Continuous casting method of steel

A casting machine and cast slab technology, which is applied in metal rolling and other directions, can solve the problems of less reduction, the influence of center segregation, and the inability to improve center segregation, so as to achieve the effect of improving performance and reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

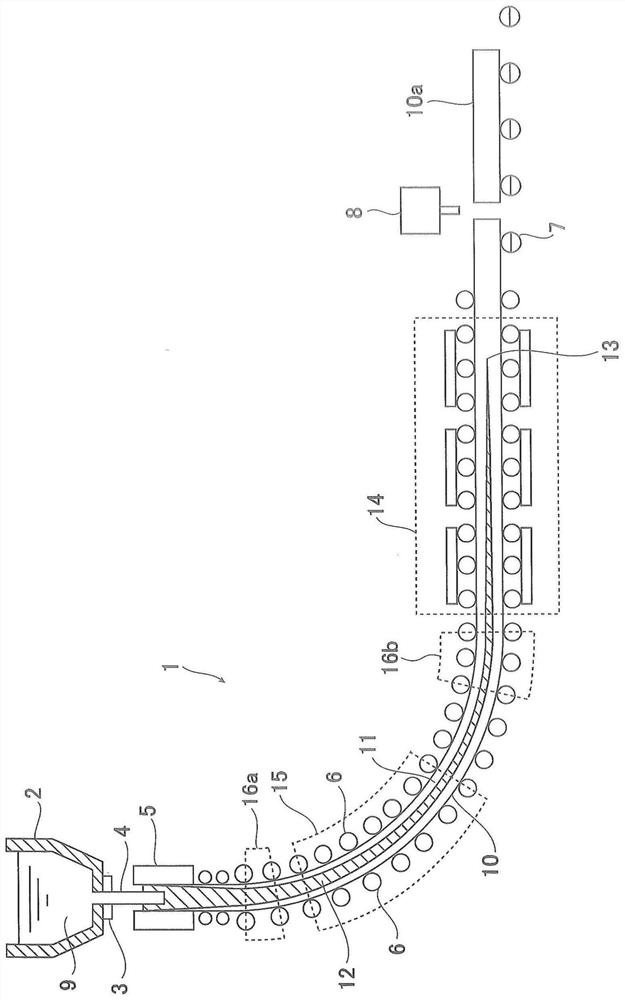

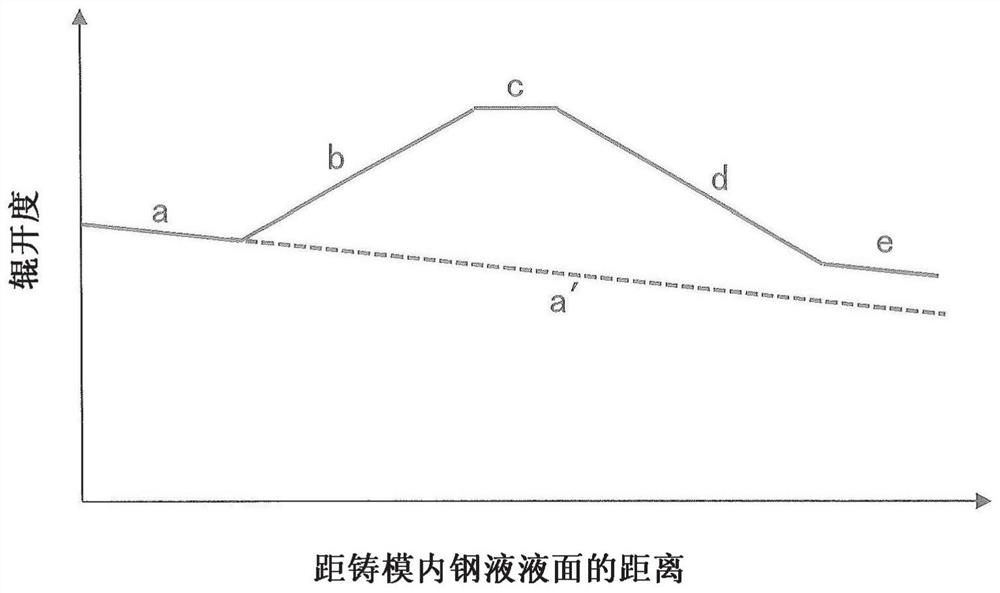

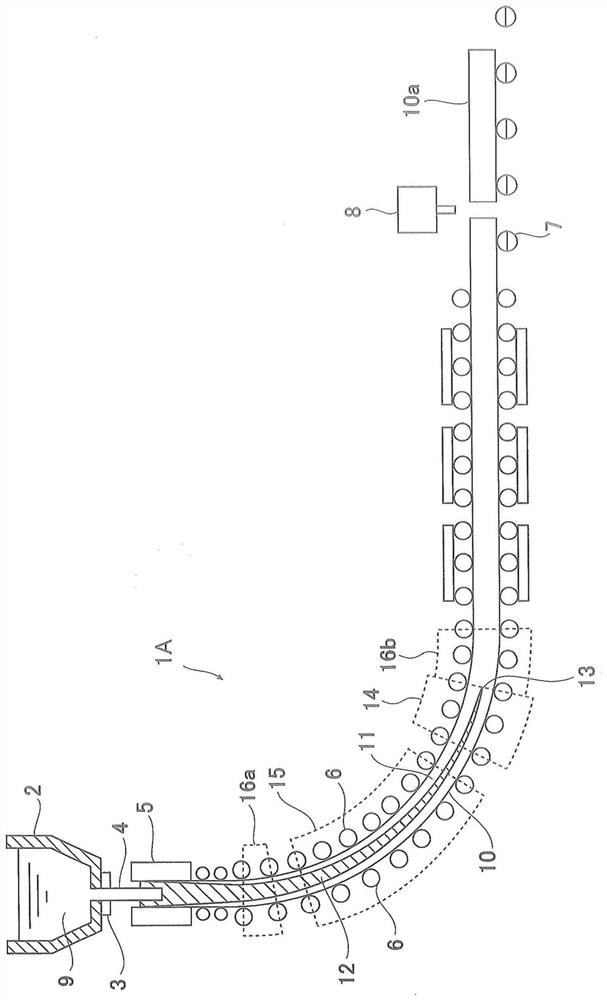

[0093] The inventors of the present invention conducted a test (grades 101 to 113) of casting a slab 10 (slab slab) with a width of 2100 mm and a thickness of 250 mm with the aim of effectively lightly reducing the slab 10 . In the test, the casting speed was fixed at 1.1 m / min, and the total amount of intentional swelling in the intentional swelling zone 15 and the reduction speed in the soft reduction zone 14 were changed. Then, the effects of the total amount of intentional swelling, the reduction speed and the total reduction on the quality of cast slabs were investigated. In addition, the solid fraction at the center of the slab thickness in the correction zone 16b is 0 to 0.1.

[0094] The Mn segregation degree of the obtained slab 10 was investigated, and the hydrogen-induced cracking resistance test of the obtained slab 10 was implemented. Table 2 shows casting conditions and investigation results.

[0095] [Table 2]

[0096]

[0097] In the test, the total amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com