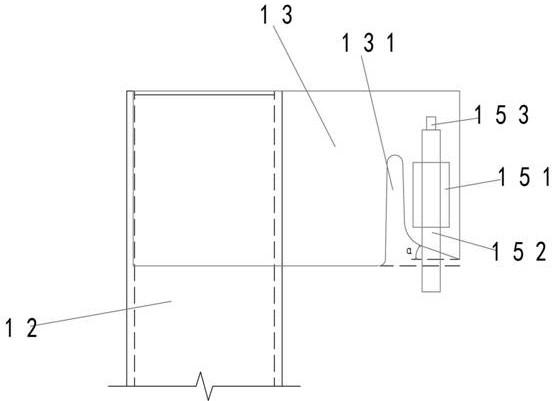

Plug-in light steel exterior wall panel connection node

A technology for hanging wall panels and connecting nodes, applied in the direction of walls, building components, buildings, etc., can solve the problems of high labor cost, long construction period, low efficiency, etc., and achieve high installation efficiency, controllable installation accuracy, and node bearing capacity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

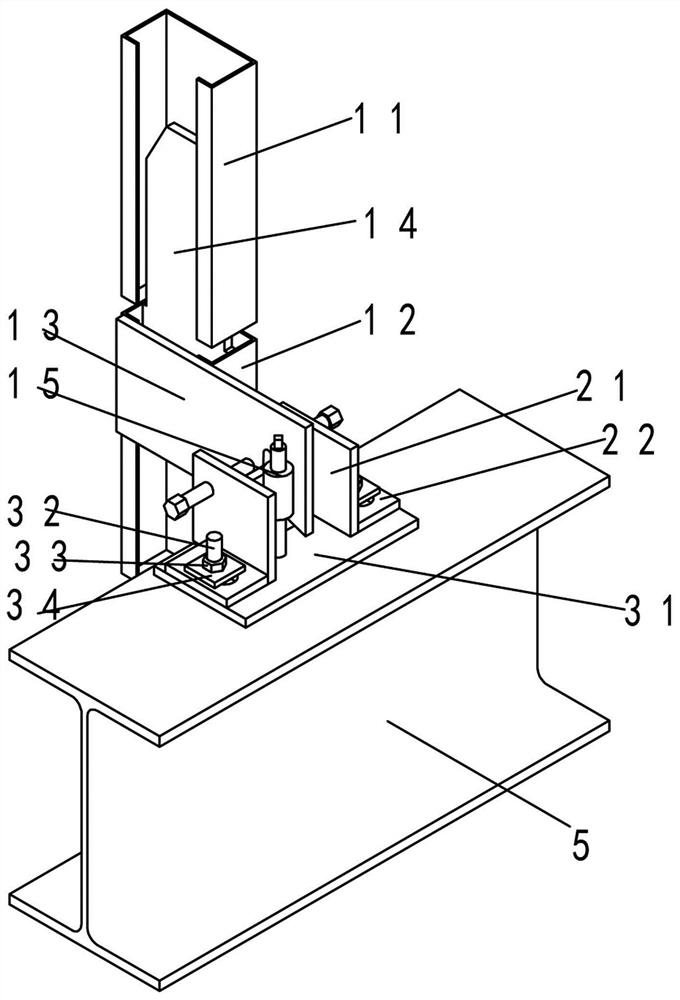

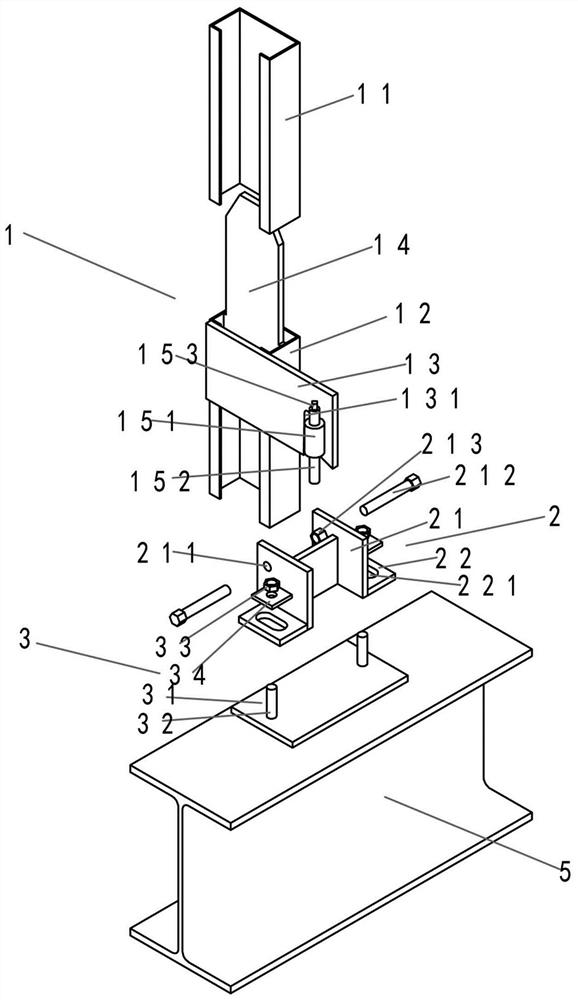

[0041] Embodiment two, still as Figures 1 to 4 As shown, it is only one of the embodiments of the present invention. In a plug-in light steel external wall panel connection node of the present invention, the number of the load-bearing member 15 is at least one. Generally speaking, both sides of the vertical plate 13 are A load-bearing member 15 can be provided, and the end of the load-bearing screw 152 is provided with a screw head 153 , the outer side of the load-bearing screw 152 is provided with external threads, and the inner wall of the load-bearing cylinder 151 is provided with internal threads. The load-bearing screw 152 is screwed to the load-bearing cylinder 151. By using a wrench to twist the screw head 153, the load-bearing screw 152 can be rotated in the load-bearing cylinder 151, thereby changing the length of the load-bearing screw 152 extending downward and changing the wall to be installed. The height of the plate is the Z-direction displacement adjustment.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com