Multilayer ceramic capacitor and its preparation method

A technology of multilayer ceramics and capacitors, which is applied in the direction of laminated capacitors, fixed capacitor electrodes, fixed capacitor parts, etc., can solve problems such as increased labor costs, high equivalent series resistance and high frequency loss, and extended production cycles. Achieve the effects of convenient sorting, low equivalent series resistance and high frequency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

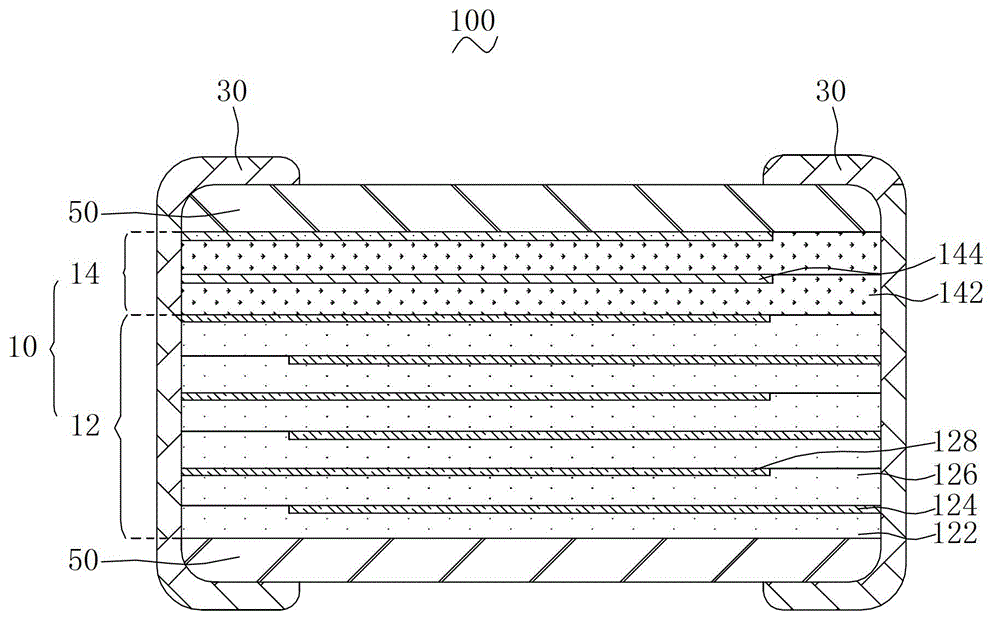

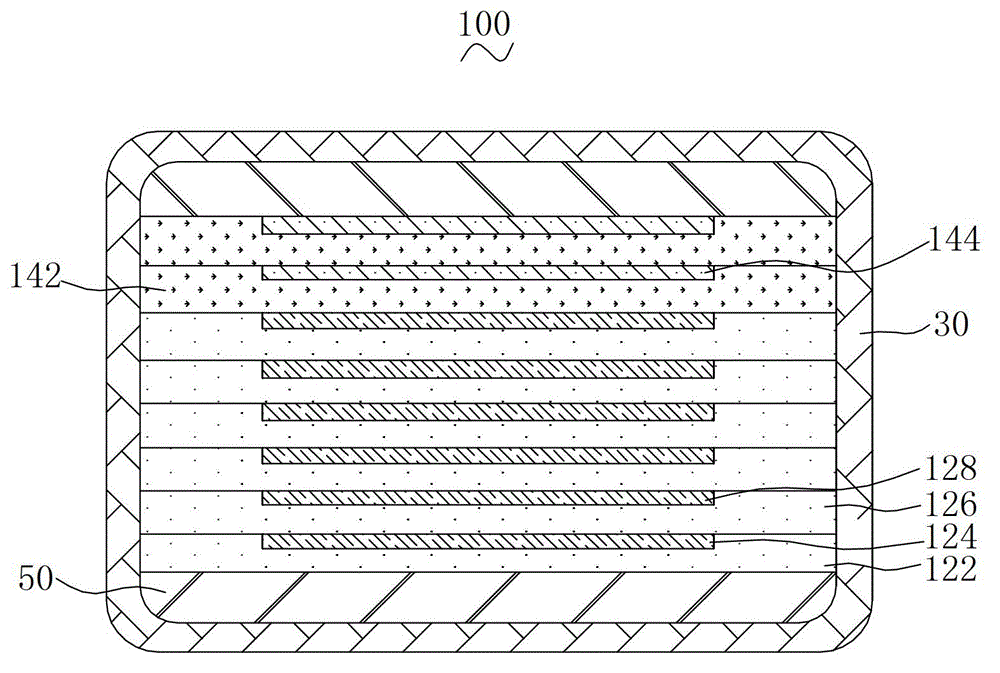

[0124] see Figure 7 , the preparation method of the multilayer ceramic capacitor of an embodiment, comprises the steps:

[0125] Step S110: preparing a plurality of ceramic membranes.

[0126] The ceramic powder, the organic binder and the organic solvent are mixed and ball-milled to form a uniform ceramic slurry, and the ceramic slurry is formed into multiple ceramic films by casting.

