Electrode material with conductive functional zone structure on the surface

A technology of electrode materials and functional areas, applied in the field of reversible battery materials, can solve problems such as insufficient performance improvement, a large number of coated materials, and increased production costs, so as to avoid adverse effects, increase specific capacity, and reduce mass proportion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Lithium-ion battery electrode material 811 (LiNi 0.8 co 0.1 mn 0.1 o 2 ) as a matrix material, the structural design is as follows: construct an incompletely covered electron-conducting functional region on the surface of the substrate, and then construct an ion-conducting functional region that does not completely overlap with it.

[0066] The specific operation steps are:

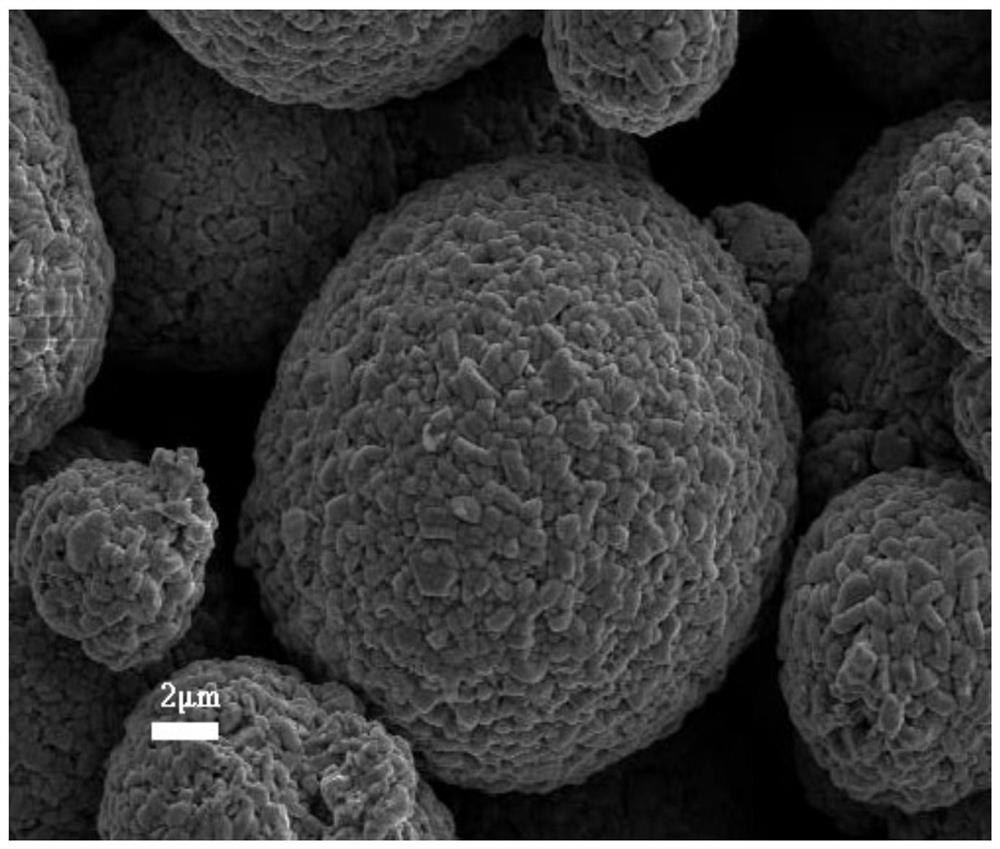

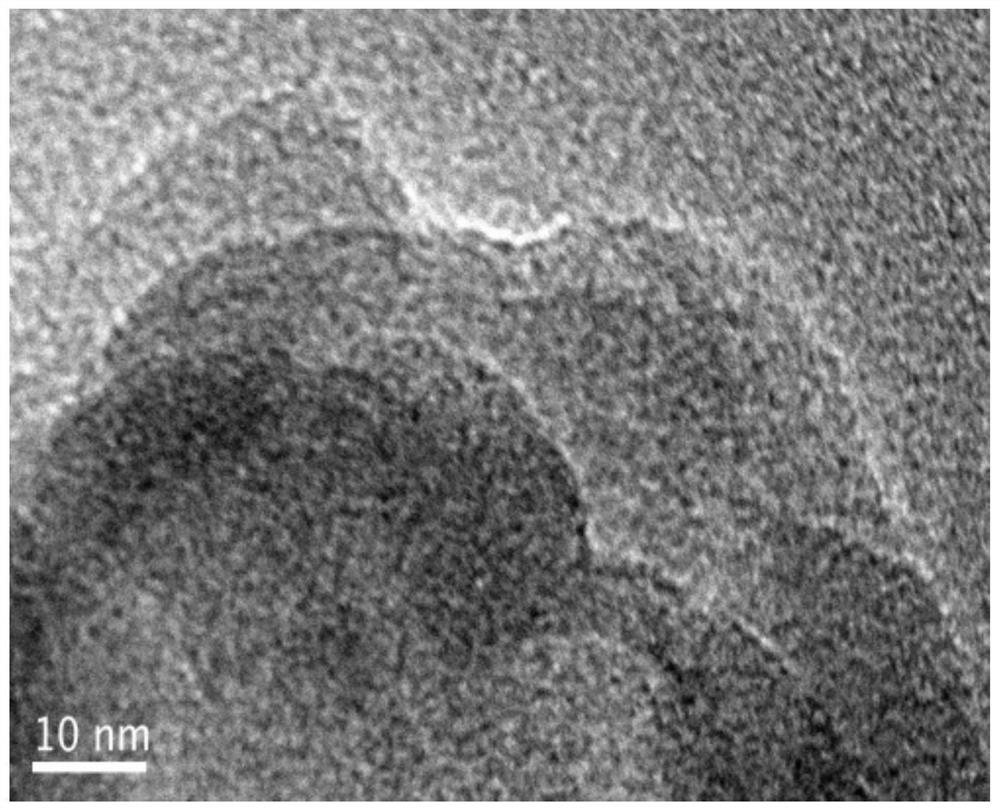

[0067] Take 1g of 811 material (particle size is 5-15μm), mix it evenly with sucrose according to 2% mass ratio, heat in one direction at 3000°C for 0.1s, carbonize the heating surface at high temperature, put it into 100ml room temperature pure water immediately, and ultrasonicate for 10min to remove untreated Carbonized sucrose to obtain a functional area containing conductive carbon on the surface; mechanically mix the obtained material with 0.01g LiSICON fast ion conductor lithium zinc germanate, heat in one direction at 3000°C for 1s, and the lithium zinc germanate on the heating surface an...

Embodiment 2

[0080] Sodium manganese oxide, the electrode material of sodium ion battery, is used as the matrix material, and a corrosion-resistant protective shell is constructed on the surface, and an electronic conductor functional area is constructed on the shell.

