Air film resistance reduction system and method and high-speed train

A technology of air film and air film hole, which is applied in the direction of railway car body, railway car body parts, climate sustainability, etc., can solve the problems of large processing volume and impact strength, achieve good aerodynamic performance, reduce medium resistance, reduce The effect of operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention is described in detail below in conjunction with examples, but the present invention is not limited to these examples.

[0062] In this article, the loading device refers to various existing tools that have the function of transporting large-volume materials such as goods or people, including but not limited to automobiles, high-speed trains, airplanes, torpedoes and other devices. Medium refers to the environmental substances in which the ride-on device operates, including but not limited to various liquids, various gases or various solid environments. The resistance-bearing surface refers to the surface of the load-carrying device that mainly bears the resistance from the environmental medium during operation. The main resistance-bearing surface refers to the surface of the load-carrying device that bears the greatest resistance from the environmental medium.

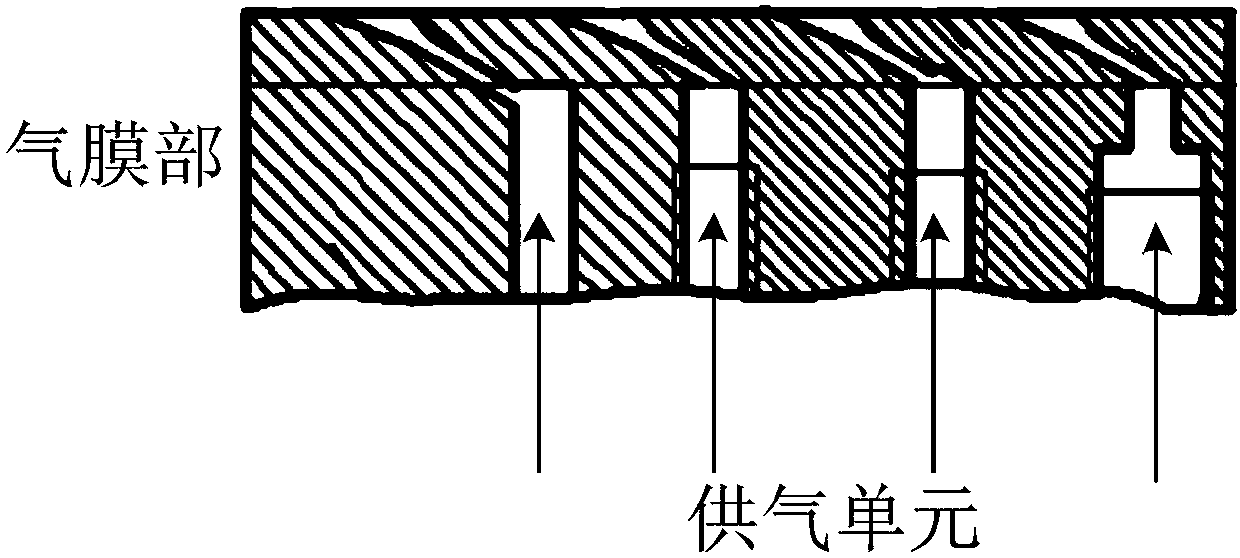

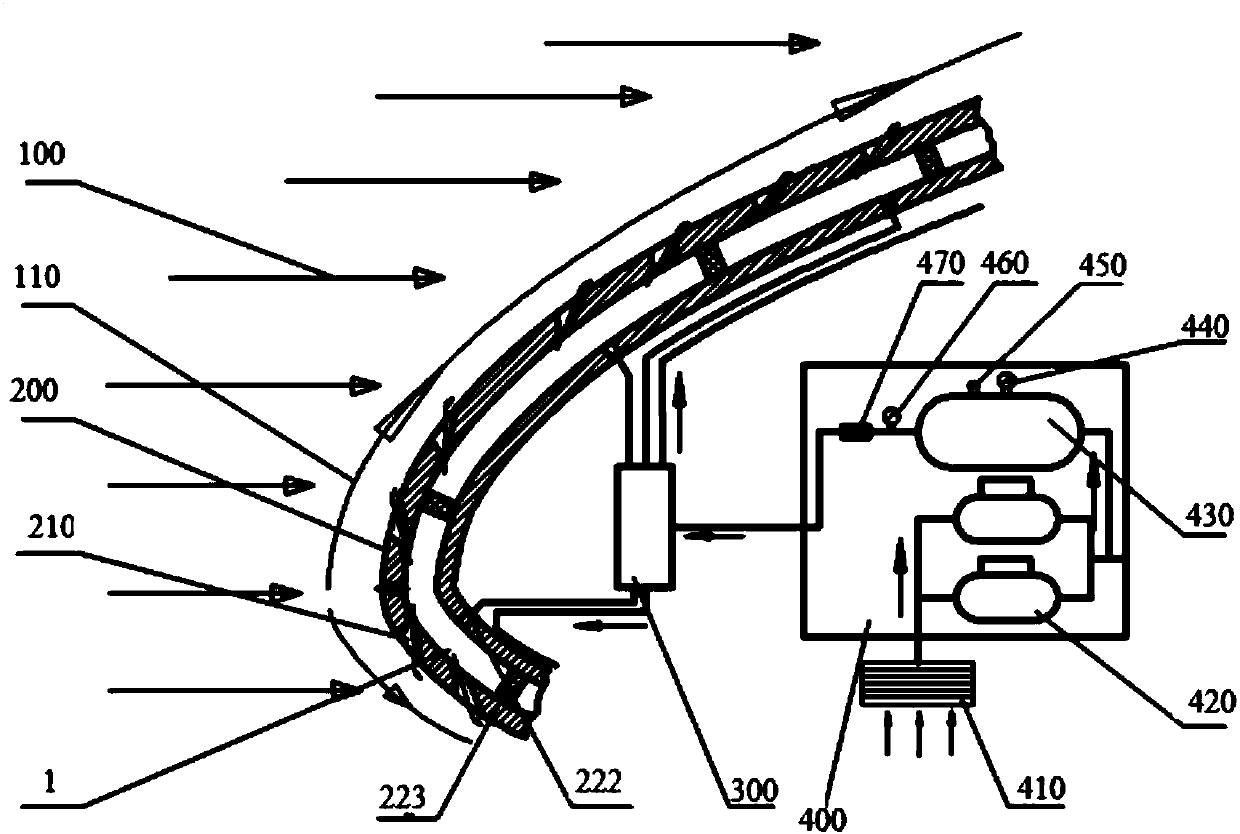

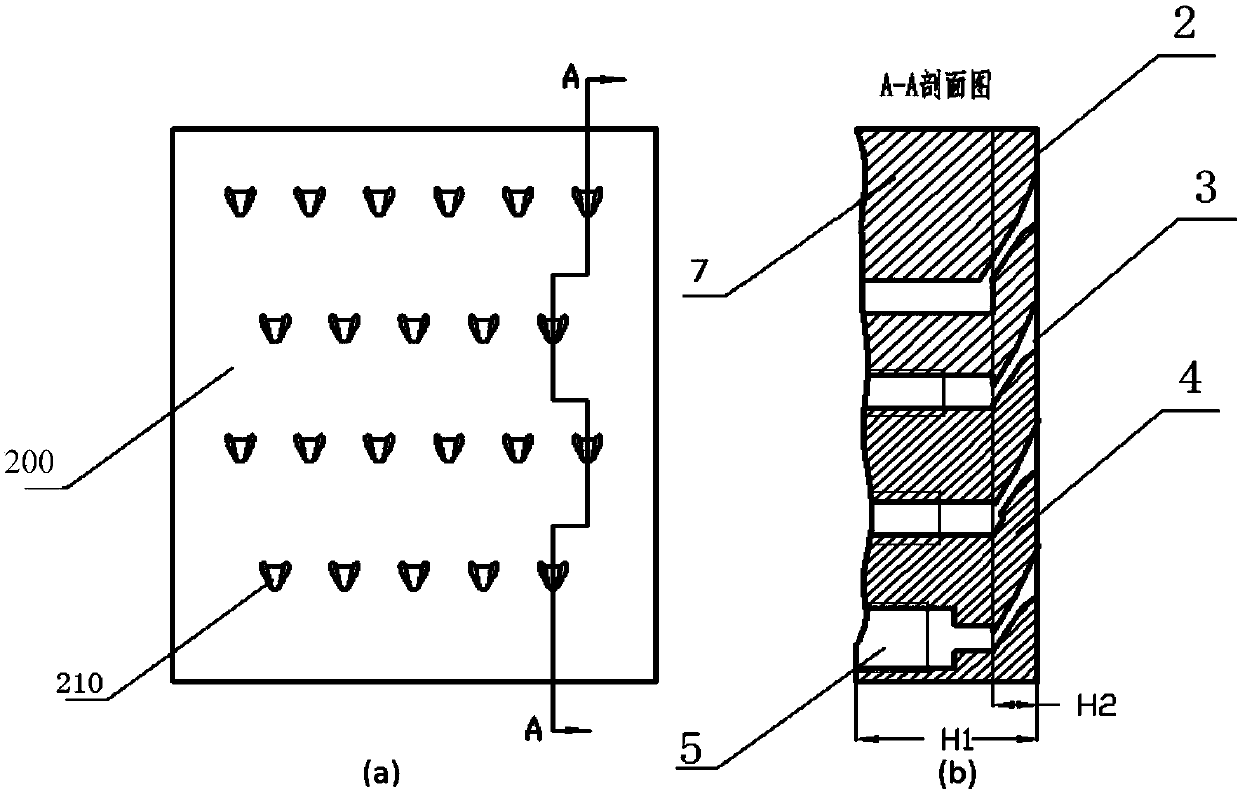

[0063] see figure 1 , the present invention provides an air film drag reduction syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com