[0127] The mass ratio of ceramic powder, organic binder and organic solvent is 10:3-5:6-9. Among them, the main component of the ceramic powder is calcium zirconate or strontium zirconate; the organic binder is polyvinyl butyral; the organic solvent is a mixed solvent of toluene and ethanol, wherein the volume ratio of toluene and ethanol is preferably 1:1 ~2:1.

[0128] Step S120 : preparing a plurality of ceramic membranes laminated with the first capacitance electrode membrane, a plurality of ceramic membranes laminated with the second capacitance electrode membrane, and a plurality of ...

Embodiment 1

[0149] Fabrication of Multilayer Ceramic Capacitors

[0150] 1. Mix the ceramic powder whose main component is calcium zirconate, polyvinyl butyral, toluene and ethanol at a volume ratio of 1.5:1, mix and ball mill at a mass ratio of 10:3:6 to form a uniform ceramic Slurry, casting the ceramic slurry to form a plurality of ceramic membranes by a casting method;

[0151] 2. Print copper metal paste and nickel metal paste on the ceramic film independently by screen printing process to form a predetermined internal electrode pattern, and form multiple ceramic films laminated with the first capacity electrode film after drying , a plurality of ceramic membranes laminated with second capacity electrode membranes and a plurality of ceramic membranes laminated with additional electrode membranes;

[0152] 3. Alternately stacking one ceramic film laminated with the first capacity electrode film and one ceramic film laminated with the second capacity electrode film to obtain a laminat...

Embodiment 2

[0160] Fabrication of Multilayer Ceramic Capacitors

[0161] 1. Mix the ceramic powder whose main component is calcium zirconate, polyvinyl butyral, toluene and ethanol at a volume ratio of 2:1, mix and ball mill at a mass ratio of 10:5:9 to form a uniform ceramic Slurry, casting the ceramic slurry to form a plurality of ceramic membranes by a casting method;

[0162] 2. Print copper metal paste and nickel metal paste on the ceramic film independently by screen printing process to form a predetermined internal electrode pattern, and form multiple ceramic films laminated with the first capacity electrode film after drying , a plurality of ceramic membranes laminated with second capacity electrode membranes and a plurality of ceramic membranes laminated with additional electrode membranes;

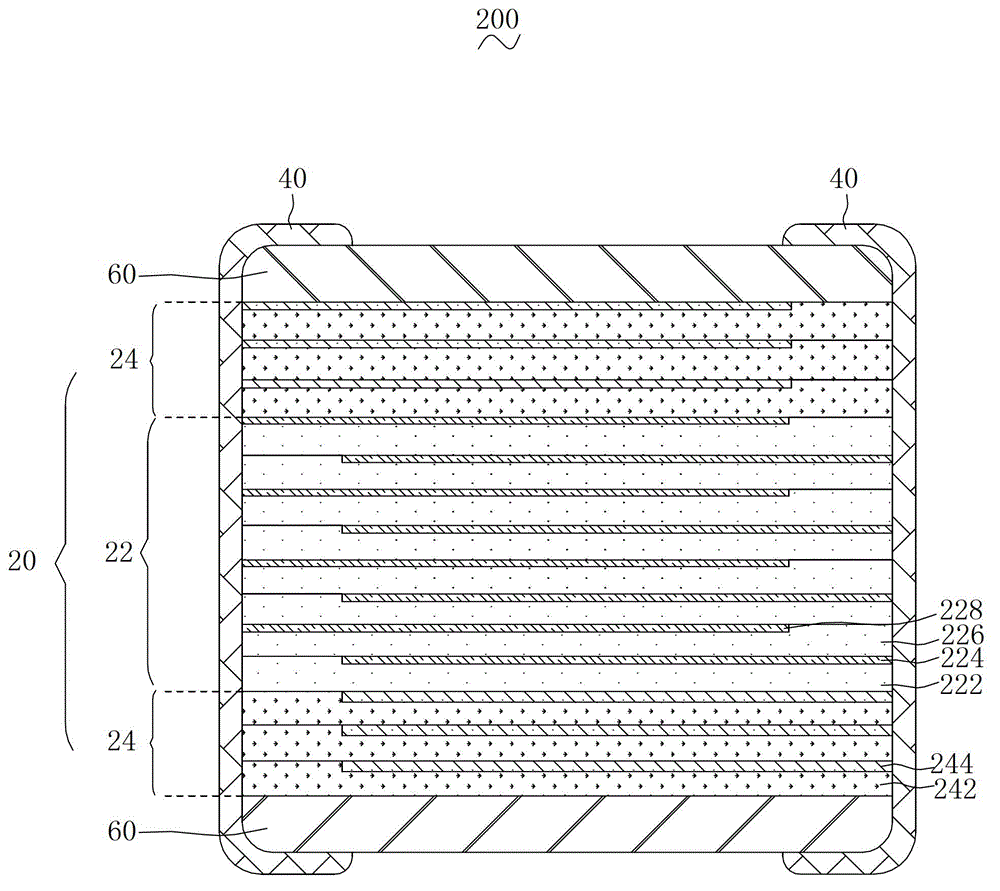

[0163] 3. Alternately stacking 25 ceramic films laminated with the first capacity electrode film and 25 ceramic films laminated with the second capacity electrode film to obtain a laminated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com