A mining method for thick and large ore bodies

A mining method and thick ore body technology, applied in surface mining, mining equipment, underground mining, etc., can solve the problems of low rock drilling efficiency, high labor intensity, and small stope production, so as to save mining and cutting engineering, High degree of mechanization, realize the effect of ground pressure management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is an example of the thick and large ore body mining method of the present invention, comprising the following steps:

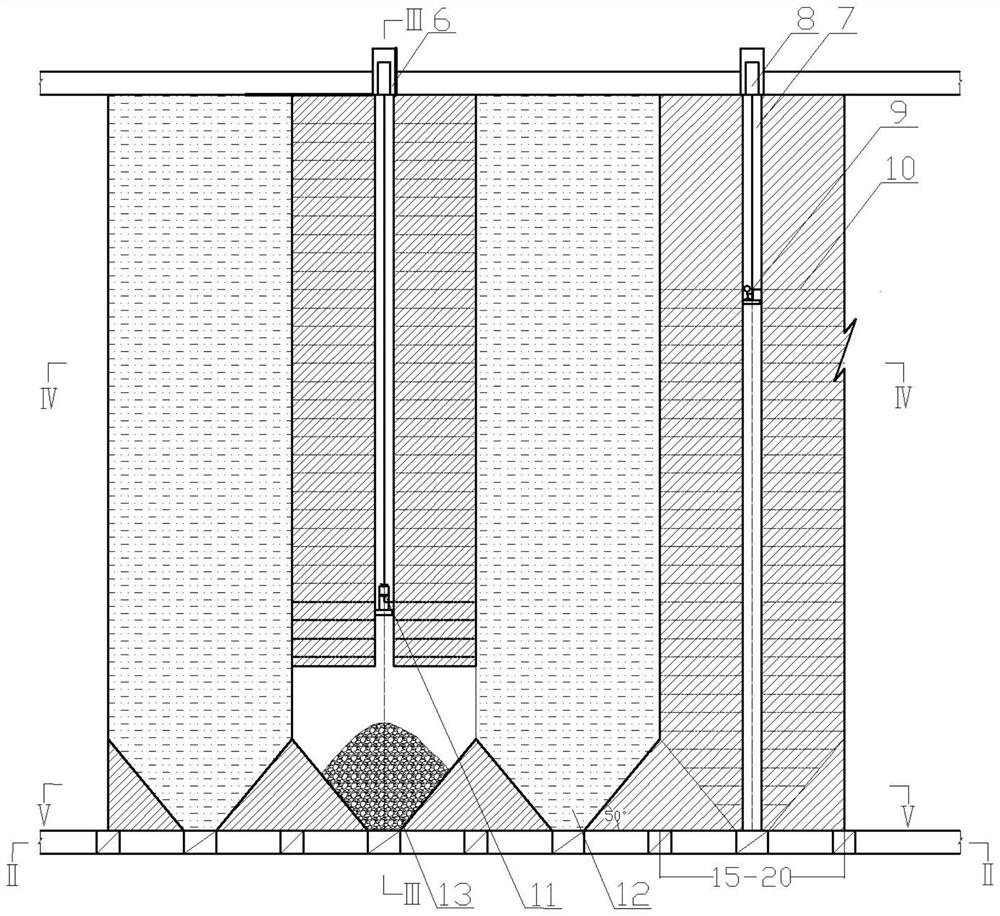

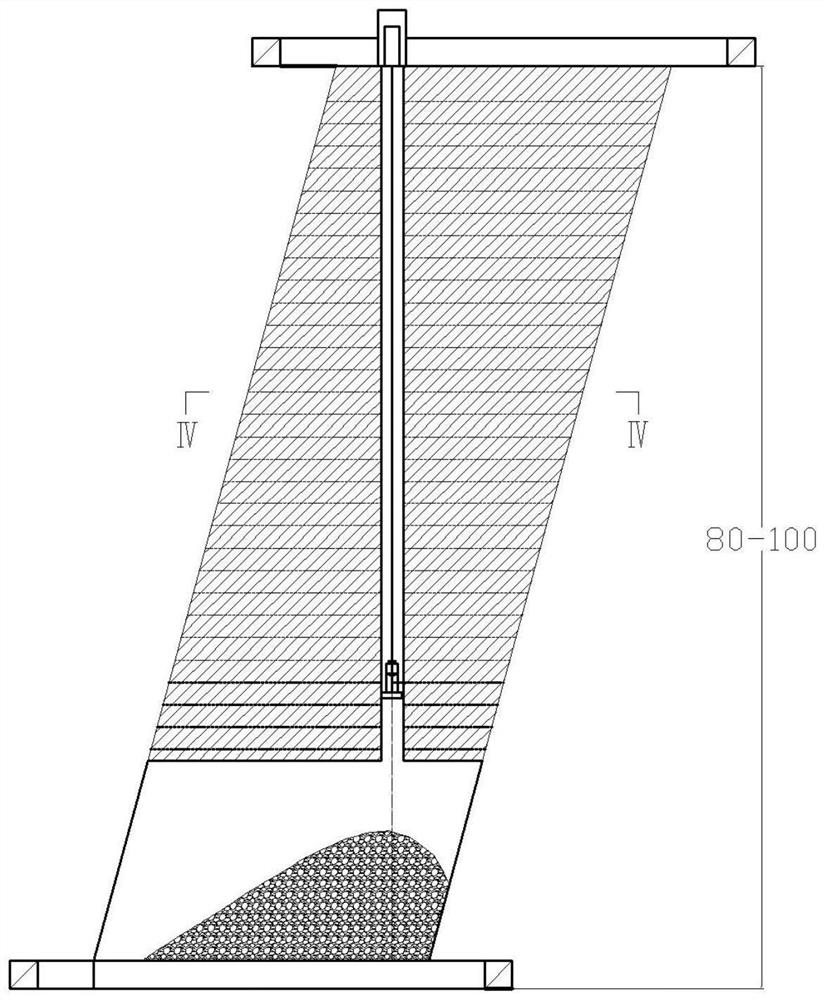

[0034] (1) The stope is arranged perpendicular to the strike of the ore body, and is divided into a one-step stope and a two-step stope. The width of the stope is 15-20m, and the length is the thickness of the ore body; the stage height is 80-100m.

