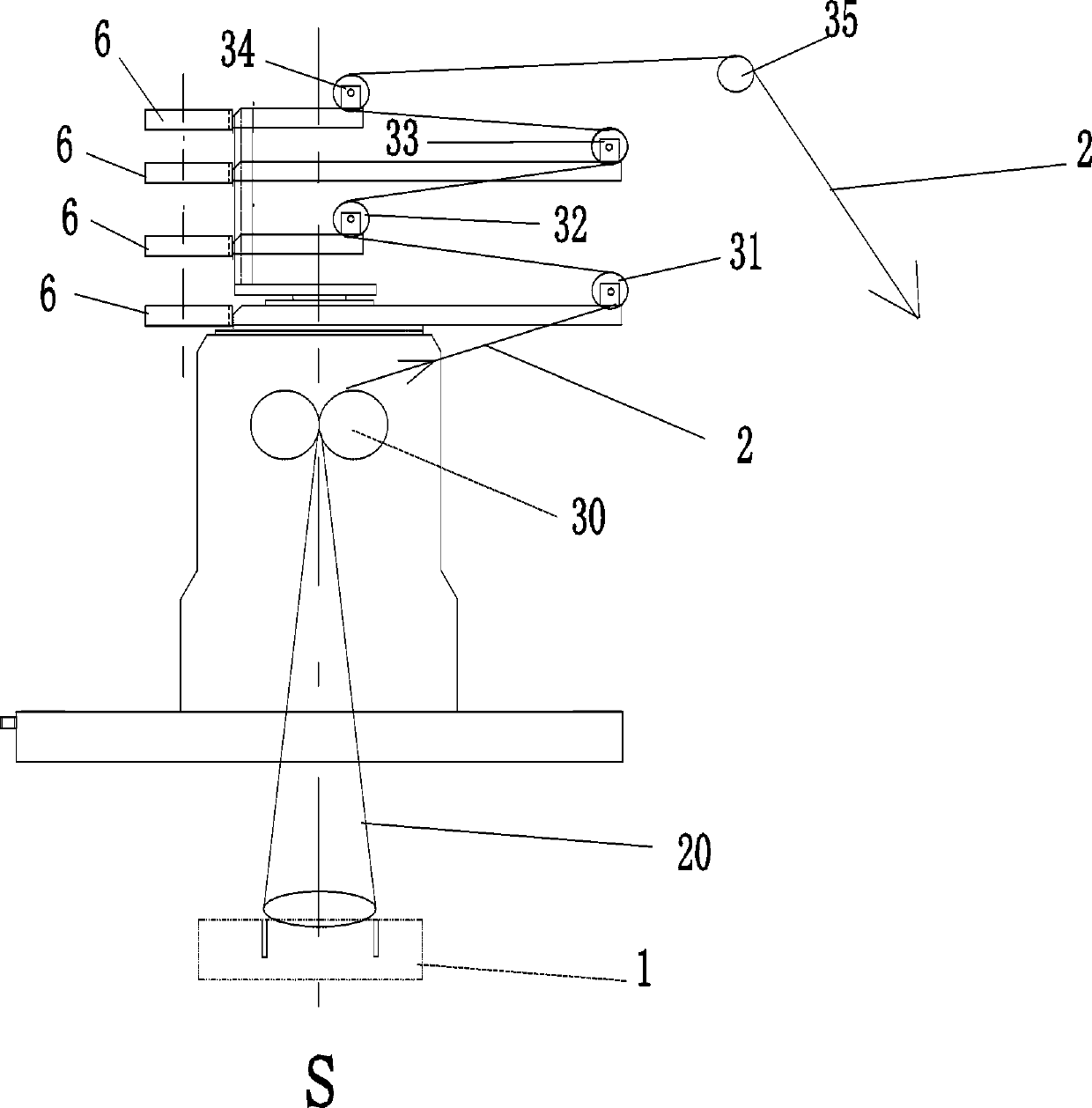

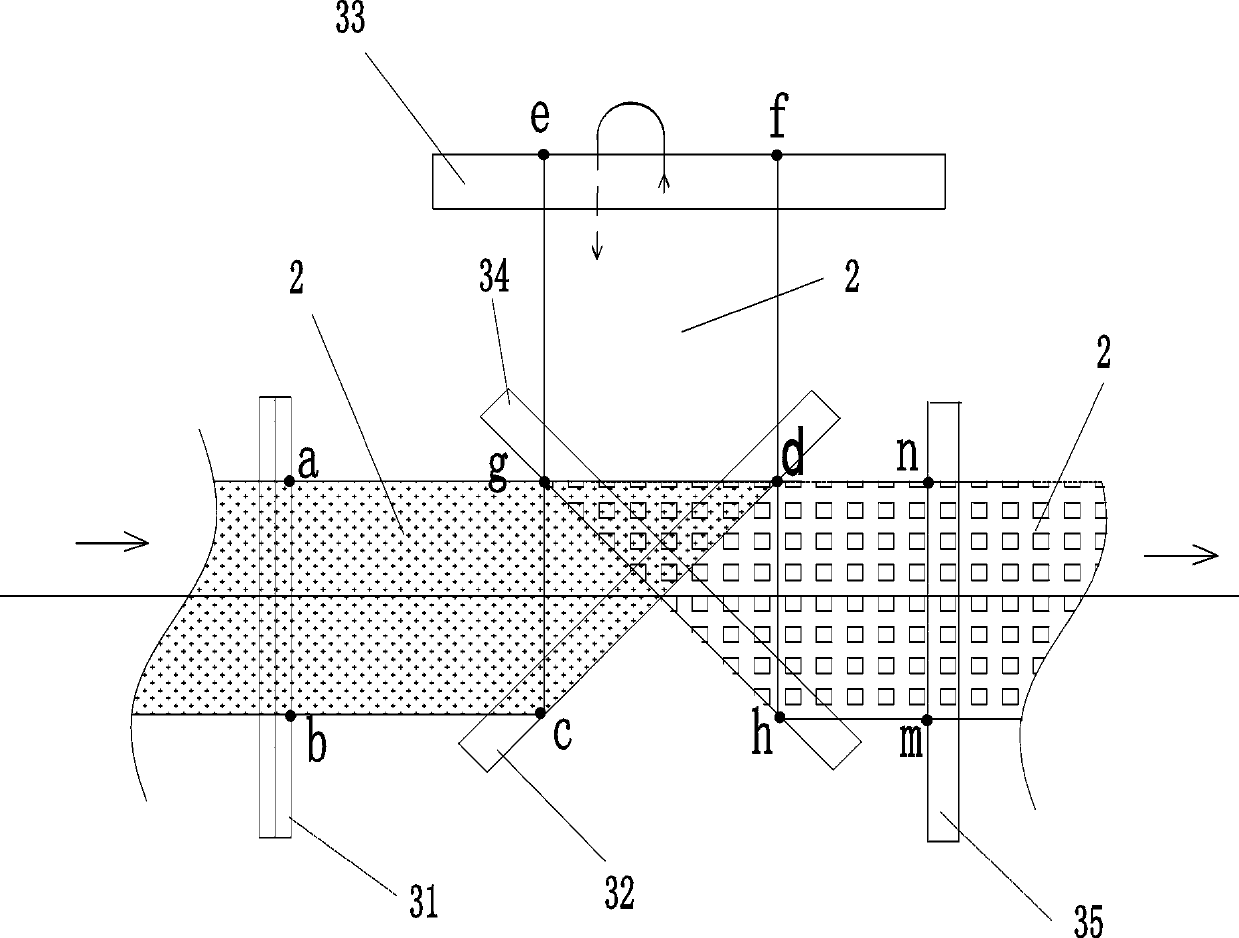

[0029] A rotary traction blown film production process, the rotary traction blown film production equipment adopted is provided with a central controller and an extrusion die head, the extrusion die head is provided with a circular extrusion port 11, and the top of the extrusion die head 11 is sequentially arranged There are traction nip rollers 30, first horizontally movable guide rollers 31, second horizontally movable guide rollers 32, third horizontally movable guide rollers 33, and fourth horizontally movable guide rollers 34, wherein the first horizontally movable guide rollers 31, the third horizontally movable guide rollers The horizontal position of the horizontal movable guide roller 33 is far away from the vertical central axis S of the annular extrusion port 11, while the horizontal positions of the second horizontal movable guide roller 32 and the fourth horizontal movable guide roller 34 are then close to the center of the circular annular extrusion port Axis S, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com