Non-woven fabric film wrapping packaging mechanism and non-woven fabric strip cigarette packaging system

A non-woven and film-wrapped technology, which is applied in the field of non-woven film-wrapped packaging mechanisms and non-woven cigarette packaging systems, can solve the problems of endangering the health of workers, volatilizing harmful gases, and high production costs, so as to reduce processing costs , Reduce production costs, simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

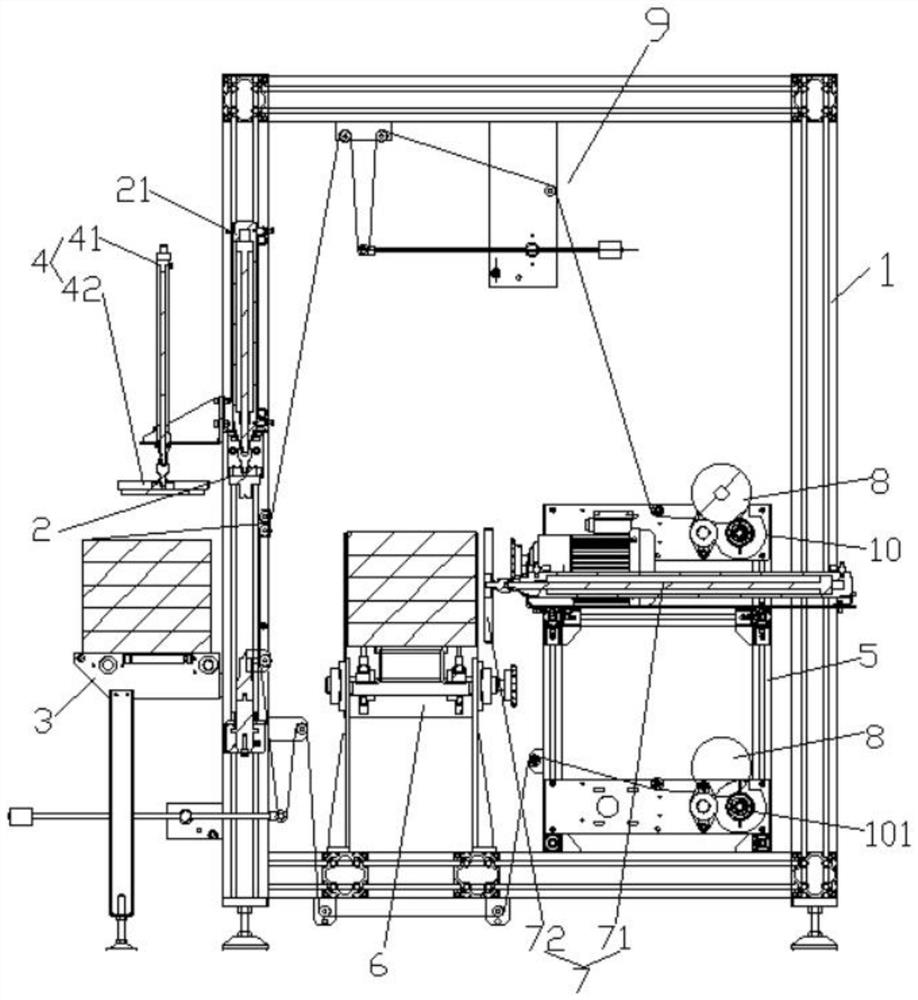

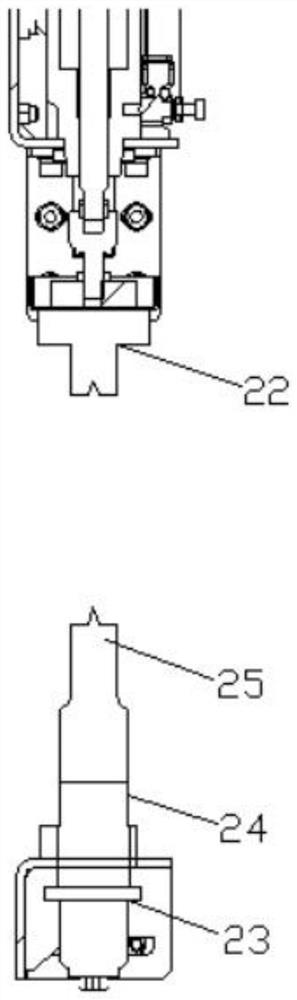

[0034] Example 1: as figure 1 and 2 As shown, the non-woven film wrapping and packaging mechanism of this embodiment includes a support frame 1, an ultrasonic sealing and cutting mechanism 2, a packaging table 3, a telescopic pressing and positioning device 4, a bracket 5, a material table 6 and a material pushing device 7. The above-mentioned ultrasonic sealing and cutting The mechanism 2 is assembled on the above-mentioned support frame 1, and is used for welding and cutting two non-woven fabrics distributed up and down through it. The above-mentioned packaging table 3 is arranged in front of the above-mentioned ultrasonic sealing and cutting mechanism 2. It is arranged above the above-mentioned packaging table 3, and is used to press the