Rapid and automatic mica plate splitting and feeding jig

A mica sheet and jig technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of improper spacing of mica sheets, blocking of feeding materials, and inability to apply the structural characteristics of mica sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

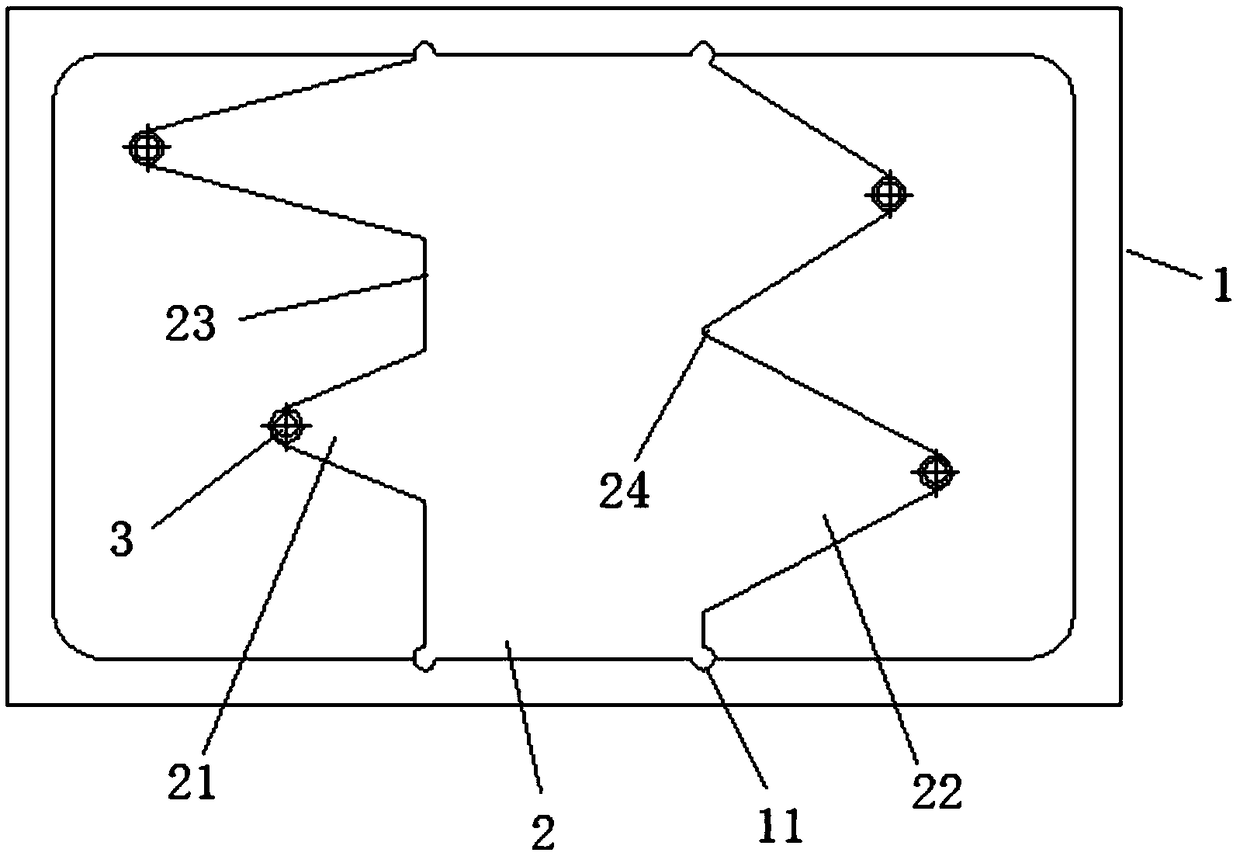

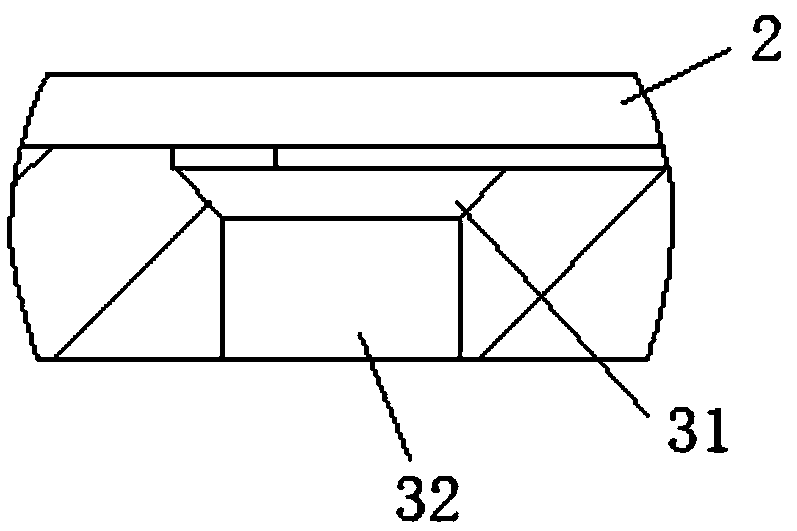

[0021] refer to Figure 1-2 As shown, this embodiment is a fast and automatic feeding jig for mica sheets, including a board body jig 1, a groove 2 arranged in the board body jig 1, and a number of blanking holes 3 arranged in the groove 2 .

[0022] The board jig 1 is a rectangular board body, and the surface of the board jig 1 is smoothed and has a galvanized surface layer.

[0023] The groove 2 includes a plurality of first acute angle grooves 21 protruding outward on one side of the board jig 1 and a plurality of second acute angle grooves 22 protruding outward on the other side of the board jig 1 .

[0024] In this embodiment, there are two first acute-angle grooves 21 and two second acute-angle grooves 22 .

[0025] A connection portion 23 parallel to the side of the board jig is provided between the plurality of first acute angle grooves 21 .

[0026] An acute angle portion 24 is provided between the plurality of second acute angle grooves 22 and extends oppositely t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com