Tramcar prefabricated track beam and construction method

A technology for trams and track beams, which is applied to tracks, track superstructures, roads, etc., and can solve the problems of wasting manpower and material resources and not forming tram track beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

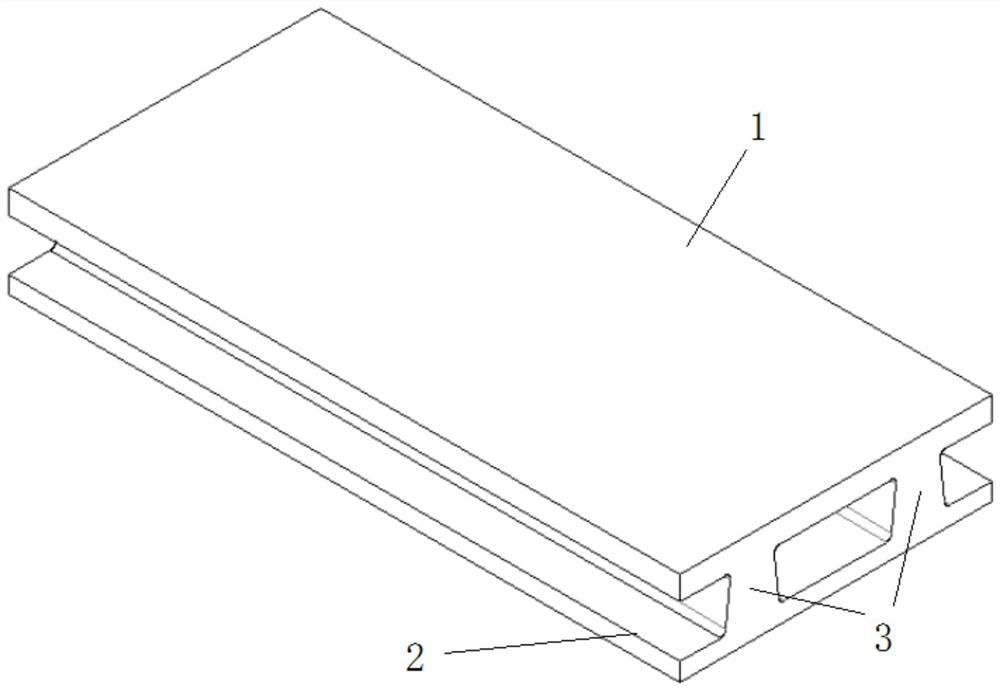

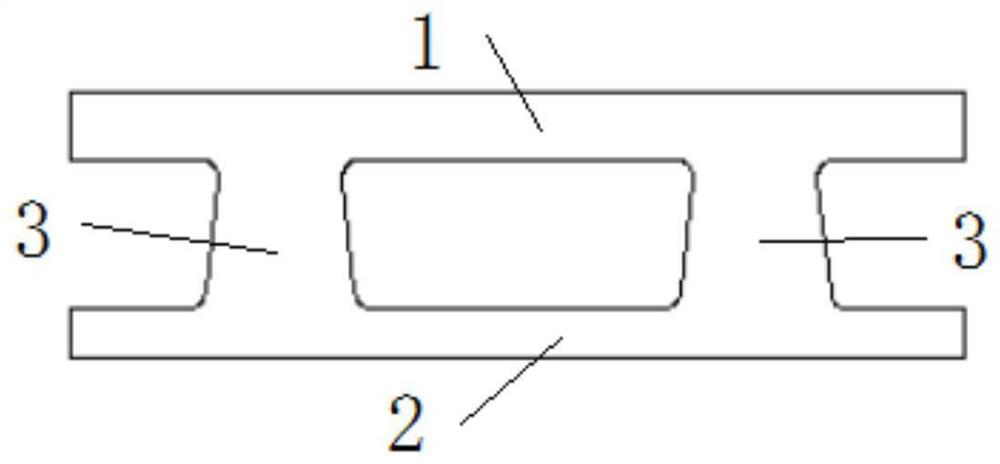

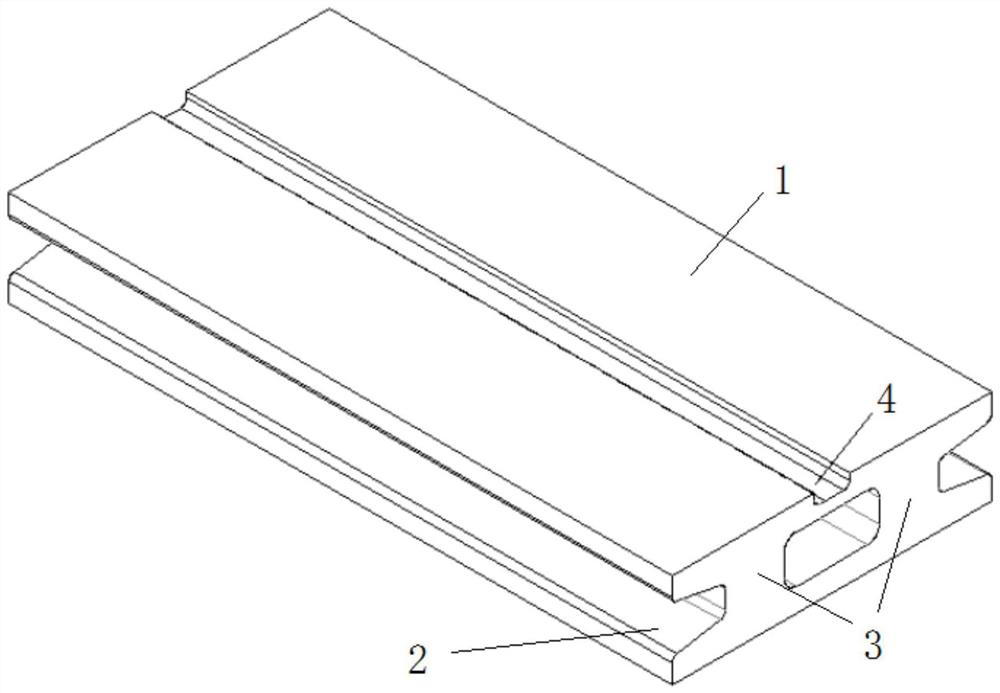

[0027] Such as figure 1 and figure 2 As shown, the prefabricated track girder of the tram includes an upper panel 1 and a lower panel 2 parallel to each other; there are at least two support parts 3 between the upper panel 1 and the lower panel 2, and every two adjacent support parts 3 The intervals between them are all greater than the width of the corresponding support portion 3 .

[0028] Principle of the present invention is as follows:

[0029] The overall weight is reduced through the middle and both sides of the support part 3, which is convenient for transportation; the track beam first needs to be manually woven with a steel cage that is similar in shape to the prefabricated part and has a smaller size, and then the woven steel cage is hoisted into the mold by driving and matched with the corresponding The parts are fixed, and then the prepared concrete is poured into the mold, vibrated and smoothed to form it.

[0030] In some embodiments, both the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com