Moisturizing emulsion based on ginseng polysaccharide and preparation method thereof

A moisturizing lotion and ginseng polysaccharide technology, which is applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the consumption needs of single moisturizing lotion, increase the irritation of cosmetics, and be prone to phase transitions. , to meet the needs of the market, moisturizing and emollient effect, increase the stability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

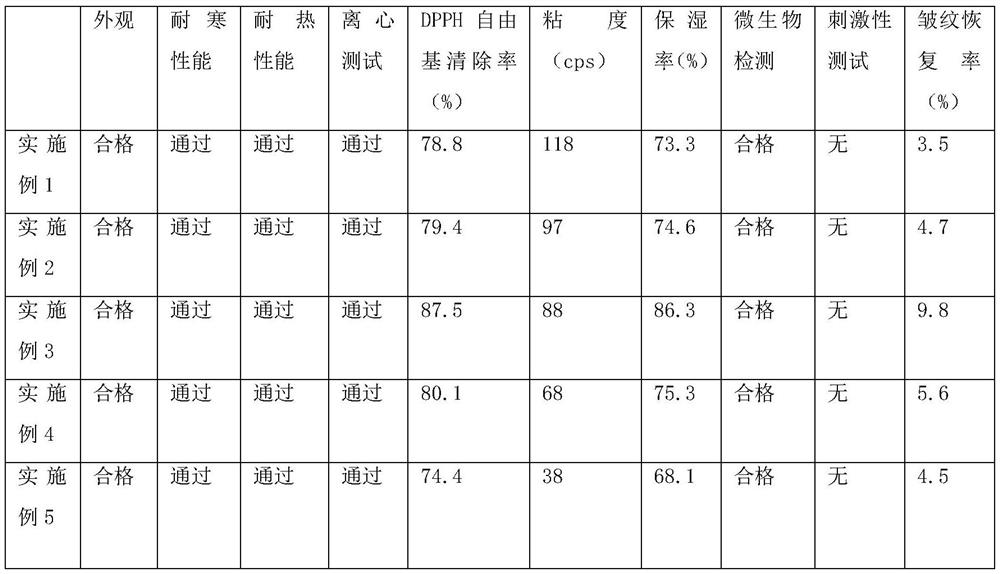

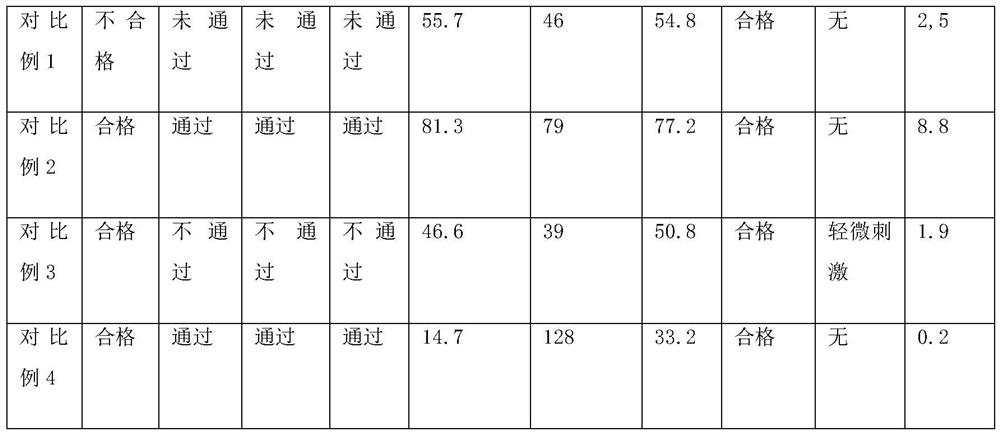

Examples

Embodiment 1

[0036] S1. Mix Tween 40 and sucrose stearate, and stir at 200r / min for 10min to obtain a surfactant;

[0037] S2. Mix vegetable oil, glycerin, propylene glycol, and tocopheryl acetate, and stir at a high speed of 1500r / min for 10min to obtain an oily compound;

[0038] S3. Under the temperature condition of 75° C., put the gellan gum in deionized water and stir for 25 minutes, and cool to 45° C. to obtain a gellan gum solution;

[0039] S4. At a constant temperature of 45°C, mix the surfactant and the oily compound into deionized water, stir at high speed for 10 minutes, add ginseng polysaccharides and preservatives, add gellan gum solution and water-locking magnet while stirring, and Stir at a high speed of 1500r / min for 15min, stand still at 36°C for 18h, and vacuum foam to obtain the finished moisturizing lotion.

[0040] 10 parts of surfactant, 20 parts of oily compound, 30 parts of gellan gum, 15 parts of ginseng polysaccharide, 15 parts of water-locking magnet, 0.2 part...

Embodiment 2

[0043] S1. Mix Tween 40 and sucrose stearate, and stir at 225r / min for 13min to obtain a surfactant;

[0044] S2. Mix vegetable oil, glycerin, propylene glycol, and tocopheryl acetate, and stir at a high speed of 1650r / min for 17min to obtain an oily compound;

[0045] S3. Under the temperature condition of 80° C., put the gellan gum in deionized water and stir for 27 minutes, and cool to 47° C. to obtain a gellan gum solution;

[0046] S4. At a constant temperature of 47°C, mix the surfactant and the oily compound into deionized water, stir at high speed for 15 minutes, add ginseng polysaccharides and preservatives, add gellan gum solution and water-locking magnet while stirring, to Stir at a high speed of 1650r / min for 25min, stand still at 36°C for 18h, and vacuum foam to obtain the finished moisturizing lotion.

[0047] 11 parts of surfactant, 23 parts of oily compound, 33 parts of gellan gum, 17 parts of ginseng polysaccharide, 16 parts of water-locking magnet, 0.3 part ...

Embodiment 3

[0050] S1. Mix Tween 40 and sucrose stearate, and stir at 250r / min for 15min to obtain a surfactant;

[0051] S2. Mix vegetable oil, glycerin, propylene glycol, and tocopheryl acetate, and stir at a high speed of 1750r / min for 20min to obtain an oily compound;

[0052] S3. Under the temperature condition of 85° C., put the gellan gum in deionized water and stir for 30 minutes, and cool to 40° C. to obtain a gellan gum solution;

[0053] S4. At a constant temperature of 50°C, mix surfactants and oily compounds into deionized water, stir at high speed for 20 minutes, add ginseng polysaccharides and preservatives, add gellan gum solution and water-locking magnet while stirring, to Stir at a high speed of 1750r / min for 30min, stand at a temperature of 37°C for 19h, and vacuum foam to obtain a finished moisturizing lotion.

[0054] 12 parts of surfactant, 25 parts of oily compound, 35 parts of gellan gum, 20 parts of ginseng polysaccharide, 17 parts of water-locking magnet, 0.4 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com