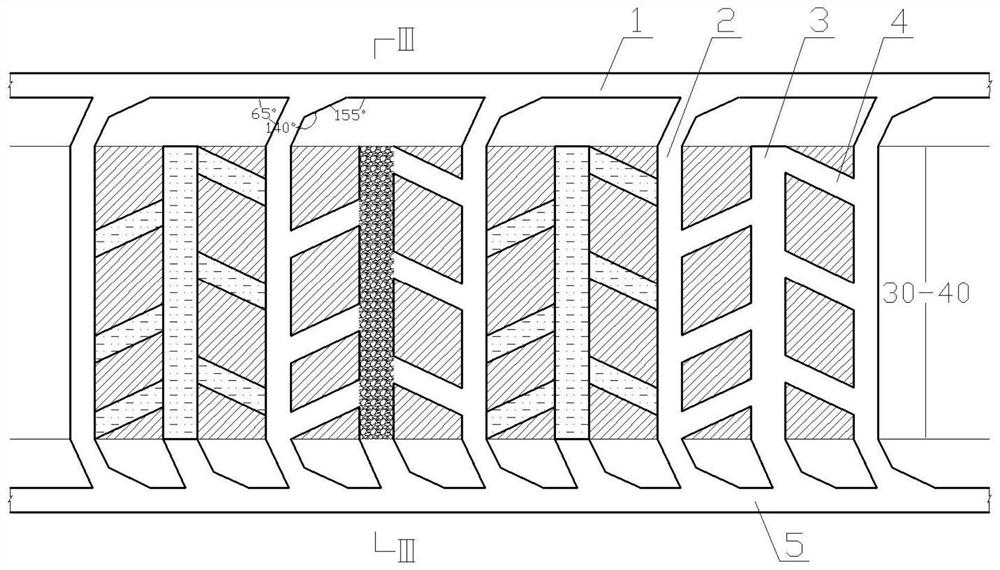

[0035] (2) In the surrounding rock of the upper and lower walls at a distance of 10-15m from the ore body, the out-of-vein transport roads 1 and 5 are excavated along the strike of the ore body, and the mining roadway 2 arranged between the one-step stope and the second-step stope is used Unicom, the bottom-drawing roadway 3 is arranged in the center of the bottom of the stope, and the mine-exiting roadway 2 and the drawing-bottom roadway 3 are connected with the ore loading access road 4 with a spacing of 8-12m.

[0036] (3) The down-the-hole drilling rig rock drilling unit 9 is lowered fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com