Low-thermal-conductivity brick for rotary cement kiln and production and manufacturing method of low-thermal-conductivity brick

A cement rotary kiln, low thermal conductivity technology, applied in the direction of rotary drum furnace, lighting and heating equipment, furnace, etc., can solve the problem of pollution pollution of heat-conducting bricks, etc., to reduce tire wear and cylinder deformation rate, heat insulation effect Good effect of reducing masonry weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

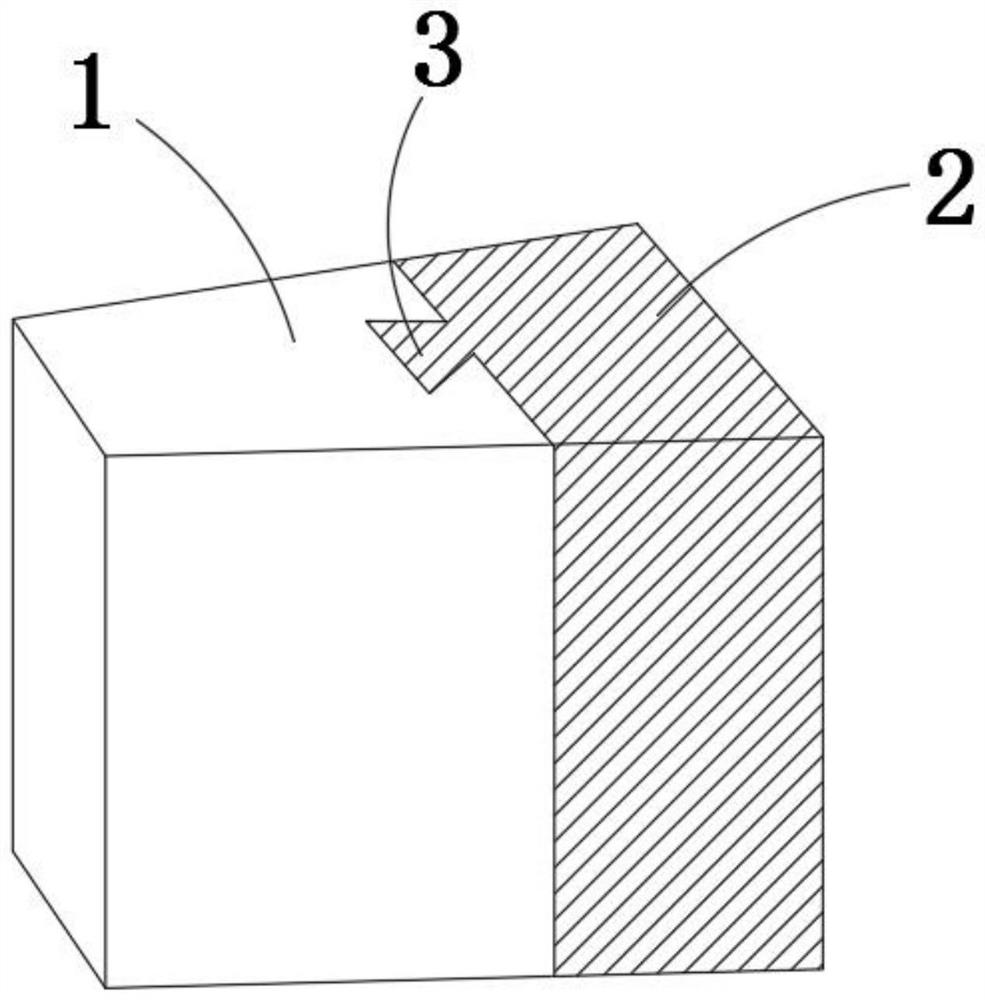

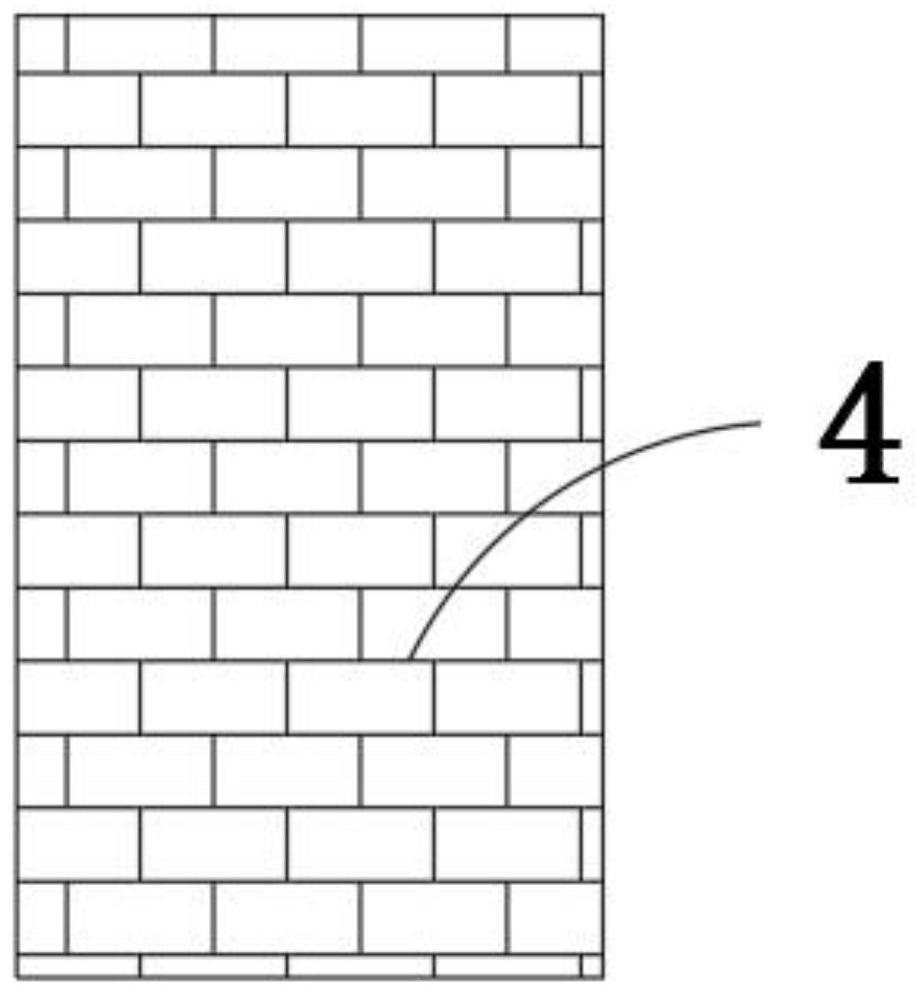

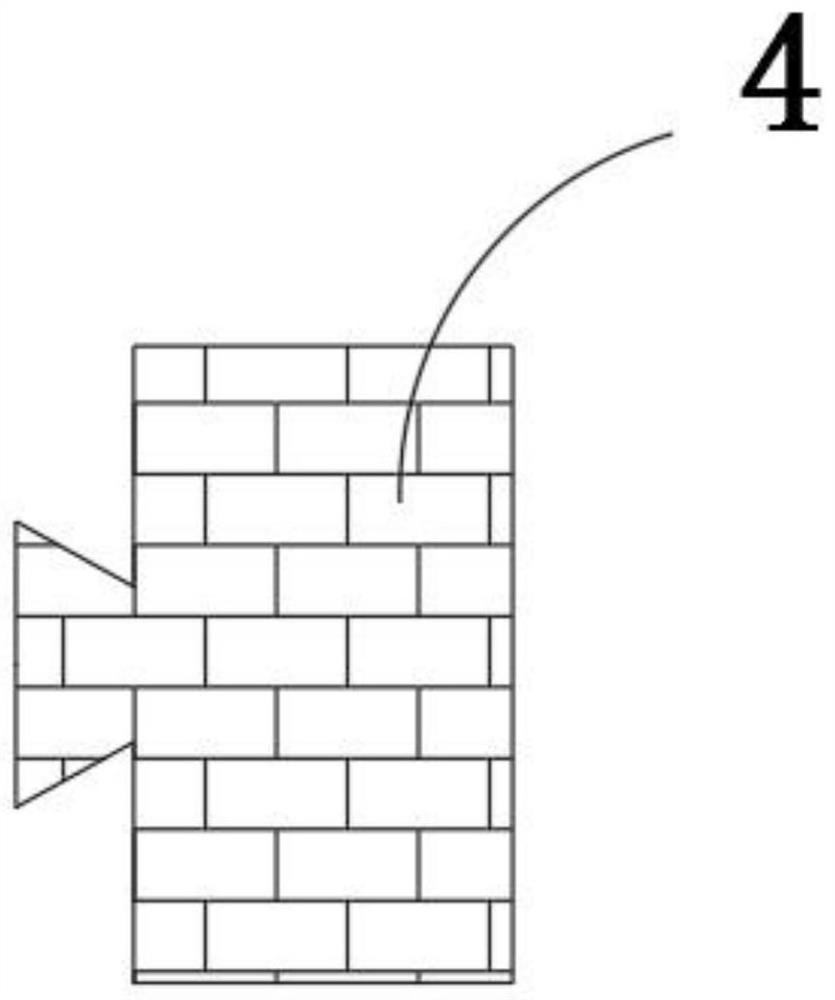

[0027] Such as Figure 1-4 As shown, a low thermal conductivity brick for a cement rotary kiln includes a main refractory brick part 1 and an insulator part 2. The main refractory brick part 1 adopts magnesia with a limit particle size of 5 mm, which is relatively convenient to implement in the field of refractory materials in my country, and magnesia Fused magnesia and sintered magnesia can be selected, with a particle size of 5mm; the particle size of the matrix part is 0.075mm fine powder; at the same time, magnesia-alumina spinel particles can be added, and magnesia-alumina