[0081] Take 1g of sodium manganese oxide powder, put it into the aluminum chloride solution with a concentration of 5%, add 5% sodium hydroxide dropwise under the condition of stirring, generate aluminum hydroxide and deposit on the surface of the substrate, rinse it with water three times, Sintering at 750°C for 3 hours to obtain an alumina-coated base material. Take 0.02g of nickel oxide and mix it with the above-mentioned materials, irradiate the laser in one direction for 1 second, and the nickel oxide is thermally decomposed into metallic nickel, and then ultrasonically treated in the same manner as in Example 1, and the unreacted nickel oxide is removed, thus obtaining a protective shell Material on which the ribbon i...

Embodiment 3

[0084] Manganese magnesium oxide (MgMn 2 o 4 ) as the matrix material, the electronic conductor metal zinc incomplete coating area is firstly constructed, and then the electronic conductor metal aluminum area that is incompletely overlapped with it is constructed.

[0085] Take 1g of manganese and magnesium oxide, mix it with metal zinc powder according to 1.5% mass ratio, and heat it in one direction at 3000°C for 1s under the protection of nitrogen, and deposit the zinc powder in the heated area. The same method as in Example 1 is used to remove unheated zinc; The material is mixed with 0.02g of metallic aluminum powder, irradiated with a unidirectional laser for 1s under the protection of nitrogen, and treated in the same way as above to obtain conductive functional areas in different regions.

[0086] The above-mentioned materials were used to prepare positive electrodes and assemble magnesium-ion batteries. The properties obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com