Constant-temperature ladle for vacuum suction and injection of liquid rare earth metal

A technology of rare earth metal and vacuum injection, applied in electrolysis process, electrolysis components, etc., can solve the problems of reduced production, complicated operation, large equipment, etc., and achieve the effect of avoiding slagging, avoiding metal oxidation, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

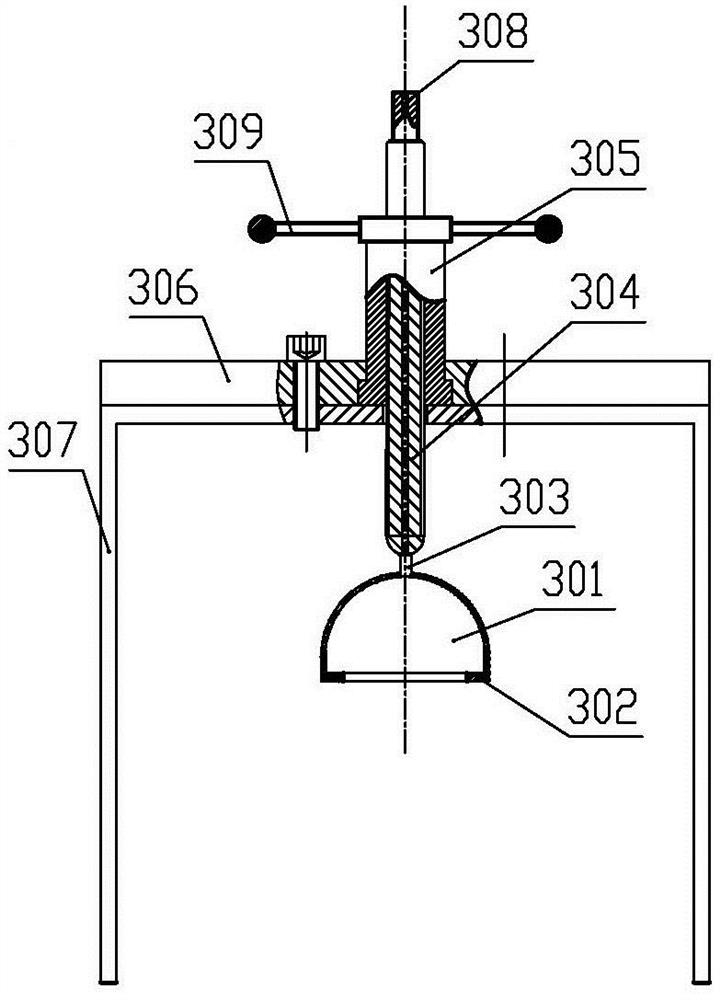

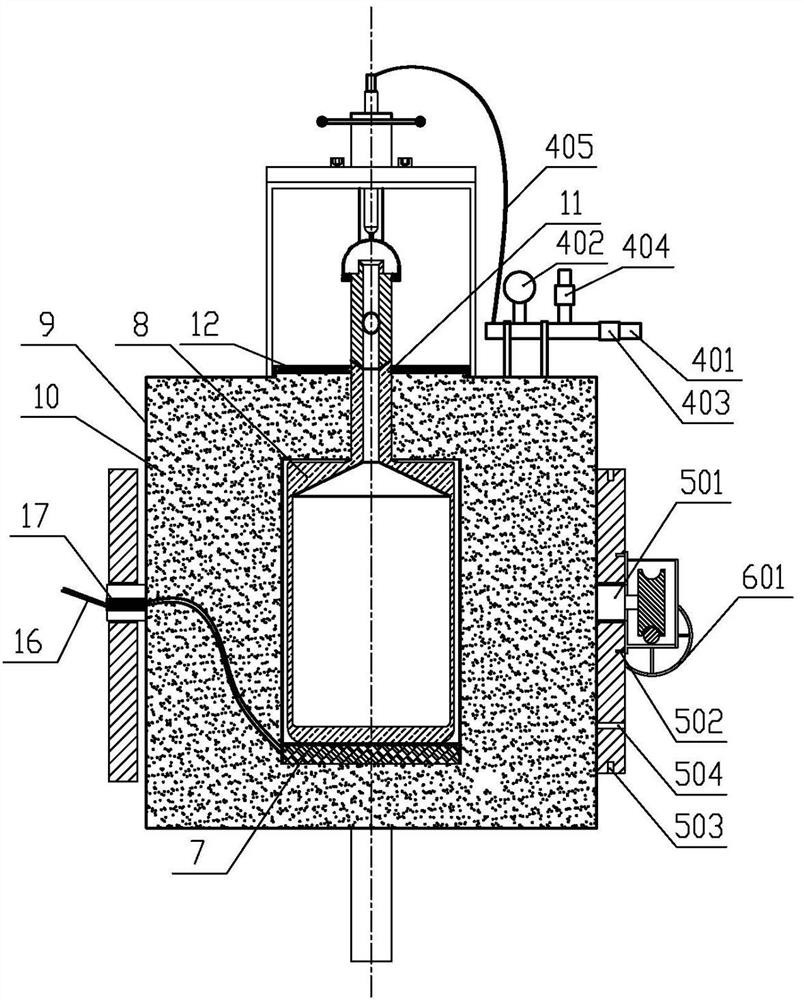

[0029] Embodiment 1: When the present invention is used in the production of liquid rare earth metals by electrolysis, prepare the components mentioned above before operation and connect and assemble the components, and connect the liftable arm frame of the external plug-in car with the enclosure connector 5 Fix it well, fix the external vacuum pump with an air pumping capacity of 2.0 liters per second on the enclosure connector 5, and connect it with the vacuum valve 403 with the external vacuum connection pipe, and the external compressed nitrogen source pipe and pressure regulator The valve 404 is connected well, the total height of the present invention is 1880mm, the internal diameter of the liquid suction pipe 2 is 30mm, the inner chamber volume of the liquid storage liner 8 is 120 liters, and the total height of the inner chamber is 1.0 meters. When the present invention is used, turn the lifting handwheel 309 rotates the rotating sleeve 305, and then makes the straight-...

Embodiment 2

[0030] Embodiment 2: When the present invention is applied to take out liquid metals in different electrolytic cells respectively, pack them together, and carry out constant temperature pouring, the power line of the external temperature control equipment is connected to the wire of the electric heating plate 7 of the present invention, The external temperature control equipment is connected to the wire of the temperature measuring device, the power is turned on, the temperature control of the external temperature control equipment is set, and the method and steps of pumping liquid metal by the electrolytic cell are the same as those in the first embodiment above. At the end of the metal suction operation, adjust and move the externally equipped car to move the liquid suction pipe 2 of the present invention out of the electrolytic cell, and carry out the suction operation to the next electrolytic cell. The amount of molten metal in the gallbladder 8 reaches an appropriate value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com