Novel nickel-iron electrolysis water oxygen production catalyst and preparation method thereof

A technology of oxygen catalyst and nickel-iron, which is applied in the field of electrocatalysis, can solve the problems of low intrinsic activity of oxygen production, complex preparation process, and difficult process, and achieve the effect of excellent oxygen production activity, simple preparation method and high intrinsic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

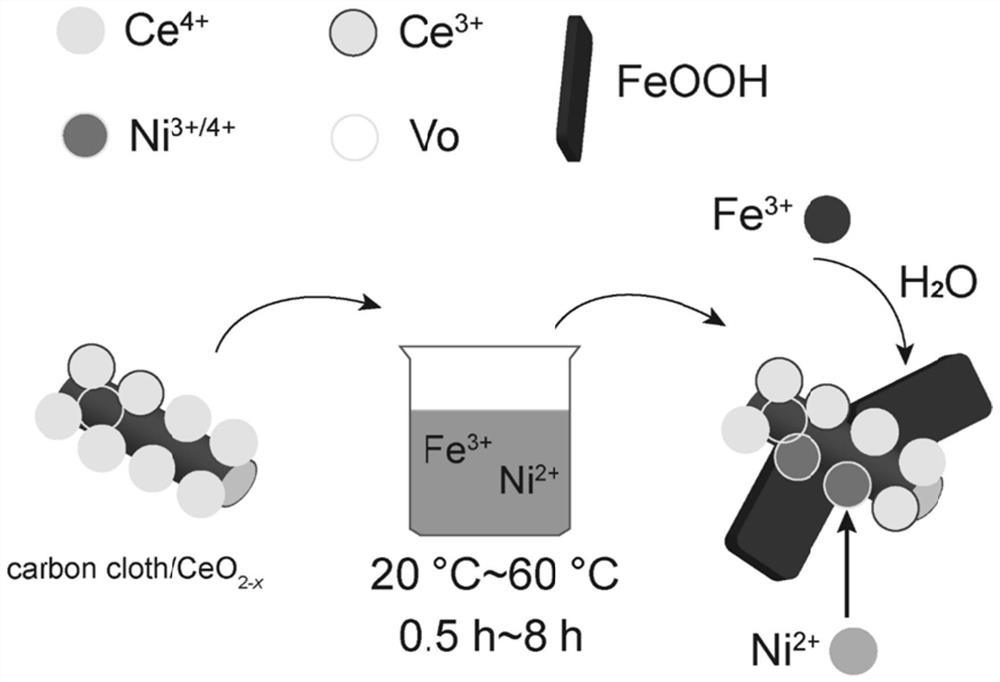

[0044] A novel nickel-iron electrolysis water oxygen production catalyst, its preparation method comprises the following steps:

[0045] (1) Using carbon cloth as the substrate and a mixed solution of 2mM cerium nitrate and 10mM sodium chloride as the electrolyte, CeO was prepared by electroplating 2 Carbon cloth, electroplating conditions: electrodeposition current is 0.25 mA / cm 2 , the electrodeposition time is 20min, and the temperature is 70℃;

[0046] (2) CeO2 film at 10%H 2 / Ar 500℃ for 2h to obtain CeO rich in oxygen vacancies 2-x Carbon cloth, where x is 1.5;

[0047] (3) The CeO rich in oxygen vacancies 2-x The carbon cloth is immersed in a mixed solution of nickel nitrate and ferric nitrate for treatment, wherein the total concentration of metal ions in the mixed solution is 0.1M, the treatment time is 0.5h, and the treatment temperature is 60°C;

[0048] (4) Take it out and wash it with ultrapure water several times, then dry it naturally in the air to get CeO ...

Embodiment 2

[0051] A novel nickel-iron electrolysis water oxygen production catalyst, its preparation method comprises the following steps:

[0052] (1) Using carbon cloth as the substrate and a mixed solution of 2mM cerium nitrate and 10mM sodium chloride as the electrolyte, CeO was prepared by electroplating 2 Carbon cloth, electroplating conditions: electrodeposition current is 0.25 mA / cm 2 , the electrodeposition time is 20min, and the temperature is 70℃;

[0053] (2) CeO 2 film at 10%H 2 / Ar 500℃ for 2h to obtain CeO rich in oxygen vacancies 2-x Carbon cloth, where x is 1.2;

[0054] (3) The CeO rich in oxygen vacancies 2-x The carbon cloth is soaked in a mixed solution of nickel nitrate and ferric nitrate for treatment, wherein the total concentration of metal ions in the mixed solution is 0.1M, the treatment time is 4h, and the treatment temperature is 40°C;

[0055] (4) Take it out and wash it with ultrapure water several times, then dry it naturally in the air to get CeO 2...

Embodiment 3

[0057] A novel nickel-iron electrolysis water oxygen production catalyst, its preparation method comprises the following steps:

[0058] (1) Using carbon cloth as the substrate and a mixed solution of 2mM cerium nitrate and 10mM sodium chloride as the electrolyte, CeO was prepared by electroplating 2 Carbon cloth, electroplating conditions: electrodeposition current is 0.25 mA / cm 2 , the electrodeposition time is 20min, and the temperature is 70℃;

[0059] (2) CeO 2 film at 10%H 2 / Ar 500℃ for 2h to obtain CeO rich in oxygen vacancies 2-x Carbon cloth, where x is 1.8;

[0060] (3) The CeO rich in oxygen vacancies 2-x The carbon cloth is immersed in a mixed solution of nickel nitrate and ferric nitrate for treatment, wherein the total concentration of metal ions in the mixed solution is 0.1M, the treatment time is 8 hours, and the treatment temperature is 20°C;

[0061] (4) Take it out and wash it with ultrapure water several times, then dry it naturally in the air to get...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com