Tea polyphenol blanking opening

A technology of tea polyphenols and material inlet, which is applied in the field of tea polysaccharide preparation, and can solve problems such as bridging, melting and coking, and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

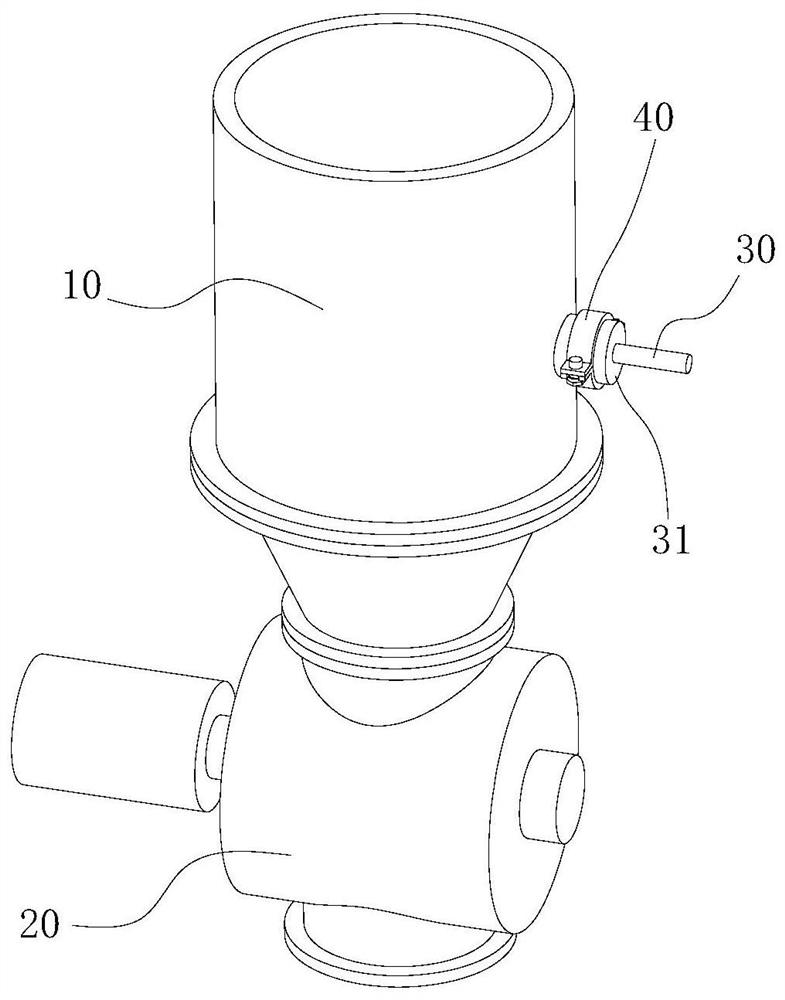

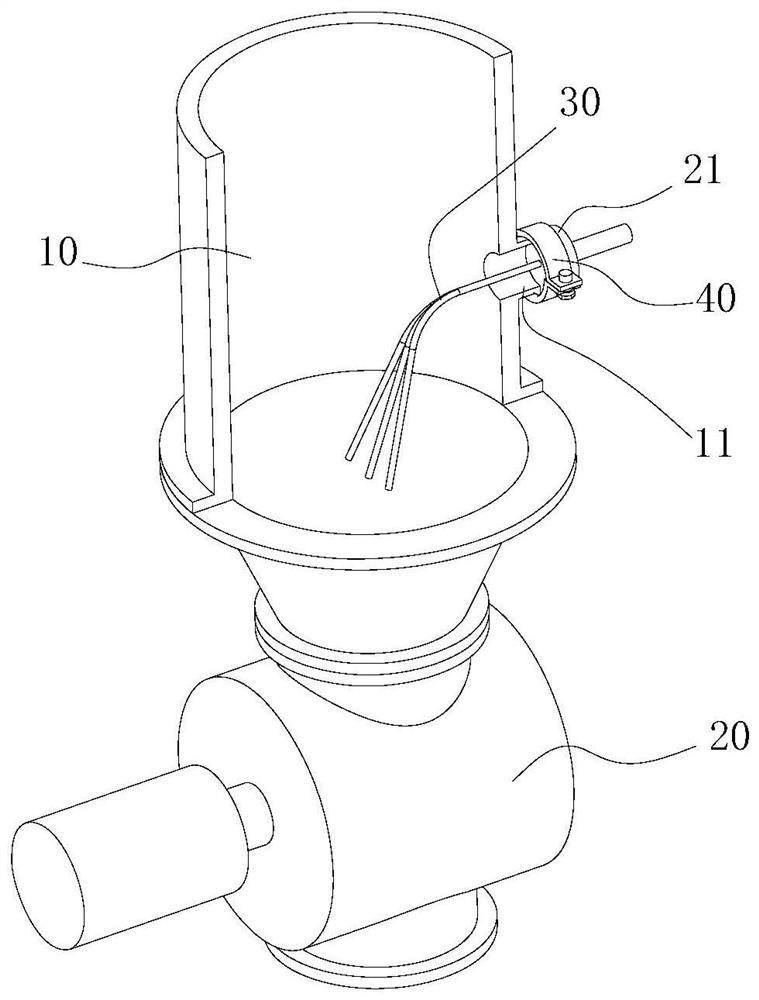

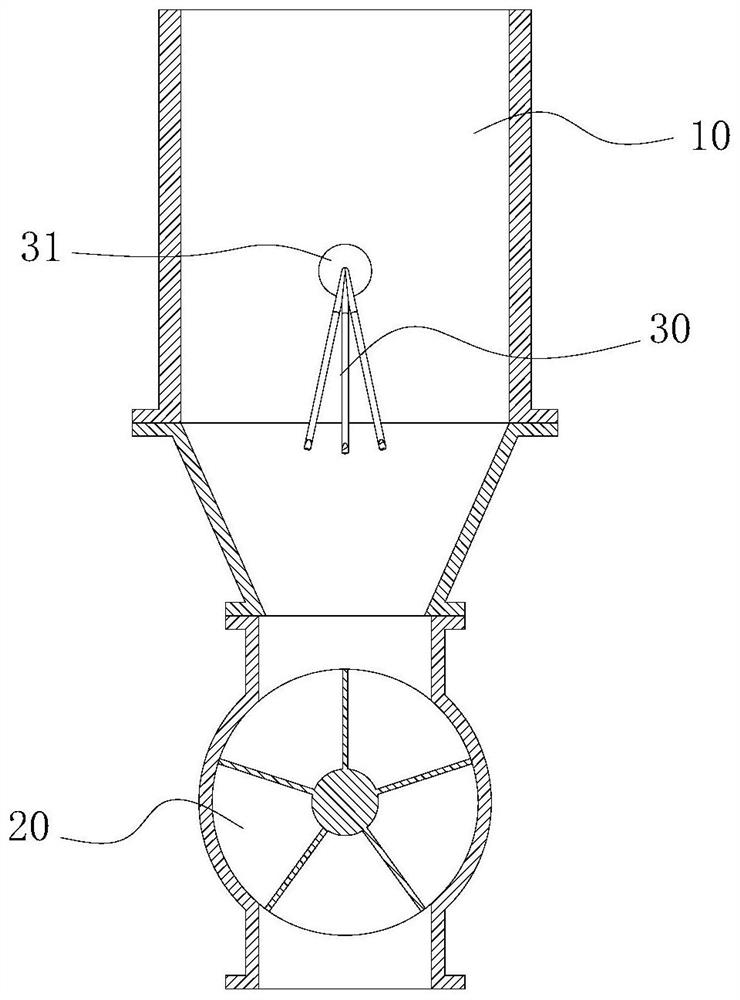

[0010] A tea polyphenol discharge port, comprising a cyclone 10 for separating tea polyphenols, the lower end of the cyclone 10 is provided with a discharge valve 20, and the cyclone 10 is provided with an air pipe blowing to the discharge valve 20 30.

[0011] The above-mentioned solution can also be used for the feeding port of other sugar preparations. By blowing airflow into the cyclone 10, the temperature of the tea polysaccharide can be effectively reduced to avoid its melting and coking. The blocking material of the bridge is blown away so that the tea polyphenols can pass through the discharge valve 20 smoothly.

[0012] The air pipe 30 passes through the air pipe seat 31 and is fixedly connected thereto. The air pipe seat 31 forms a detachable fit with the side pipe 11 provided on the cyclone 10 and communicates with the inside and outside of the cyclone 10 . The trachea 30 outside the trachea seat 31 is connected to the air supply device, so that the trachea 30 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com