material on the upper end of the packaging table 3. The above-mentioned support 5 is arranged behind the above-mentioned ultrasonic sealing and cutting mechanism 2, and two non-woven rolls 8 are arranged at an upper and lower interval. The...

Embodiment 2

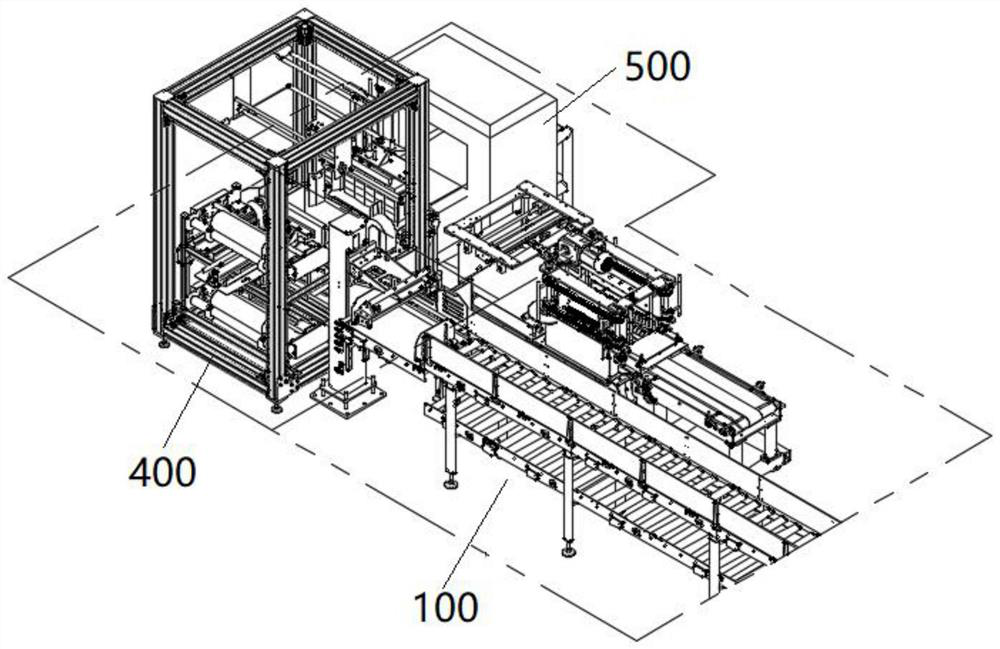

[0060] Embodiment two, as image 3 As shown, the non-woven cigarette packaging system of this embodiment includes a stacking system 100, the non-woven film wrapping and packaging mechanism 400 and the packaging system 500 in the first embodiment, and the above-mentioned stacking system 100 is arranged on the above-mentioned non-woven fabric. The side of the material table 6 of the film wrapping mechanism 400 is used for stacking and transporting the cigarettes to the upper end of the material table 6, and the packaging system 500 is used for receiving the film-wrapped cigarette stacks on the packaging table 3 and packaging and packaging. .

[0061] During the production process, the cigarettes are stacked and stacked according to the requirements at the stacking system 100. After the stacking is completed, they are sent to the material table 6. After that, the non-woven film wrapping and packaging mechanism 400 wraps the stack to process the non-woven fabric. After finishing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com