Installation method of fresh air handling unit

An installation method and technology for fresh air units, which are applied in heating methods, ventilation systems, space heating and ventilation, etc., can solve the problem of loose mounting holes and bolts, affecting the heat dissipation effect of the fresh air unit, and affecting the installation stability and firmness of the fresh air unit. and other problems to achieve the effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

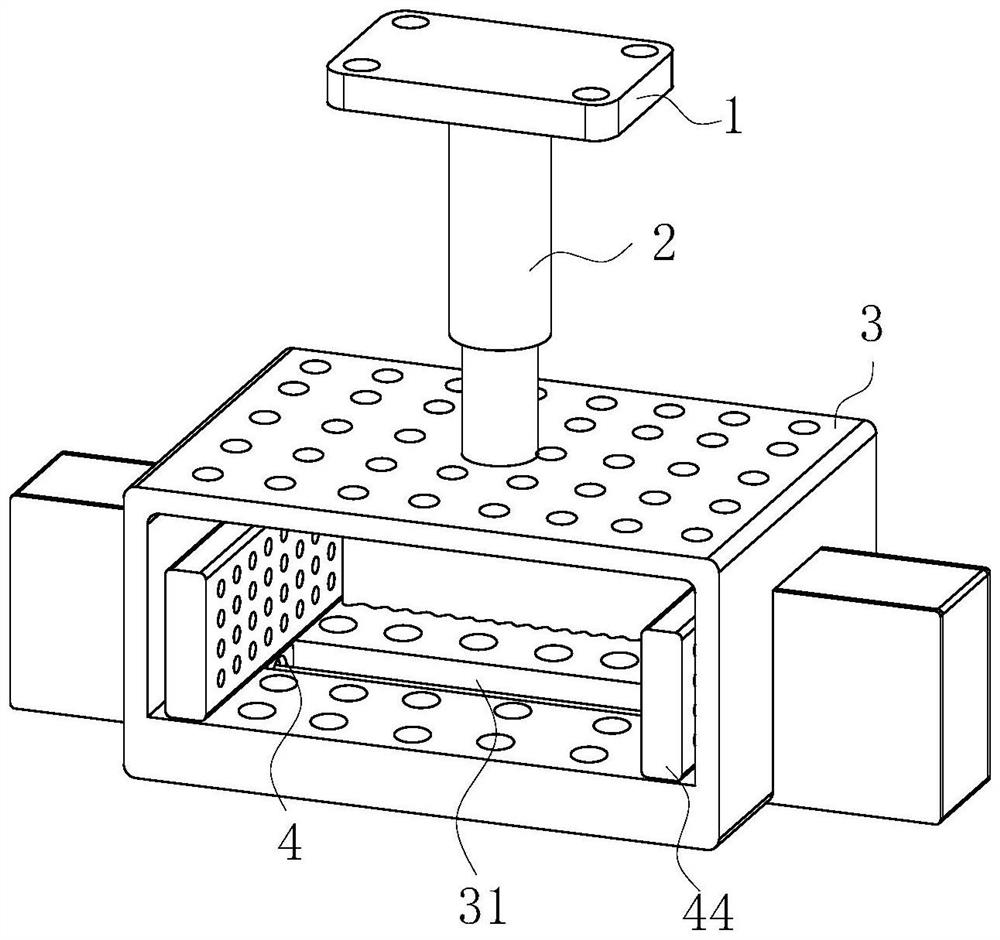

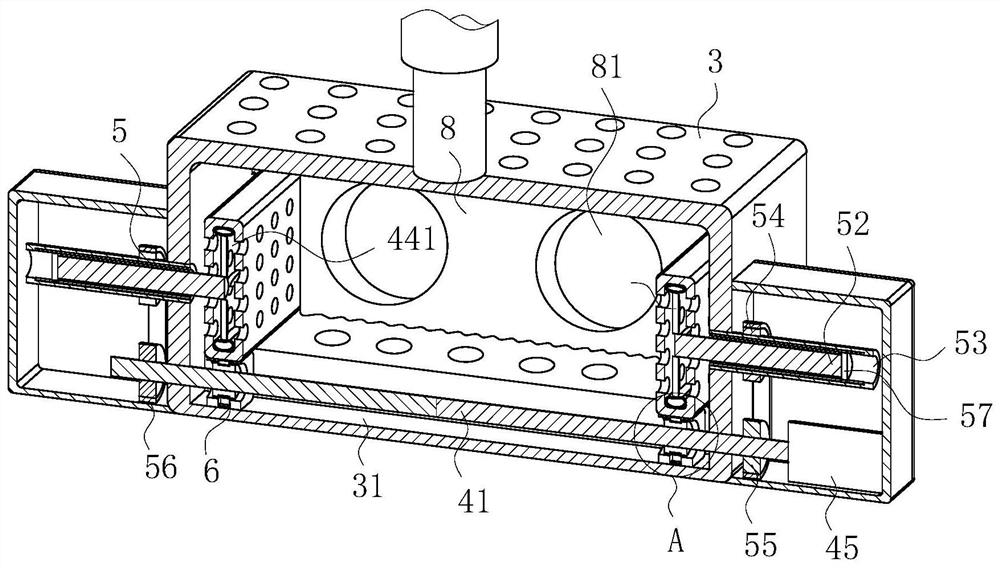

[0034] As an embodiment of the present invention, the mobile clamping mechanism 4 includes a bidirectional screw screw 41, a screw sliding sleeve 42, a sliding seat 43, a clamping net plate 44 and a drive motor 45; the bidirectional screw screw 41 Rotate and insert into the guide chute 31, and the two-way helical screw 41 is symmetrically sleeved with the screw sliding sleeve 42; the top end of the sliding seat 43 is fixed on the clamping net plate 44, and the bottom end of the sliding seat 43 slides Touch the bottom end of the guide chute 31; the sliding seat 43 is provided with a rotating cavity 431, and a screw sliding sleeve 42 is inserted in the rotating cavity 431; the screw sliding sleeve 42 is clamped by the grinding assembly 6 and Sliding seat 43 is connected;

[0035] During work, the direction of rotation of the helix on the bidirectional helical screw 41 is set symmetrically opposite to the two ends along the center of the bidirectional helical screw 41; 45 rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com