Rapid regeneration method of positive electrode material of waste ternary lithium ion battery

A lithium-ion battery and cathode material technology, applied in the field of rapid regeneration of waste ternary lithium-ion battery cathode materials, can solve problems such as unattractive economics, long processing cycle, complicated operation, etc., and achieve huge industrial application potential and operation Simple, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

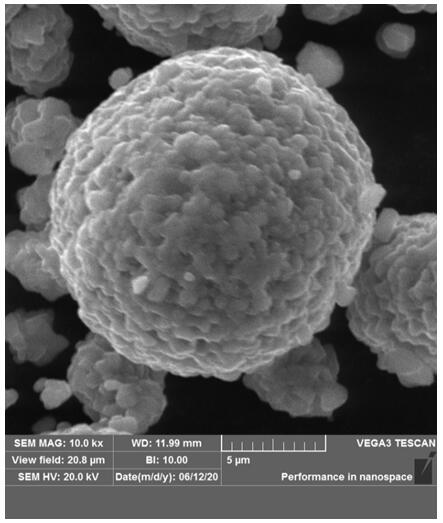

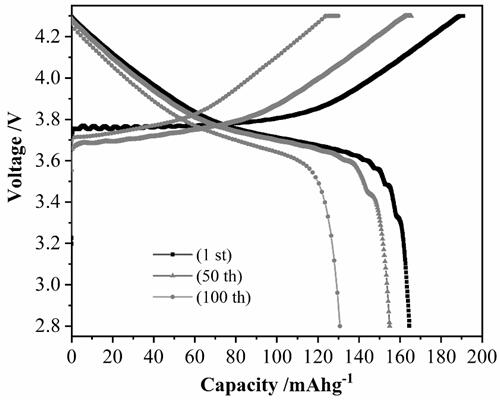

[0032] A method for oxidation repair and quick regeneration of a waste ternary lithium-ion battery positive electrode material, the specific steps are as follows:

[0033] (1) Replace the waste NCM622 (LiNi 0.6 co 0.2 mn 0.2 o 2 ) The ternary lithium-ion battery is deeply discharged in a sodium chloride solution with a concentration of 2mol / L, and the discharge time is 72h. The battery is manually disassembled, and the positive electrode, negative electrode copper foil, casing, diaphragm, etc. are separated;

[0034] (2) Clean the positive plate with dimethyl carbonate, then place it in NMP with a solid-to-liquid ratio of 100g / L, and add ultrasonic treatment for 30 minutes to obtain a suspension containing waste ternary powder;

[0035] (3) Put the suspension obtained in step (2) into a centrifuge tube and centrifuge at 1000rpm for 30min. After the centrifugation is completed, pour off the supernatant, and then perform centrifugation again, repeating 2 times;

[0036] (4) ...

Embodiment 2

[0043] A method for oxidation repair and quick regeneration of a waste ternary lithium-ion battery positive electrode material, the specific steps are as follows:

[0044] (1) Replace the waste NCM523 (LiNi 0.5 co 0.2 mn 0.3 o 2 ) The ternary lithium-ion battery is deeply discharged in a 3mol / L sodium chloride solution, and the discharge time is 24h. The battery is manually disassembled, and the positive electrode, negative electrode copper foil, shell, diaphragm, etc. are separated;

[0045](2) Clean the positive plate with dimethyl carbonate, then place it in NMP with a solid-to-liquid ratio of 100g / L, and add ultrasonic treatment for 20 minutes to obtain a suspension containing waste ternary powder;

[0046] (3) Put the suspension obtained in step (2) into a centrifuge tube and centrifuge at 1300 rpm for 25 minutes. After the centrifugation is completed, discard the supernatant, and then perform centrifugation again, repeating 3 times;

[0047] (4) Dry the centrifuged s...

Embodiment 3

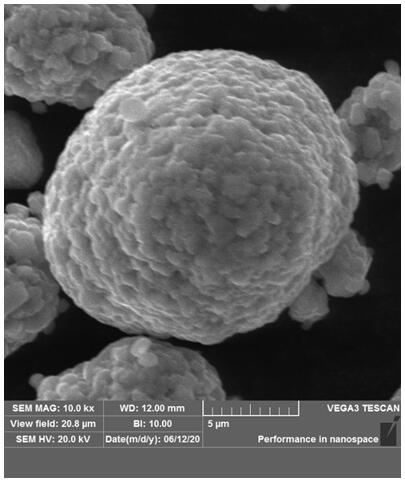

[0055] A method for oxidation repair and quick regeneration of a waste ternary lithium-ion battery positive electrode material, the specific steps are as follows:

[0056] (1) Replace the used NCM811 (LiNi 0.8 co 0.1 mn 0.1 o 2 ) The ternary lithium-ion battery is deeply discharged in 1mol / L sodium chloride solution, and the discharge time is 60h. The battery is disassembled manually, and the positive electrode sheet, negative electrode copper foil, shell, diaphragm, etc. are separated;

[0057] (2) Clean the positive plate with dimethyl carbonate, then place it in NMP with a solid-to-liquid ratio of 100g / L, and add ultrasonic treatment for 40 minutes to obtain a suspension containing waste ternary powder;

[0058] (3) Put the suspension obtained in step (2) into a centrifuge tube and centrifuge at 1500rpm for 20min. After the centrifugation is completed, discard the supernatant, and then perform centrifugation again, repeating 2 times;

[0059] (4) Dry the centrifuged sus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com