Inner hexahedron anti-cracking manufacturing method based on punching process

A manufacturing method and hexahedral technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as dangerous failures and property loss, metal damage, aggravated hydrogen embrittlement cracking effect, etc., to eliminate stress corrosion, reduce Cutting force, the effect of reducing the amount of back-engagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

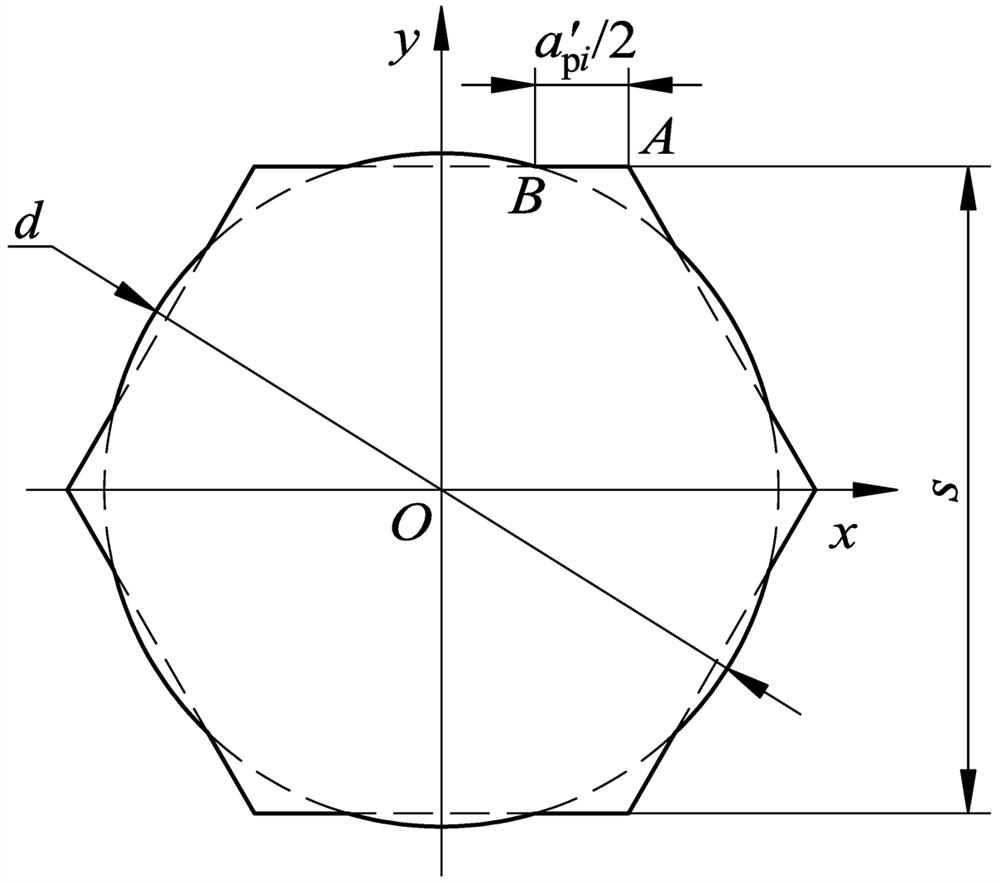

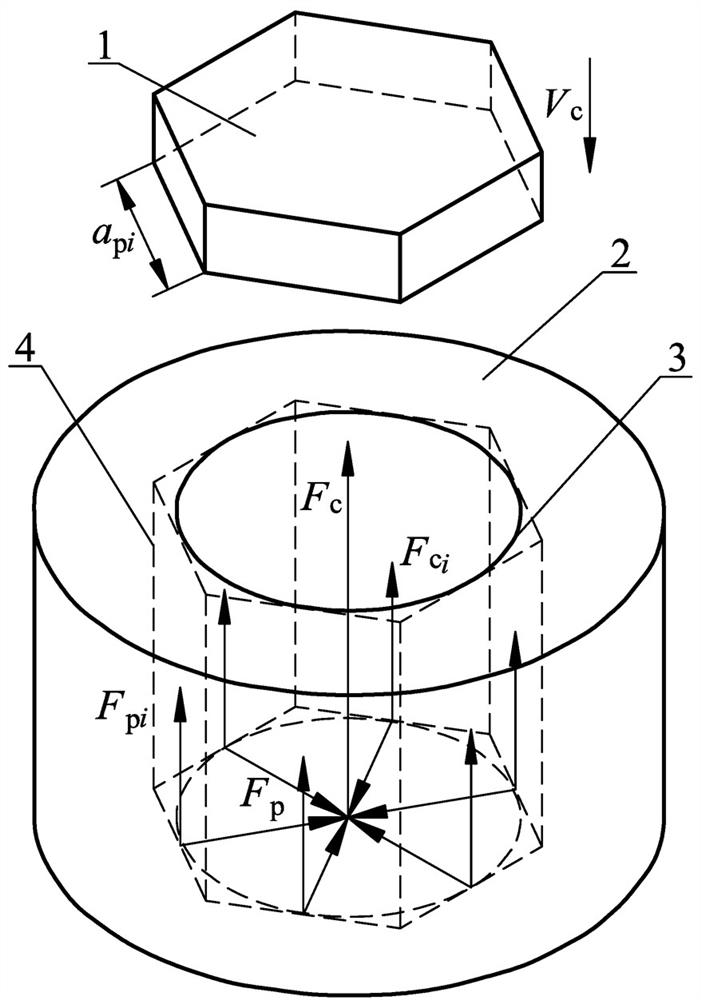

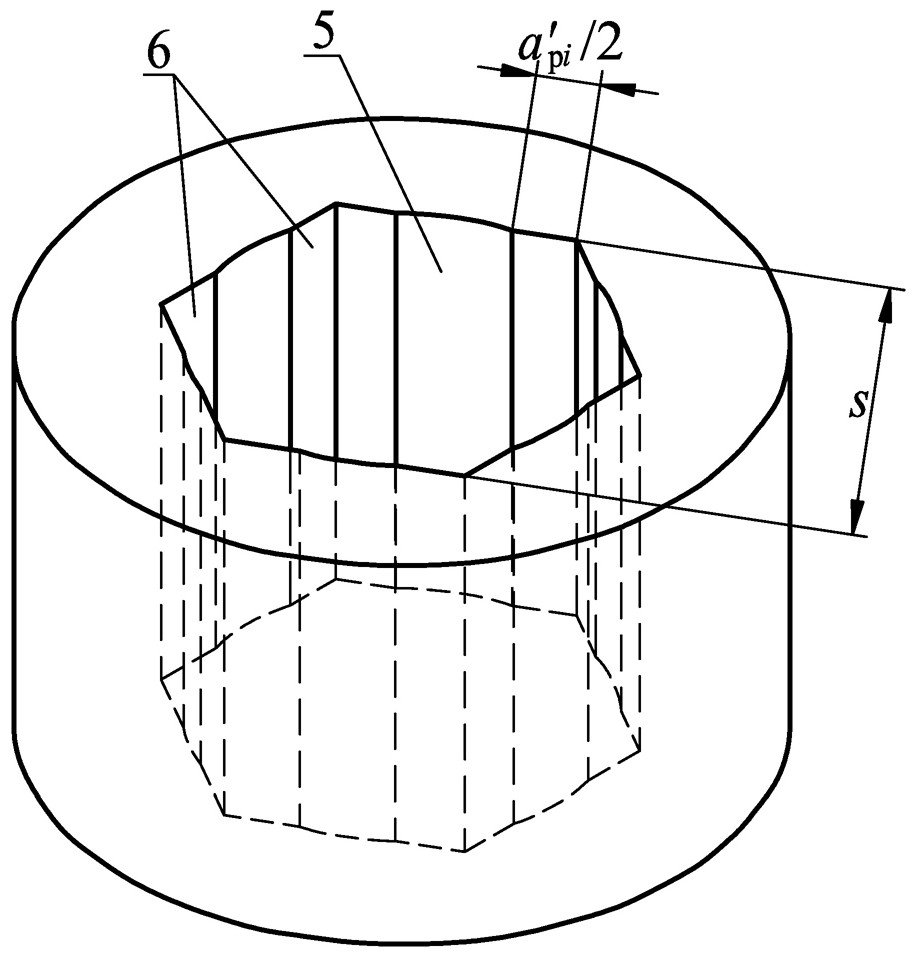

[0048] like Figure 1 ~ Figure 3As shown in the figure, the inner hexahedron anti-cracking manufacturing method based on the punching process includes processing a prefabricated bottom hole 3 on the base body 2, and the rotation centerline of the punch 1 coincides with the rotation centerline of the prefabricated bottom hole 3. Driven by the power device Next, after punching the base body 2, the punch 1 forms an inner hexahedron 4, which is characterized in that the diameter of the prefabricated bottom hole 3 is greater than the size s of the opposite side of the inner hexahedron, and the specific steps are as follows:

[0049] 1. Increase the diameter of the prefabricated bottom 3 during machining before punching, so that the diameter of the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com