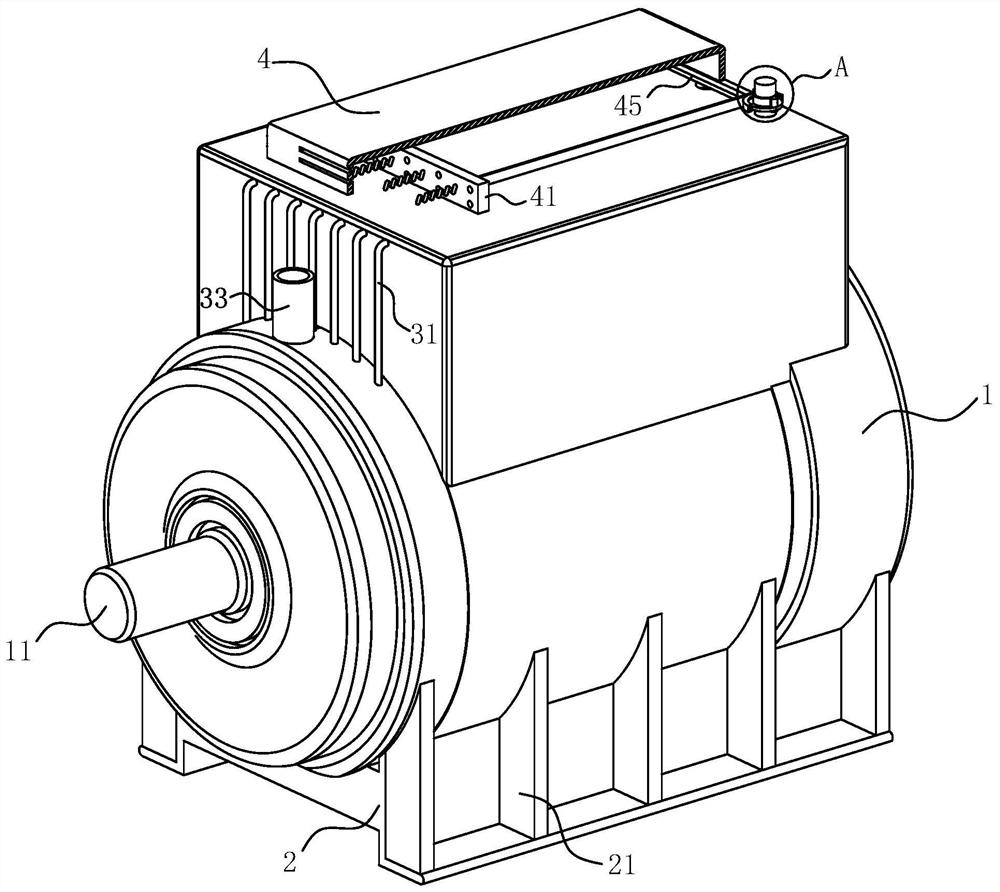

3300V high-voltage permanent magnet variable frequency motor all-in-one machine

A variable frequency motor and integrated machine technology, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve problems such as troublesome use and excessive accumulation of motor dust, reduce the steps of water cooling and heat dissipation, enhance heat conduction, and simplify the structure of water cooling and heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

