Heterogeneous solution gas content detection device and detection method

A detection device and gas holdup technology, which is applied in the processing of detection response signals, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze fluids, etc., can solve the problems of in-situ real-time detection of gas holdup, inability to measure bubble behavior, and low sensitivity. , to achieve the effect of improving convenience, avoiding defects and deficiencies, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for detecting the gas holdup of a heterogeneous solution using the above-mentioned device, comprising the steps of:

[0031] (1) Background parameter setting:

[0032] According to the material of the liquid container to be tested, the wall thickness of the liquid container to be tested, the density of the liquid to be tested, and the temperature of the liquid to be tested are set through the data signal processor 4; the corresponding program for data input can be written by the programmers of the software company Finish.

[0033] (2) Detection benchmark setting:

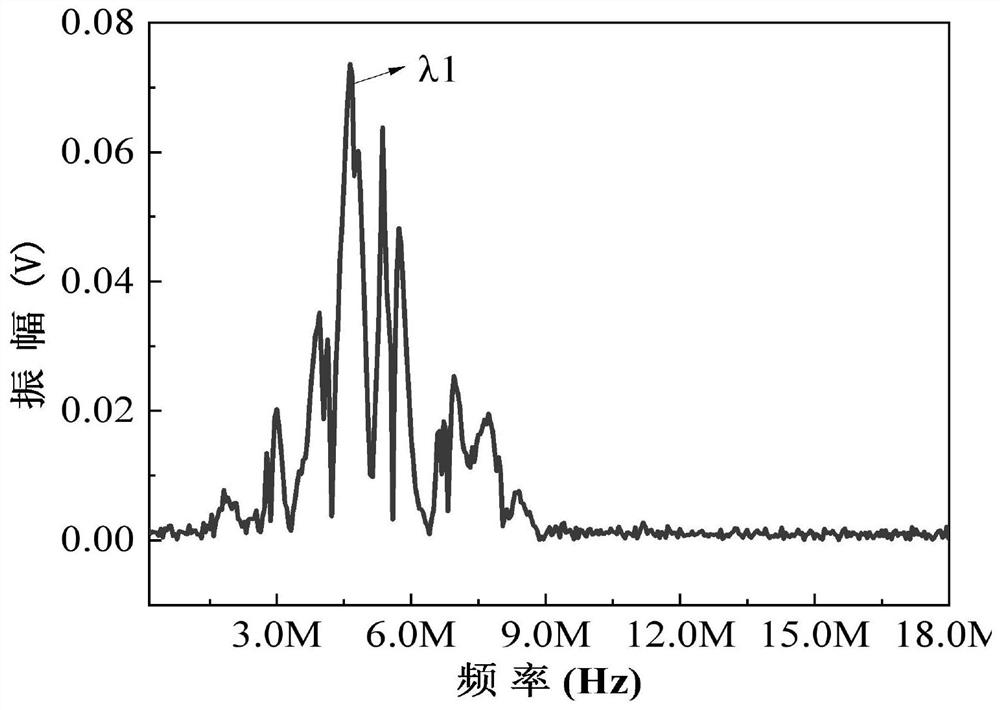

[0034] Fill the container of the liquid to be tested with the liquid to be tested that has been completely degassed, and carry out ultrasonic detection through the above-mentioned device, and the feedback ultrasonic image obtained by the detection ( figure 1 ) to record, and record the ultrasonic amplitude as λ1;

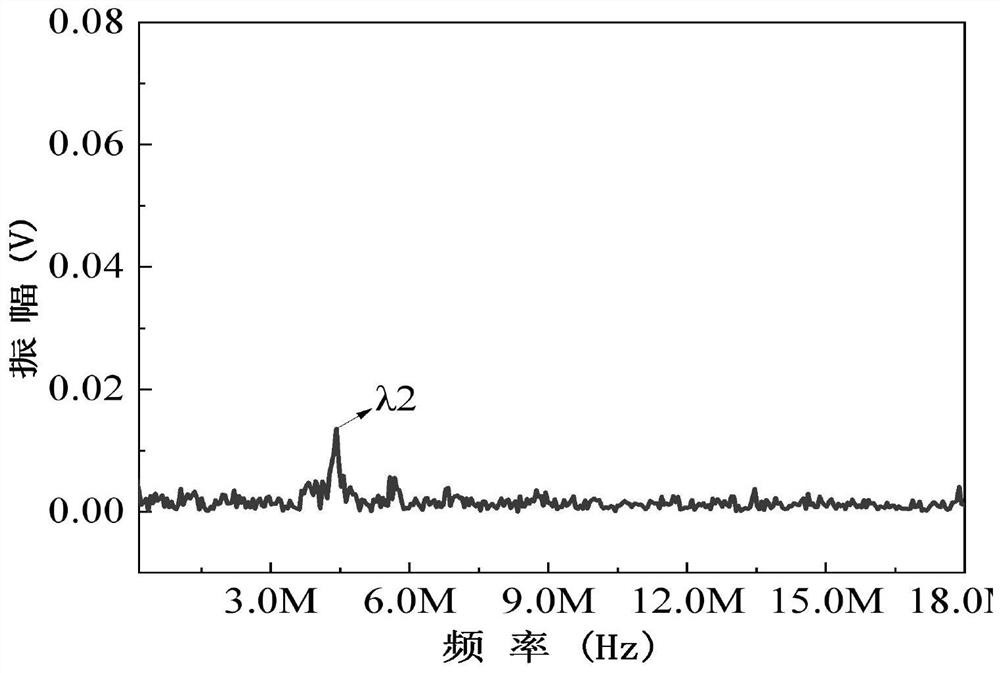

[0035] Fill the container of the liquid to be tested with the liquid to be tested t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com