Sealing structure of high-pressure composite container

A composite container and sealing structure technology, which is applied to pressure vessels, container discharge methods, and outer walls of container structures, can solve the problems of loose connection between plastic liners and metal terminals, and reduced sealing performance, so as to protect the environment and ensure Safety and the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail by the following examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations on the technical solutions of the present invention.

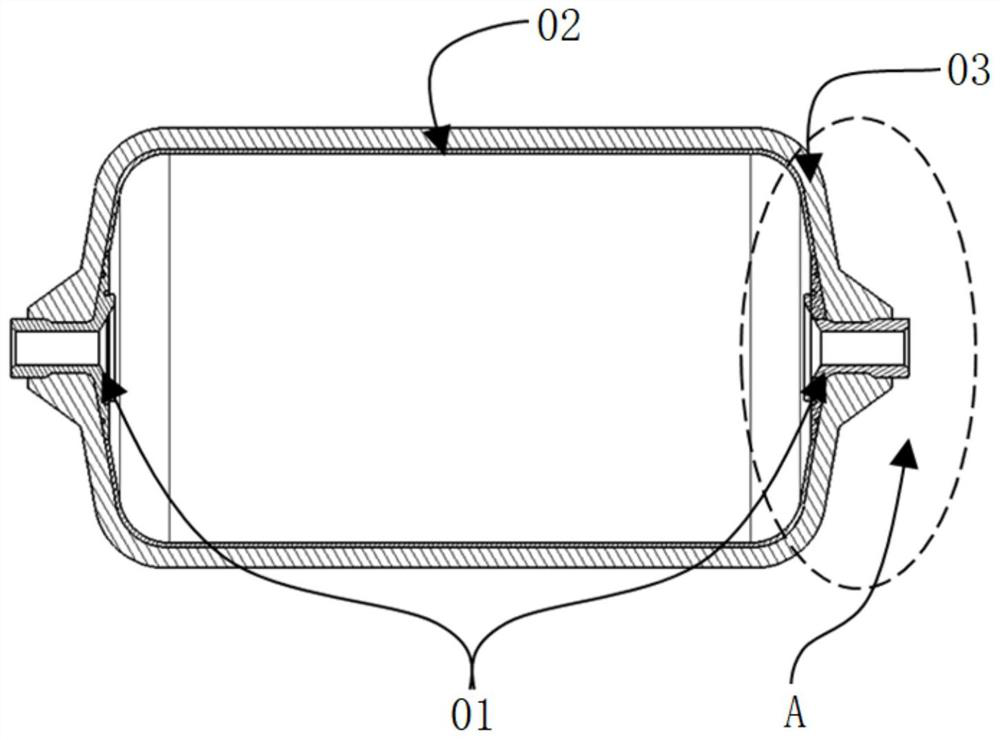

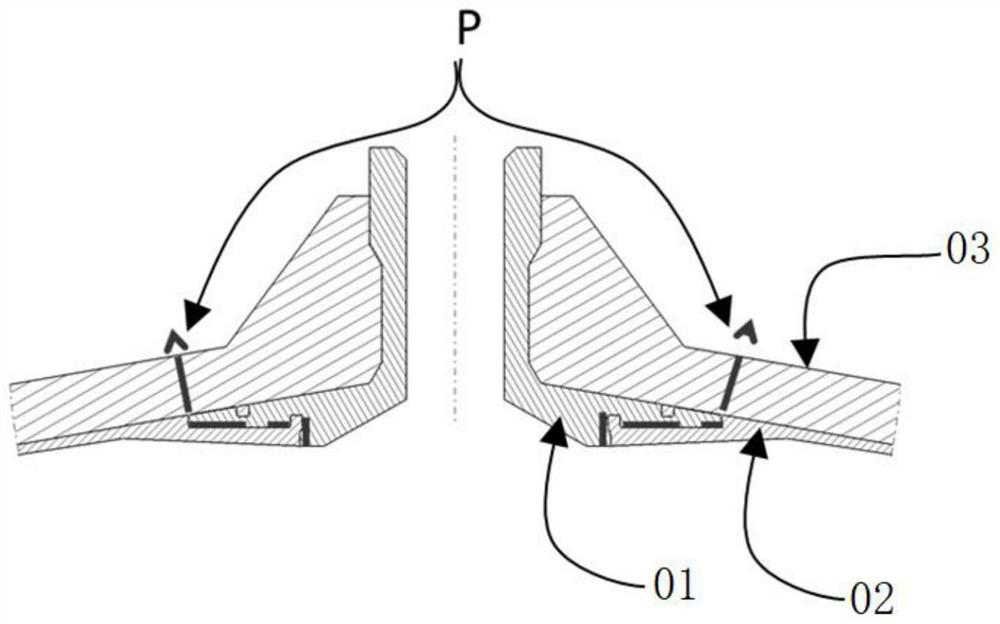

[0027] like image 3 As shown, the present application is a technical solution related to a high-pressure composite container for storing high-pressure gaseous media. The high-pressure composite container 1 includes a plastic inner liner, a filament winding reinforcing layer on the outside of the plastic inner liner, and a bottle mouth with a certain system function. valve etc.

[0028] The type of high-pressure gas used to store high-pressure gas does not need to be limited in this application. All gases that need high-pressure storage can be applied to this high-pressure composite container, such as hydrogen, CNG, helium, nitrogen, etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com