Cold-rolling leveling waste liquid treatment method based on forward osmosis theory

A treatment method and leveling liquid technology, which is applied in the direction of metallurgical wastewater treatment, filtration treatment, special treatment goals, etc., can solve the problems of long cultivation and acclimation time, sludge loss, and treatment efficiency to be further improved, and achieve good economic benefits and environmental protection Efficiency, simple process, safe processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

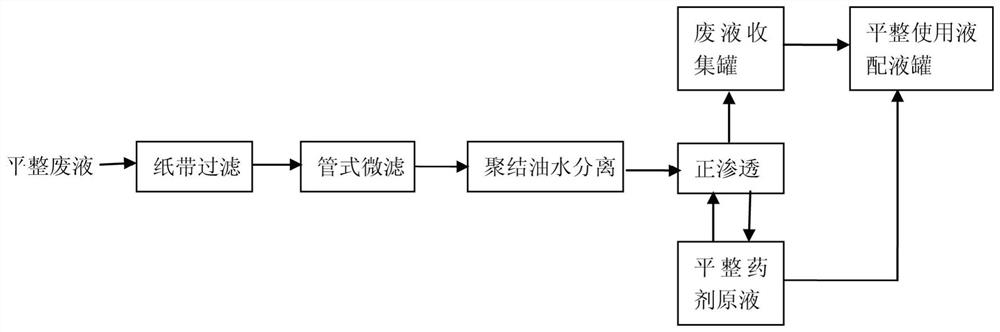

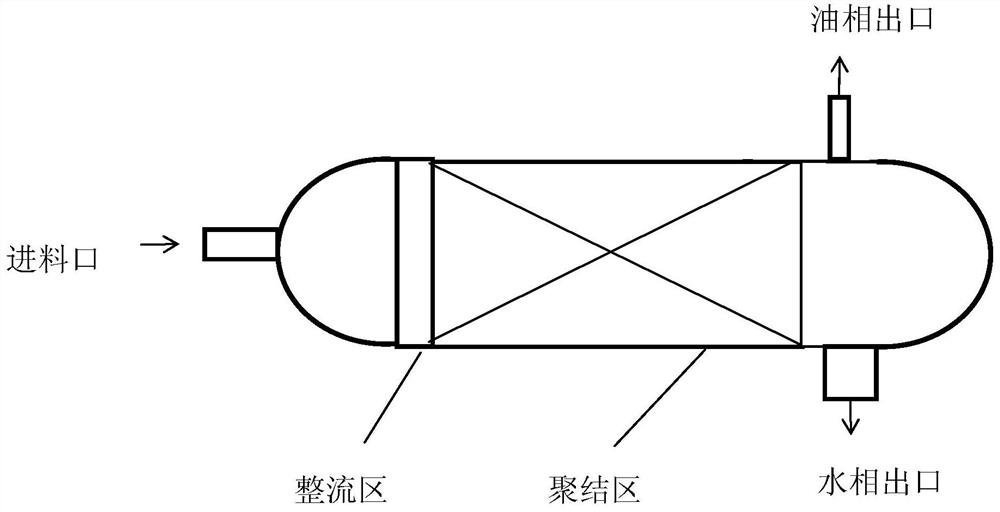

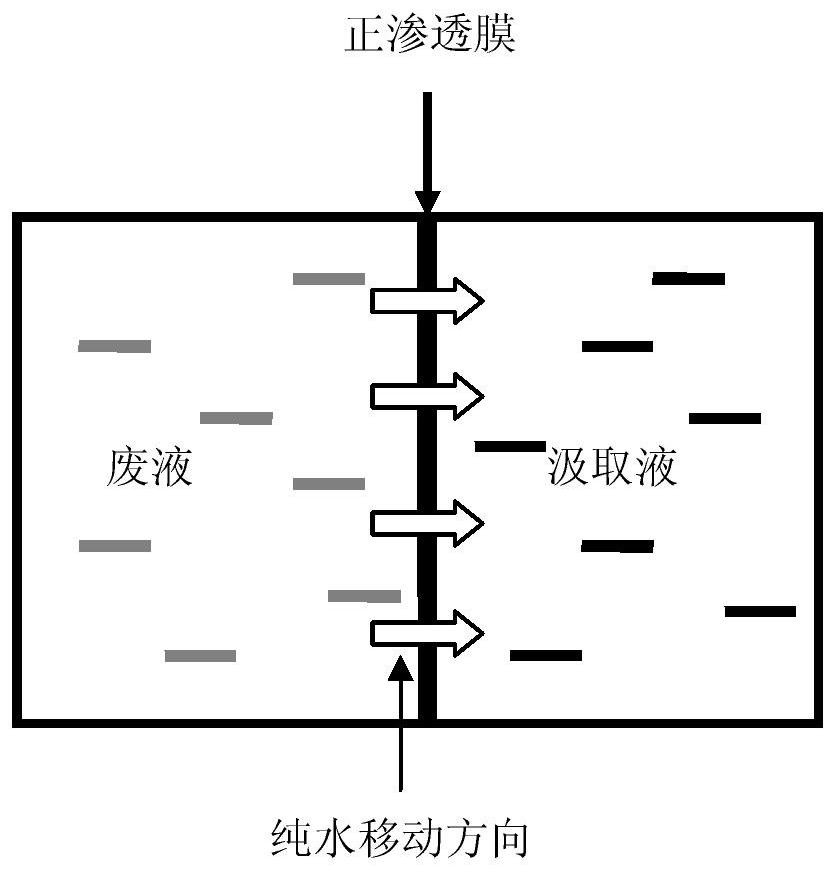

[0029] The invention provides a treatment method for cold-rolled leveling waste liquid based on forward osmosis theory, which comprises the process steps of filtering, oil-water two-phase separation and forward osmosis. The system is sequentially connected with a paper tape filter, a tubular microfiltration, a coalescing oil-water separator, and a forward osmosis device. The forward osmosis device is connected with a draw liquid circulation device and a recovery device for treated waste leveling liquid. The invention aims at the recycling process of cold-rolling leveling waste liquid, effectively removes the two main pollutants of particles and oil in the leveling waste liquid, effectively reduces the consumption of a large amount of new water used to dilute the original liquid of the leveling agent in the leveling process, and also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com