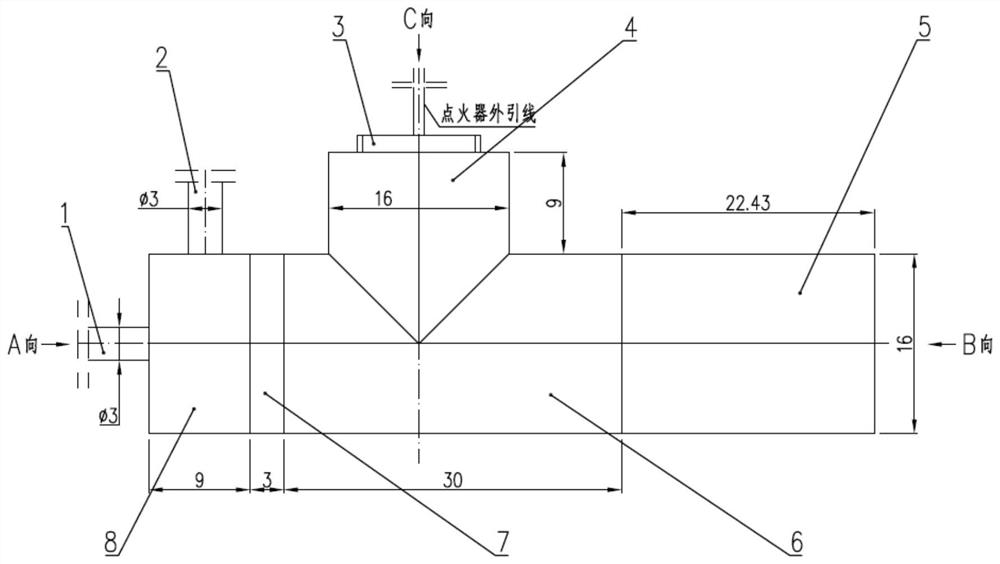

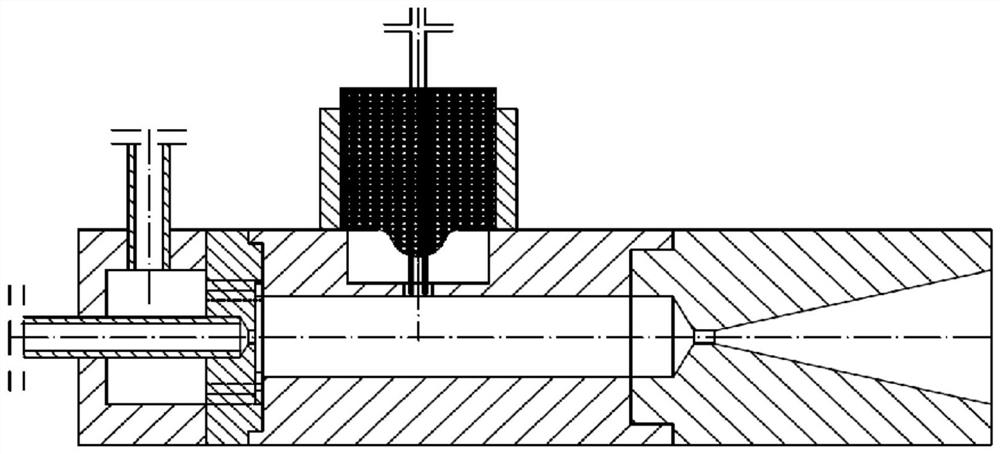

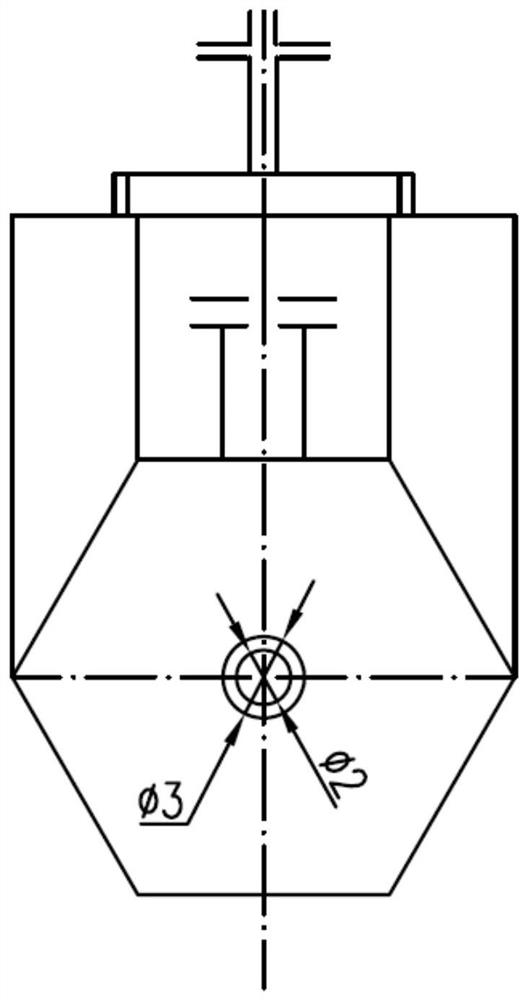

A structure of a swirling micro gas hydrogen oxygen thruster

A swirl type thruster technology, which is applied in the field of swirl type miniature gas hydrogen oxygen thruster structure, can solve the problems of low output power of the thruster and small flow rate of oxygen combustion, so as to improve the work adaptability and enhance the mixing of oxygen combustion , The effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] When the thrust is operated, hydrogen is inserted from the axial direction of the burnout from the end; the oxygen is injected from the end wall surface, forming an initial turning flow field in the combustion chamber. Hydrogen is mixed in the vicinity of the outlet of the bubble injection, starts to burn after ignition, and form a high temperature zone in the center. The high-temperature product airflow generated by the combustion is ejected via the nozzle, producing thrust.

[0039] The technical characteristics of the present invention are as follows:

[0040] 1) Rapid mixture

[0041] By adjusting the fusion speed ratio of the oxidant, a vortex field of different swirl numbers can be formed. When the number of quasi-whettone rings is in 0.6 to 1.2, the Vortex Breakdown has occurred, and the central negative pressure region is formed. Axial Reverse Pressure-gradient drives fresh oxygen in the downstream to the upstream center area, mixing with fresh hydrogen, greatly inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com