Flexible hydrophilic polymer capable of adsorbing-desorbing anions and cations, and preparation method and application of flexible hydrophilic polymer

A hydrophilic polymer, anion and cation technology, applied in the field of flexible hydrophilic polymer materials, can solve the problems of incomplete decolorization and COD removal, unsatisfactory effect, long process time, etc., to achieve broad application and development prospects, Strong compatibility and adaptability, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

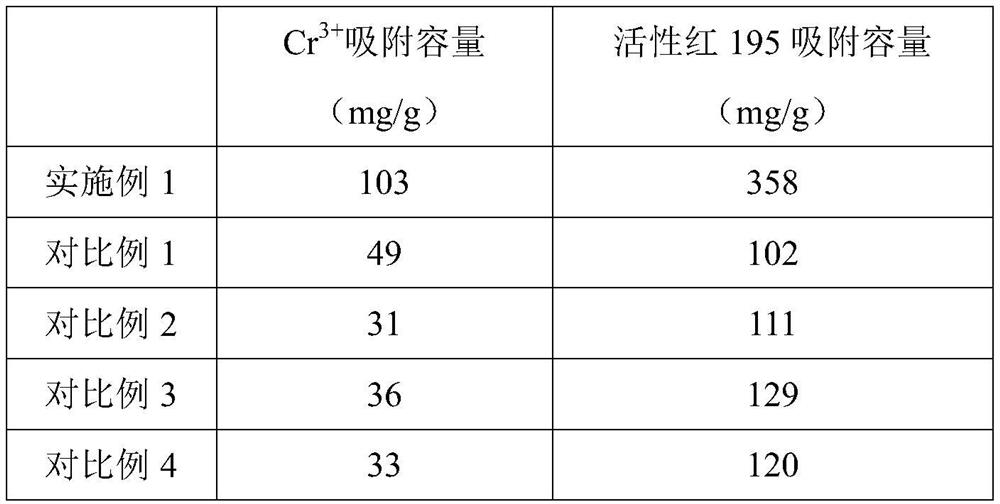

Examples

Embodiment 1

[0027] A method for preparing a flexible hydrophilic polymer with adsorption-desorption anions and cations, comprising the following steps:

[0028] (1) Take 4mmol cyanuric chloride and dissolve it in 80mL acetone to obtain a cyanuric chloride solution, weigh 8mmol 1,4-butanediol and dissolve it in 60mL acetone to obtain a 1,4-butanediol solution, protect it under nitrogen and Add the cyanuric chloride solution dropwise to the 1,4-butanediol solution under the condition of an ice-water bath, stir and react at 300r / min for 2h, then raise the temperature to 50°C, stir and react at 300r / min for 4h, then raise the temperature to 95°C, Stir and react at 300r / min for 6h, continuously add sodium carbonate during the reaction to maintain the pH at 6, and obtain a first-generation polymer crude product; extract and wash the first-generation polymer crude product three times with acetone, and vacuum filter to obtain a first-generation polymer;

[0029] (2) With cyanuric chloride as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com