A kind of waste steel slag recovery processing equipment

A waste steel slag recycling technology, applied in solid separation, chemical instruments and methods, grids, etc., can solve the problem that the waste steel slag recycling equipment does not have an auxiliary feeding structure, reduce the functionality of the waste steel slag recycling equipment, and reduce waste. The stability of steel slag recycling and processing equipment has been improved to achieve the effect of improving flexibility, smooth mobile operation, and convenient adjustment operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Next, the technical solutions in the embodiments of the present invention will be described in conjunction with the embodiment of the present invention. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained in the preparation of creative labor.

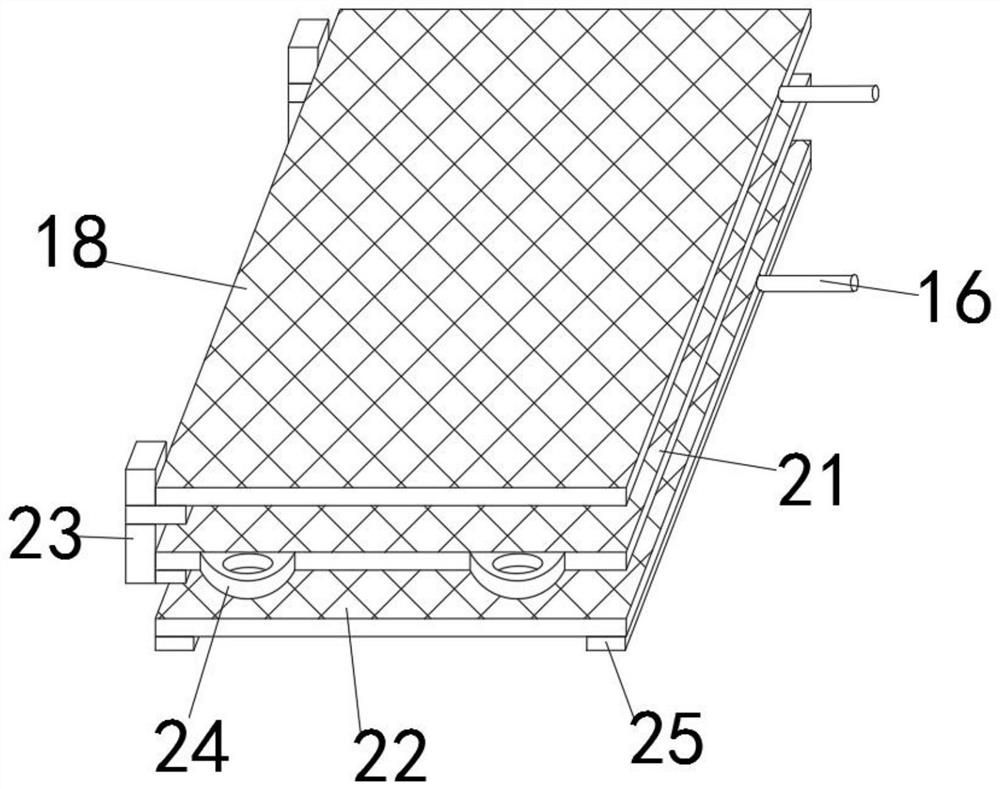

[0034] like Figure 1-7 As shown in a slag waste recycling apparatus, comprising a fixed chassis 4, vibration sieve frame 3 and the hopper 7, vibration bracket 3 removably attached to the upper portion of the fixed chassis, the screen 7 of tank 4 is fixedly mounted on the vibrating frame 3 the upper end of the inside of the inner screen tank 7 is attached to the first screen 18 is fixed, the inner screen adjacent a lower portion of hopper 7 is fixed to the first screen 18 second screen 21 is mounted, and the outer end 21 of the second screen two fixing surface is fixedly mounted hanging ring 24, the sieve and hopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com