An installation structure of an adjustable sealing strip and a leakage gate

A technology for installing structures and sealing strips, used in sealing devices, windows/doors, building components, etc., can solve problems such as high cost, poor wall flatness, and difficulty, and achieve precise and convenient micro-adjustment operations. Gap error, the effect of increasing the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

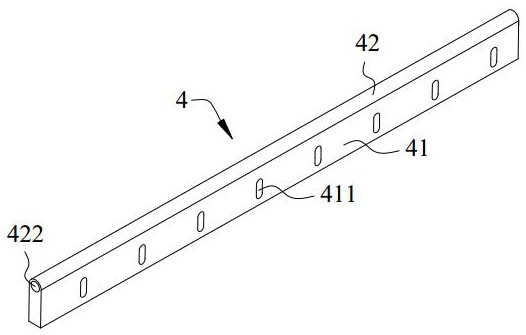

[0050] see figure 1 , the embodiment of the present invention provides an adjustable sealing strip, the sealing strip 4 includes a body extending along the length direction of the sealing strip, and the body includes a mounting part 41 and a sealing part 42 .

[0051] The mounting portion 41 extends along the length direction of the weather strip, and is provided with a plurality of waist holes 411 at intervals along the length direction of the weather strip. The length direction of the waist holes 411 is perpendicular to the length direction of the weather strip, several waist holes 411 are parallel to each other, and all the waist holes 411 pass through the mounting portion 41 of the weather strip 4 .

[0052] A real-time method is that a plurality of waist holes 411 are equally spaced and evenly distributed on the mounting portion 41 of the sealing strip 4 , which can better adjust the installation position of each part of the sealing strip 4 .

[0053] The sealing portion 4...

Embodiment 2

[0056] see figure 2 , Figure 7 to Figure 10 , the embodiment of the present invention provides an adjustable sealing strip installation structure, the installation structure includes a sealing strip 4, a mounting plate 5, a pressing plate 6 and a clamping assembly 7 and the like.

[0057] The sealing strip 4 is the sealing strip described in the first embodiment above.

[0058] The mounting plate 5 is in the shape of a long strip, which is matched with one side of the mounting portion 41 of the sealing strip 4. When the sealing strip 4 is assembled on the mounting plate 5, its sealing portion 42 extends to the outside of the mounting plate 5 to achieve deformation sealing Function.

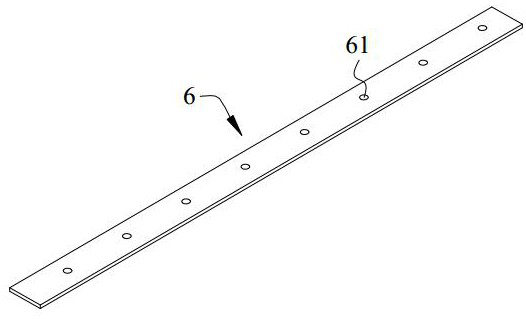

[0059] The pressing strip 6 is in the shape of a long strip, which is matched with the other side of the mounting portion 41 of the sealing strip 4 , and is used for clamping the sealing strip 4 in cooperation with the mounting plate 5 .

[0060] The clamping assembly 7 includes a first screw...

Embodiment 3

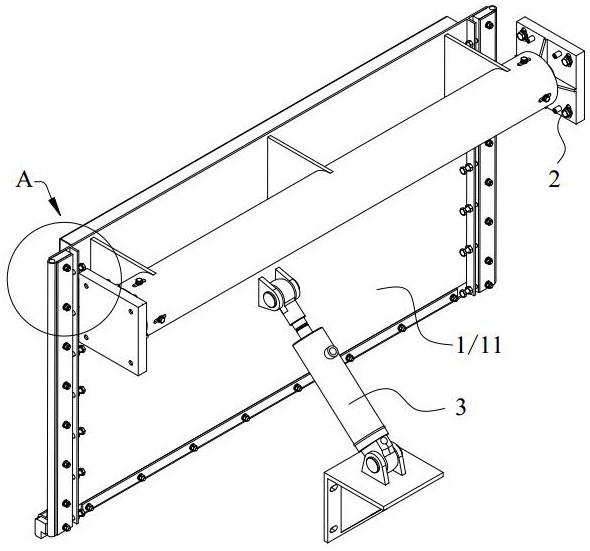

[0068] see Figure 3 to Figure 10 , the embodiment of the present invention provides a leakage gate, which includes a door panel 1 , a support base 2 , a drive assembly 3 and the like.

[0069] The size of the door panel 1 is adapted to the weir mouth for intercepting the water flow. The support base 2 is fixedly installed on the side wall of the weir mouth, and is rotatably connected with the door panel 1 for supporting the door panel 1 . The drive assembly 3 is connected with the door panel 1 and is used to drive the door panel 1 to rotate around the support base 2 to realize the opening or closing of the lower end of the door panel 1 .

[0070] The door panel 1 is provided with a first pressure bearing surface 11 and a second pressure bearing surface 12, and the first pressure bearing surface 11 and the second pressure bearing surface 12 correspond to the upstream and downstream of the water flow at the weir, respectively. The edge of the first pressure-bearing surface 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com