Fixed-point cutting device for wood-plastic composite board production

A composite board and fixed-point technology, which is applied to plywood presses, irregular removal devices, wood compression, etc., can solve the problems of large labor demand, burrs on the cut surface, and difficult cutting, so as to improve safety and cut off The effect of leveling the surface and reducing the amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

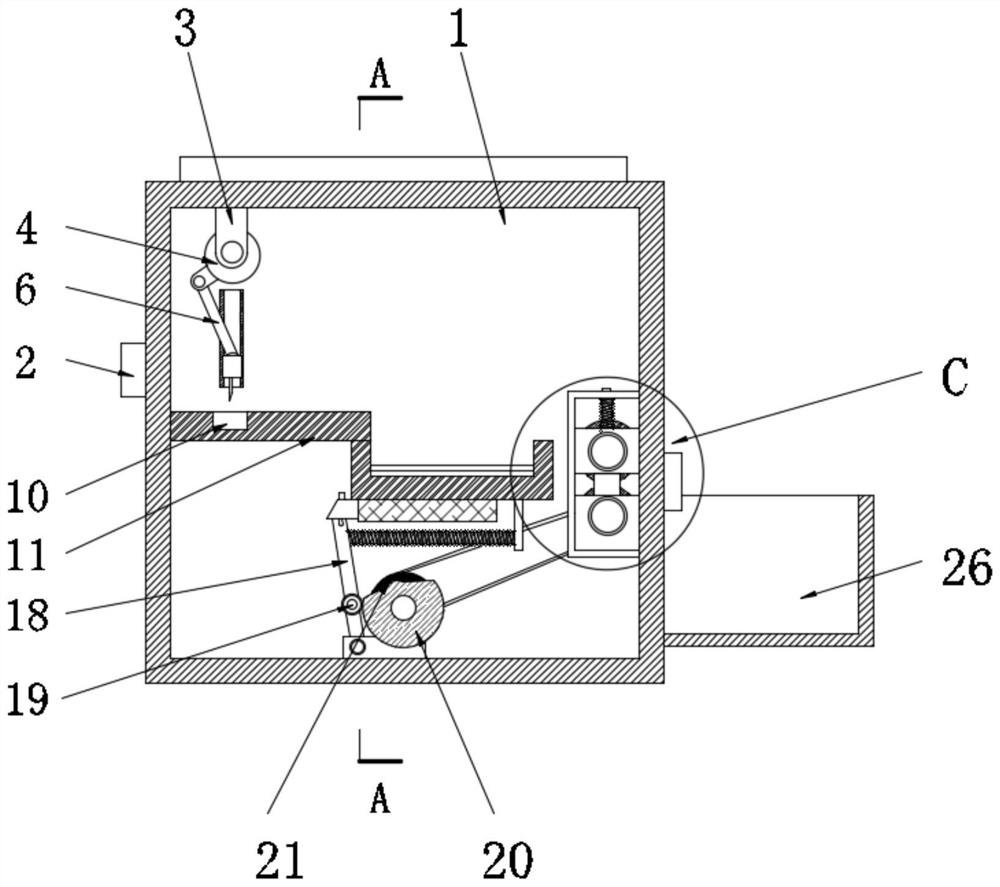

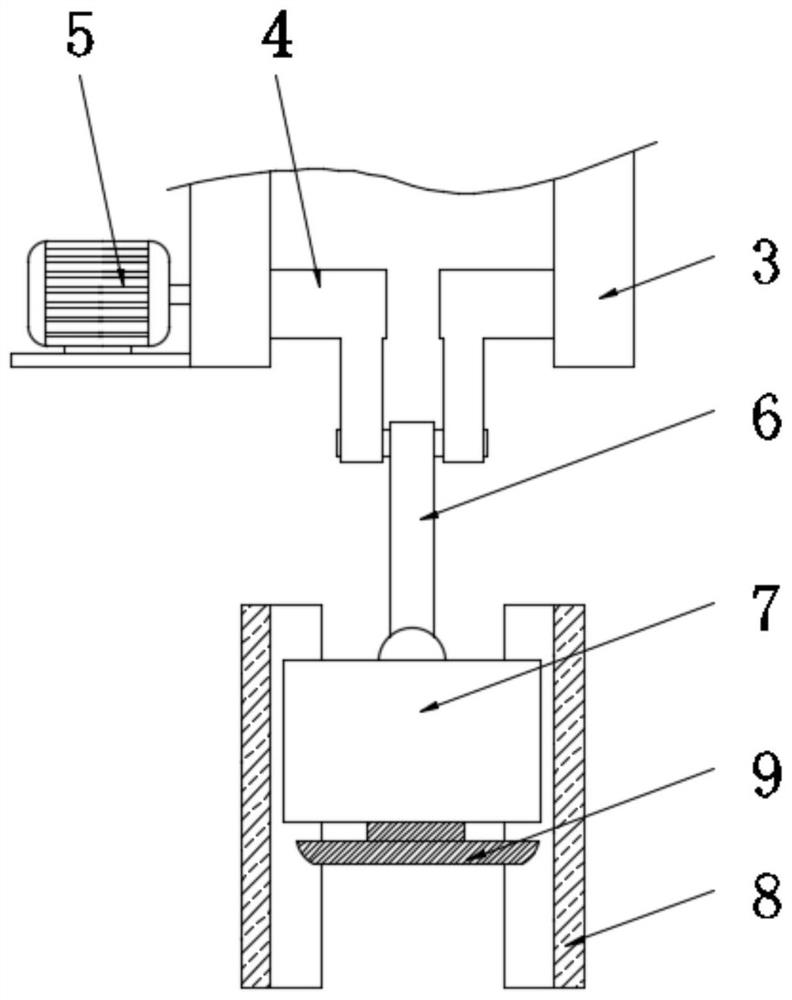

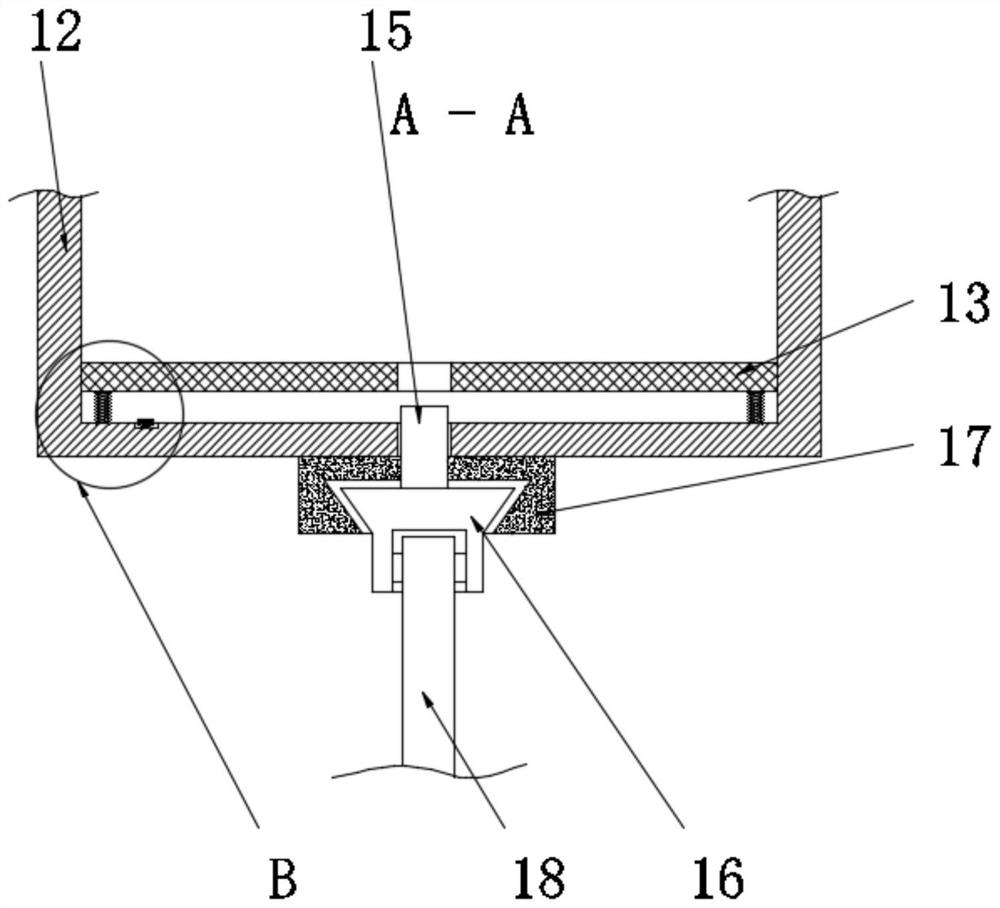

[0021] The invention provides a fixed-point cutting device for wood-plastic composite board production, as attached figure 1 to attach Figure 5 Shown: including the processing chamber 1, the left and right sides of the processing chamber 1 are provided with inlet and outlet ports 2, and the inside of the processing chamber 1 is fixedly installed with a bearing seat 3, and the inner rotation of the bearing seat 3 is installed with a connecting plate 4, connected The outer side of the plate 4 is fixedly installed with the first motor 5, and the transmission rod 6 is installed in rotation between the adjacent connecting plates 4, and the bottom end of the transmission rod 6 is movably installed with a moving seat 7, and the transmission rod 6 is composed of an upper cylinder and a lower ball. , the moving seat 7 is slidably installed inside the guide rail 8, and the lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com