Gas-liquid distribution device

A gas-liquid distribution and distribution plate technology, which is applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problem of short contact time between gas and liquid, small spraying area of gas and liquid, and poor ability of gas-phase atomization and liquid-phase. and other problems, to avoid uneven distribution, good liquid phase ability, and promote dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

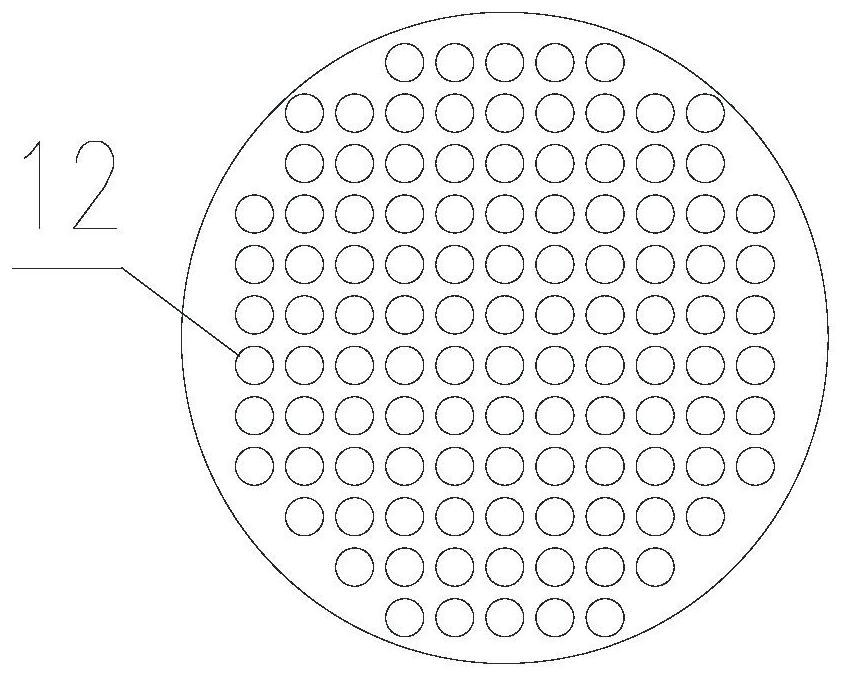

[0028] Such as figure 1 As shown, the gas-liquid distribution device of the present invention mainly includes an umbrella cap 1, an overflow pipe 5 and a distribution plate 6 arranged from top to bottom; the umbrella cap 1 is a tapered umbrella and is located at the upper end of the overflow pipe 5; The tube 5 is a round tube with both ends open, the lower end is fixed on the installation hole of the distribution plate 6, and the gas phase channel 2 is provided at the connection with the umbrella cap 1, and one or two or more layers are evenly opened on the tube wall along the circumferential direction The overflow hole 3 is used as a liquid phase channel, and a liquid collecting pan 4 is arranged under each overflow hole in the overflow pipe 5. The liquid collecting pan 4 is a concave flat-bottomed disc, and the raised concave edge meets the wall of the overflow pipe 5. Fixed connection, distribution holes evenly distributed on the bottom of the liquid collection pan, for gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com