Novel automatic aligning roller of belt conveyer

A belt conveyor and automatic adjustment technology, applied in the direction of conveyors, conveyor objects, rollers, etc., can solve the problem that the self-aligning idler is not easy to adjust, and achieves increased versatility and interchangeability, waterproof, reliable, and convenient. The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

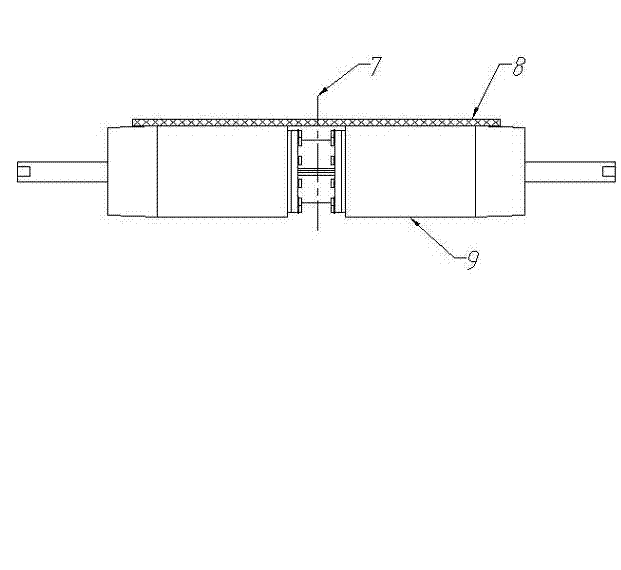

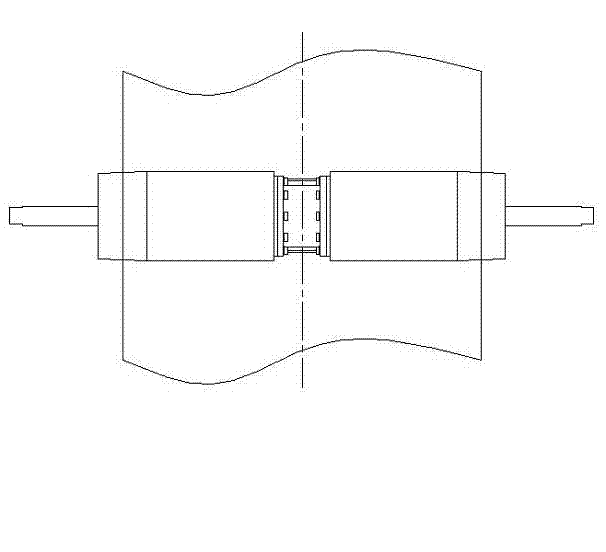

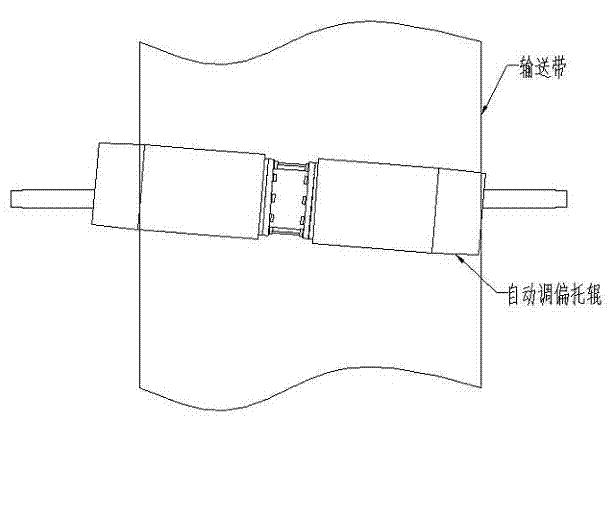

[0024] as attached Figure 4-6 As shown in the schematic diagram of the structure of the embodiment of the present invention, the automatic deflection roller of the present embodiment includes a rubber roller 1, a rubber sleeve 2, and a swing mechanism 3. The rubber roller 1 is divided into two symmetrical rubber rollers. The mechanism 3 is located between the two rubber rollers, put the rubber sleeve 2 on the central pendulum shaft 39, and fasten the rubber roller 1 and the swing mechanism 3 with screws 4 and spring washers 5 . Assemble the other side as well.

[0025] The structural representation of the rocking mechanism 3 of the central part is shown in the attached Figure 7-9 . Pass the center swing shaft 39 through the inner sleeve 35; then pass the cylindrical pin 38 through the inner sleeve 35, the center sleeve 36 and the center s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com