A kind of anti-radiation reinforced SOI device based on neutron irradiation and its preparation method

A radiation-resistant hardening and device technology, which is applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor/solid-state device components, etc., can solve the problem of difficult control of SiGe junction depth, increase device active area area, and lead-out effect To achieve the effect of restoring carrier lifetime and mobility, saving process cost, and reducing parasitic bipolar amplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

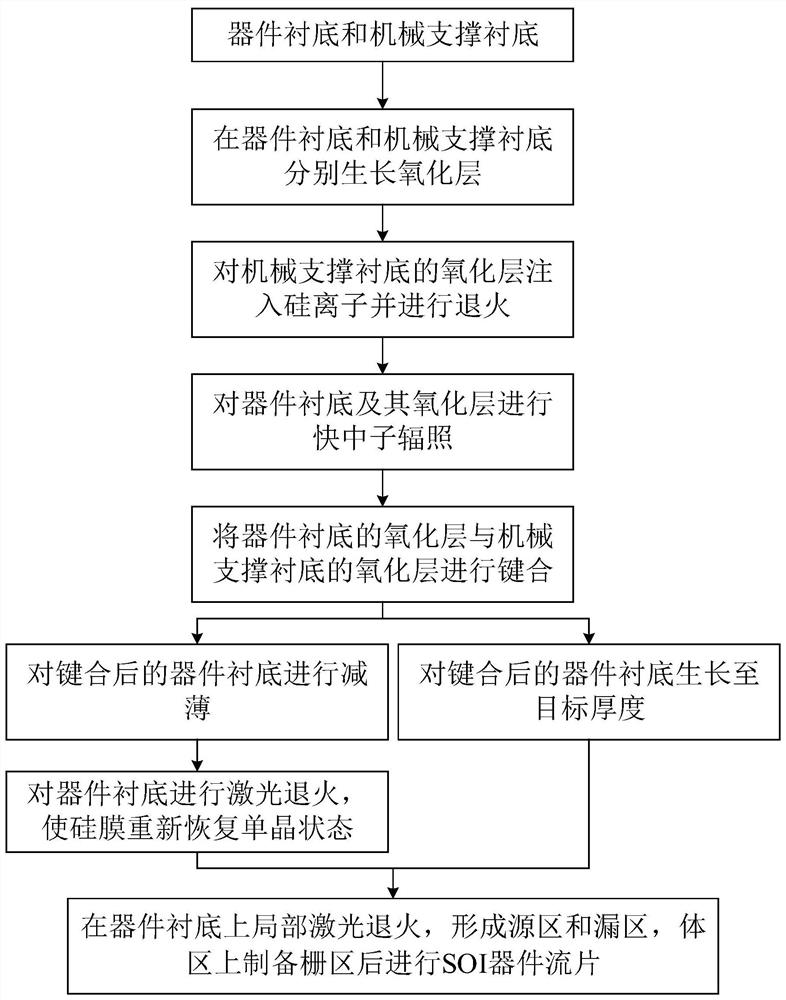

Method used

Image

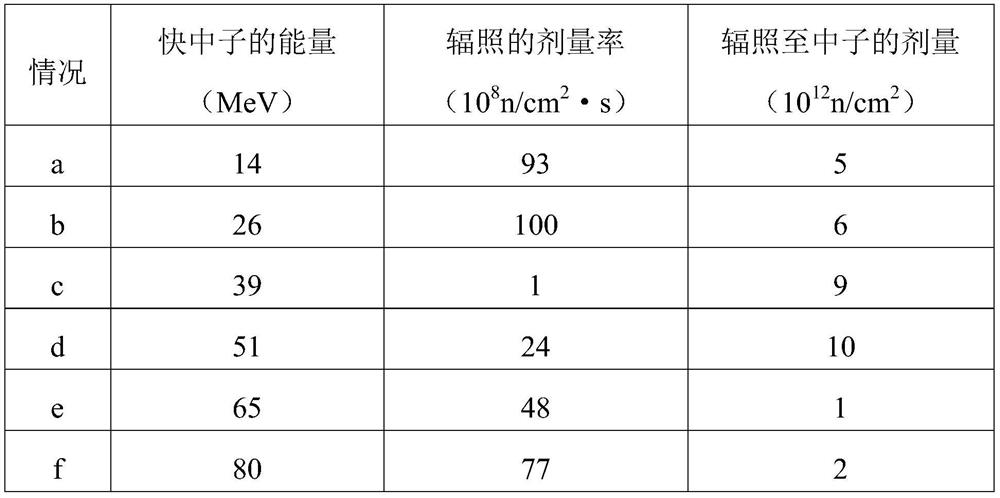

Examples

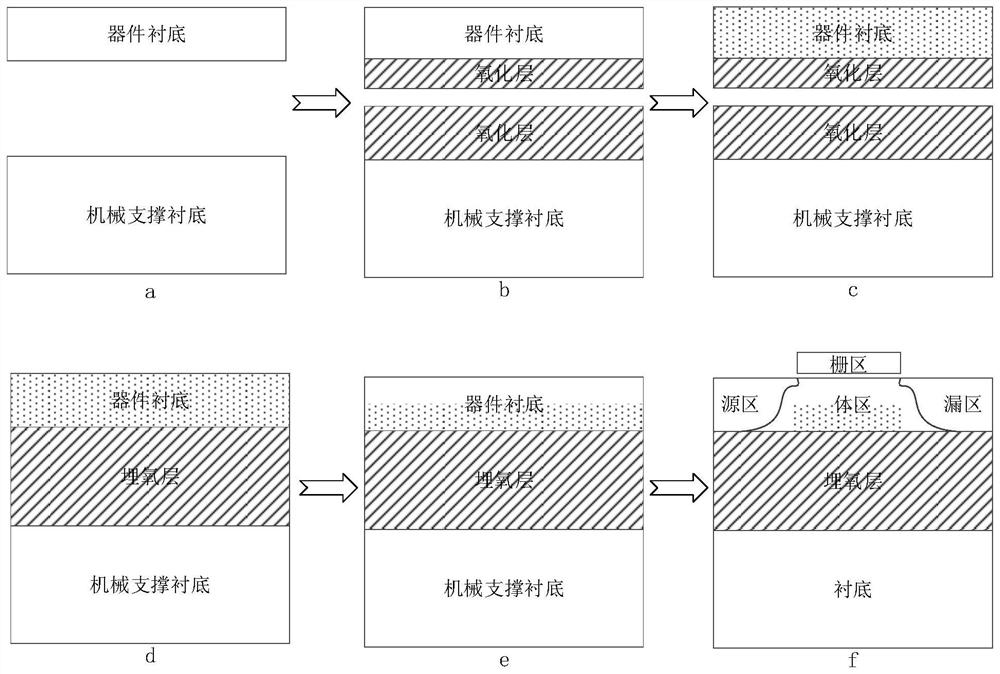

preparation example Construction

[0045] Or use chemical vapor deposition to grow a single crystal of silicon, so that the silicon layer extends outward to the desired

[0046] So that the surface conduction channel restores a good carrier mobility.

[0055] 6. Laser annealing is performed on the surface of the silicon layer of the device by means of laser annealing. Excimer CW KrF laser

[0058] The present invention can form any

Embodiment 1

[0064] step 4, the device substrate after bonding is processed, so that the surface layer of the silicon layer is restored to a single crystal state;

Embodiment 2

[0067] On the basis of Example 1, an oxide layer is formed on the surface of the device substrate using a thermal oxidation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com