Anti-yellowing matte odorless PU polyurethane top-coat paint and preparation method thereof

A technology of anti-yellowing and polyurethane, which is applied in the field of coatings, can solve the problems of residual gloss and odor, difficult gloss, poor yellowing resistance, etc., and achieve the effect of fast drying speed, delicate and smooth hand feeling, and better leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a kind of preparation method of anti-yellowing dull PU polyurethane clear topcoat, comprising the following steps:

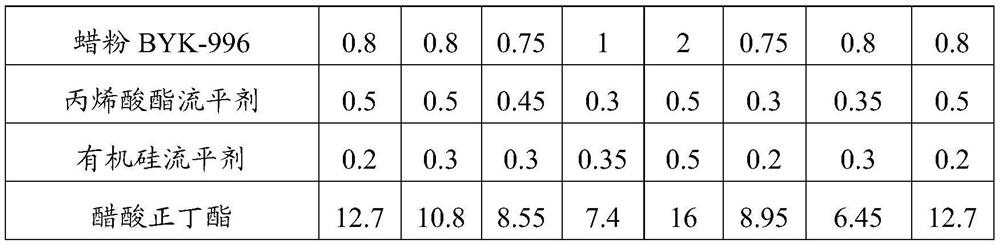

[0042] Step 1. Mix anti-yellowing acrylic resin, cellulose acetate butyrate, ether ester solvent, dispersant and defoamer, and disperse evenly under the condition of 600-800r / min; then add matting powder and wax powder, Disperse under the condition of 800-1200r / min until the fineness is ≤30um; then add acrylic leveling agent, silicone leveling agent and ester solvent, disperse evenly under the condition of 600-800r / min, and then pass the inspection. Filtration and packaging to obtain component A;

[0043] Step 2. Add dehydrating agent to n-butyl acetate, add HDI isocyanate curing agent and TDI isocyanate curing agent in turn after 24 hours, stir evenly, and then inspect and pack to obtain component B;

[0044] Step 3, mixing propylene glycol methyl ether acetate, n-butyl acetate and ethyl acetate and stirring evenly, then i...

Embodiment 1

[0061] The anti-yellowing matt odor-cleaning PU polyurethane clear topcoat consists of component A, component B and diluent; the component A is A, the component B is BA, and the diluent is dilute a.

Embodiment 2

[0063] The anti-yellowing matt odor-cleaning PU polyurethane clear topcoat is composed of component A, component B and diluent; the component A is AB, the component B is BB, and the diluent is dilute b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com