Non-contact film water-oxygen permeability testing device and production process thereof

A non-contact, testing device technology, applied in the direction of electrical components, circuits, material excitation analysis, etc., to achieve the effect of good safety, reliable data, and low condition requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

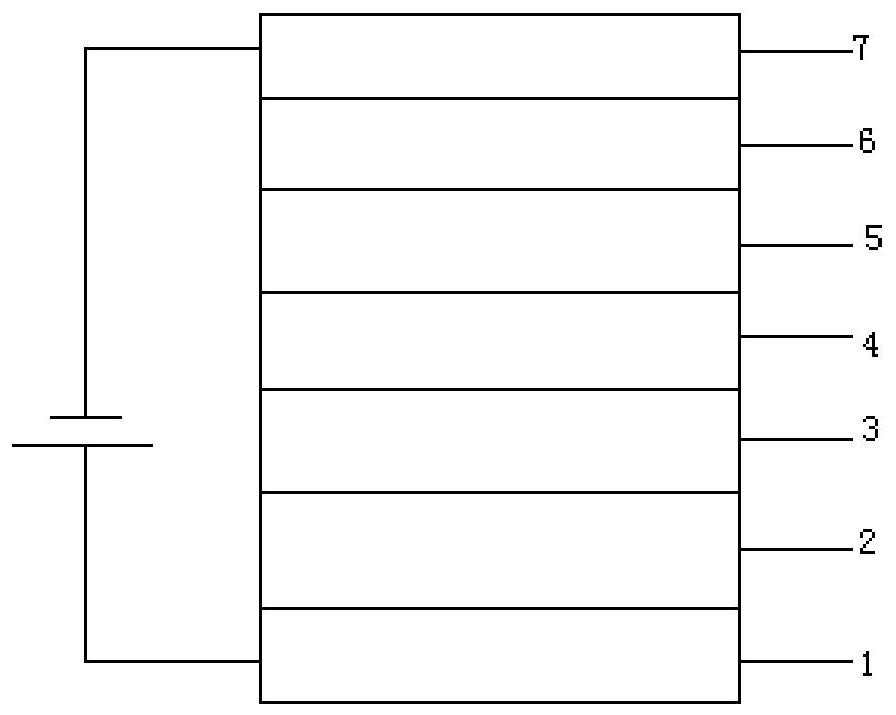

[0025] refer to figure 1 The present invention relates to a non-contact membrane water-oxygen permeation performance test device and its production process.

[0026] Non-contact film water oxygen transmission performance test device, including Al 2 o 3 substrate, in Al 2 o 3 An undoped u-GaN buffer layer is grown on the substrate, a Si-doped n-GaN epitaxial layer is grown on the u-GaN buffer layer, and In0.2Ga0.8N / GaN multiquantum is grown on the n-GaN epitaxial layer Well layer, on the In0.2Ga0.8N / GaN multi-quantum well layer, an organic red light material layer and a hole transport layer are sequentially evaporated, and the hole transport layer is provided with electrodes.

[0027] Undoped u-GaN buffer layer in this embodiment: used to alleviate the lattice mismatch between the sapphire substrate and GaN; Si-doped n-GaN epitaxial layer: multiple quantum well layers can be grown on this layer , Si-doped n-GaN matches better with multiple quantum wells and is more suitabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com