Cable core shaping device

A technology of shaping device and fixing device, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of messy arrangement of wire cores, misalignment and offset between wire cores, and shape deformation of cable outer sleeves, etc., to achieve The effect of improving structural strength and avoiding offset displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

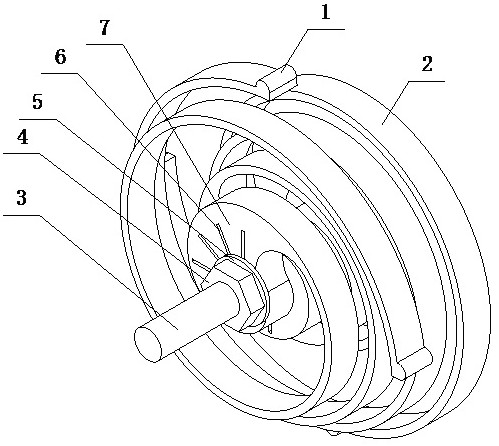

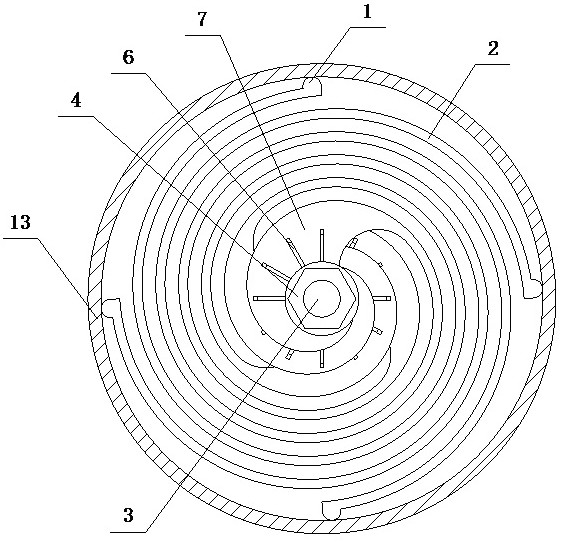

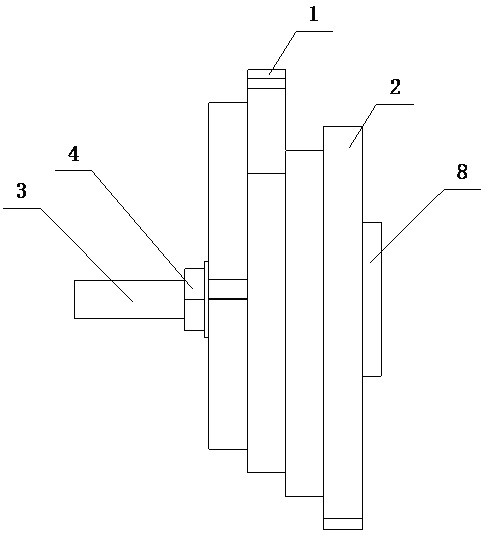

[0018] The cable core shaping device of the present invention is realized in this way: the cable core shaping device of the present invention is composed of a main body supporting device and a fixing device, and the main body supporting device is composed of a centering column (3), a fixing nut (4), a protective pad ( 5), the limit block (8) and the fixed slot (9), the centering column (3) and the middle of the limit block (8) are connected, the limit block (8) is a circular block, the There is a fixed slot (9) radially on the limit block (8), the protective pad (5) is placed on the centering column (3), the fixing nut and the centering column (3) are screwed together, and the fixing device It consists of anti-slip convex pad (1), swirl plate (2), angle slot (6), center solid plate (7), perforation (10), insert block (11) and threading slot (12), swirl plate (2) One end is connected to the central solid plate (7), the other end of the vortex plate (2) vortex extends away from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com