One-pump multi-injection profile control device for oil field and profile control method

An oil field and profile control technology, which is applied to the valve device of wellbore/well, earthwork drilling and production of fluids, etc., can solve the problems such as the inability to meet the demands of oilfield profile control workload, etc., to improve profile control efficiency and work Efficiency and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

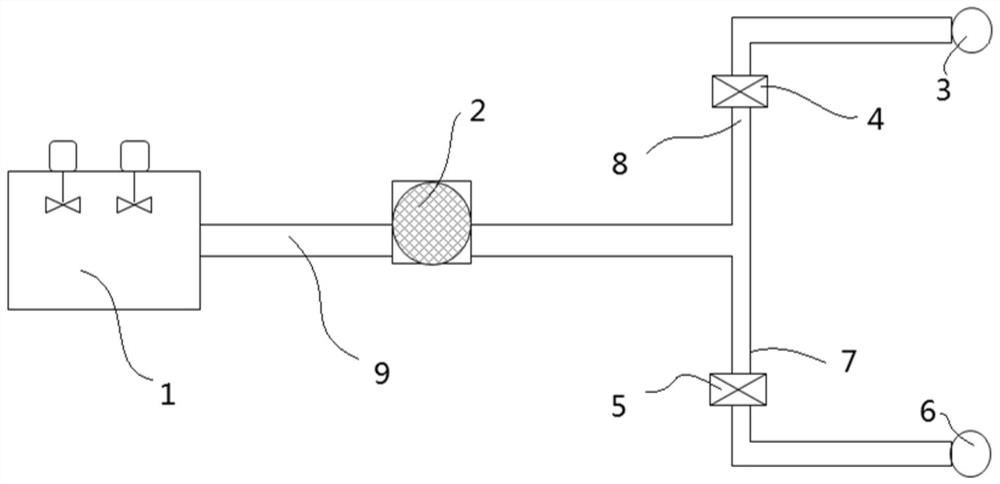

[0033] refer to figure 2 , in order to effectively improve the implementation efficiency of oilfield profile control operations and reduce the implementation cost, the profile control equipment has been improved and upgraded. Through the transformation at the outlet end of the profile control pump, one outlet has been changed into two outlets, and the purpose of separate distribution can be realized simultaneously. The profile control operation of the two water injection wells has greatly improved the work efficiency and reduced the operation cost. Theoretically, the construction cost can be reduced by 50%.

[0034] The end of the original profile control plunger pump has only one outlet, which is converted into two outlets by connecting the three-way device, and a steady flow water distributor is installed on the two outlet pipelines to achieve flow control, and the two outlet pipelines are respectively connected to the two injection ports. On the well, according to the prof...

Embodiment 2

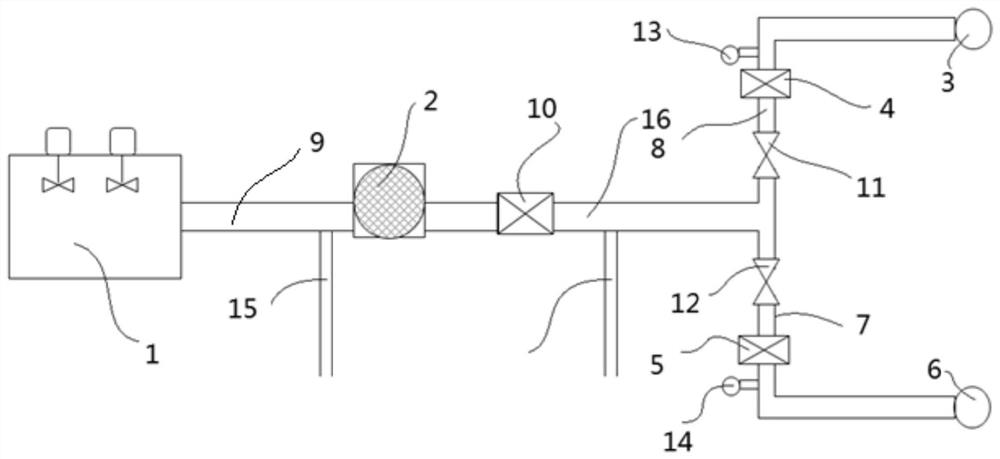

[0043] refer to image 3 , a one-pump multi-injection profile control device, including a liquid distribution tank 1 and a profile control pump 2, the outlet of the liquid distribution tank 1 is connected to the inlet of the profile control pump 2 through a liquid inlet pipeline 9, and the outlet of the profile control pump 2 is connected to the connecting pipeline The inlet of 16 is connected, the outlet of connecting pipeline 16 is connected with the first end of the first outlet pipeline 7 and the first end of the second outlet pipeline 8, the second end of the first outlet pipeline 7 is the first outlet port, and the second outlet The second end of line 8 is the second outlet port. A sampling tube 15 is connected to the liquid inlet line 9 for sampling and testing the liquid flowing out of the liquid dosing tank 1 .

[0044] Among them, a first one-way stop valve 10 is installed on the connecting pipeline 16, and a second one-way stop valve 11, a first steady flow water d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com