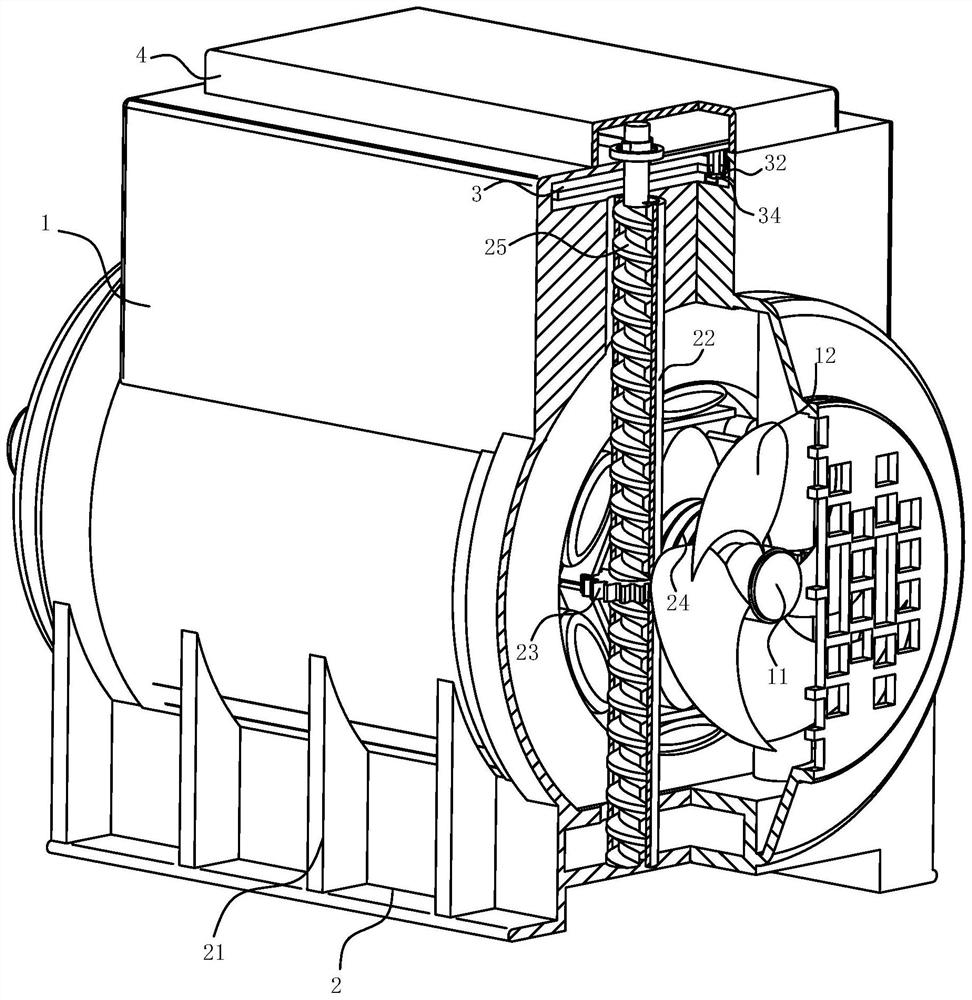

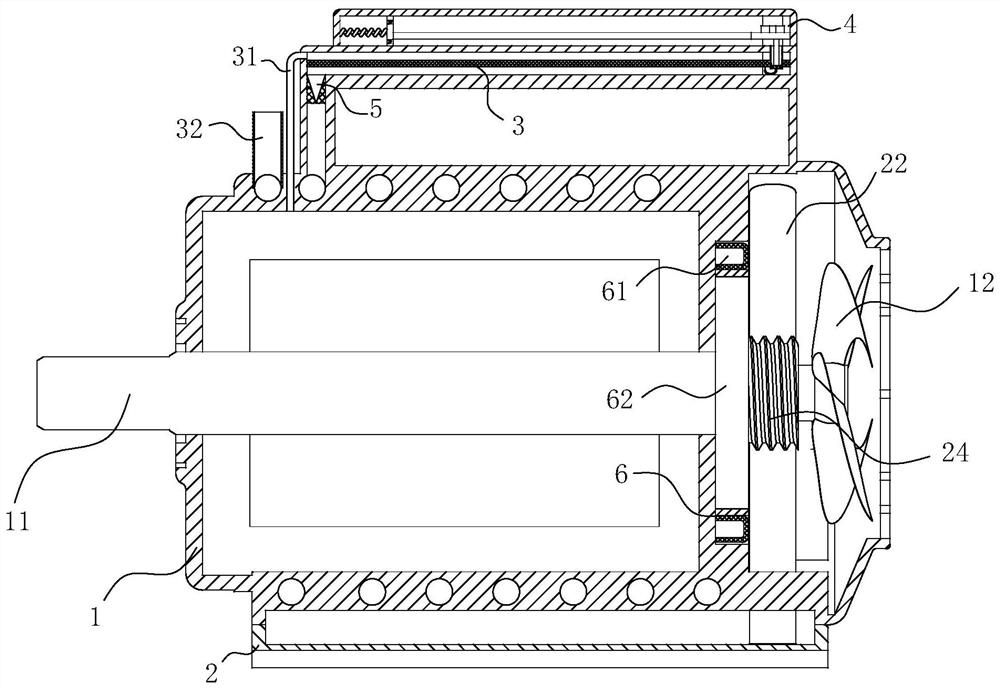

[0026] As an embodiment of the present invention, the air box 4 is fixedly connected to the top of the body; the air intake pipe 32 is designed to be located in the air box 4 at one end away from the casing 1; Pressing plate 41; said inflatable box 4 is designed with an opening close to the side of the extruding plate 41; said extruding plate 41 is provided with evenly distributed one-way through holes; Two through grooves; the second through groove and the first through groove conduction design; the second through groove is rotationally connected with a rotating shaft 42; the rotating shaft 42 is fixedly connected with the screw column 25; the rotating shaft 42 One end of the inflatable box 4 is sleeved with a toggle wheel 43; the toggle wheel 43 is designed in a "ten" shape; the outer side of the toggle wheel 43 is sleeved with a turning wheel 44; the turning wheel 44 and the toggle wheel 43 meshing design; the side of the rotating wheel 44 close to the extrusion plate 41 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com