spinel can be sintered magnesia-alumina spinel and fused magnesia Aluminum spinel, the particle size is 3mm, the particle size of the matrix part is 0.075mm fine powder; the fineness of the additive powder is 0.045mm, and the steel mesh 4 of the insulation body part 2 is welded by 304 stainless steel wire with a diameter of 2mm.

[0028] A layer of refractory cotton is placed between the main refractory b...

Embodiment 2

[0038] Such as Figure 1-4 As shown, a low thermal conductivity brick for a cement rotary kiln includes a main refractory brick part 1 and an insulator part 2. The main refractory brick part 1 adopts magnesia with a limit particle size of 5 mm, which is relatively convenient to implement in the field of refractory materials in my country, and magnesia Fused magnesia and sintered magnesia can be selected, with a particle size of 0.088mm; the particle size of the matrix part is 0.045mm fine powder; at the same time, magnesia-alumina spinel particles can be added, and magnesia-alumina spinel can be sintered magnesia-alumina spinel, fused magnesia Magnesium-aluminum spinel with a particle size of 0.088mm, the matrix part with a particle size of 0.045mm fine powder; the additive fine powder with a fineness of 0.025mm, the steel mesh 4 of the insulation part 2 is welded by 304 stainless steel wire with a diameter of 3mm.

[0039] A layer of refractory cotton is placed between the main...

Embodiment 3

[0049] Such as Figure 1-4 As shown, a low thermal conductivity brick for a cement rotary kiln includes a main refractory brick part 1 and an insulator part 2. The main refractory brick part 1 adopts magnesia with a limit particle size of 5 mm, which is relatively convenient to implement in the field of refractory materials in my country, and magnesia Fused magnesia and sintered magnesia can be selected, with a particle size of 3.088mm; the particle size of the matrix part is 0.065mm fine powder; at the same time, magnesia-alumina spinel particles can be added, and magnesia-alumina spinel can be sintered magnesia-alumina spinel, fused magnesia Magnesia-aluminum spinel with a particle size of 2.088mm, the particle size of the matrix part is 0.065mm fine powder; the fineness of the additive powder is 0.035mm, and the steel mesh 4 of the insulation body part 2 is welded by 304 stainless steel wire with a diameter of 2.7mm.

[0050] A layer of refractory cotton is placed between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com