Self-climbing steel structure house and operation method thereof

A steel structure, self-climbing technology, applied in the direction of building structure, construction, etc., can solve the problem of flood influx into the house, affecting the normal use of steel structure houses, etc., to achieve the effect of ensuring simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

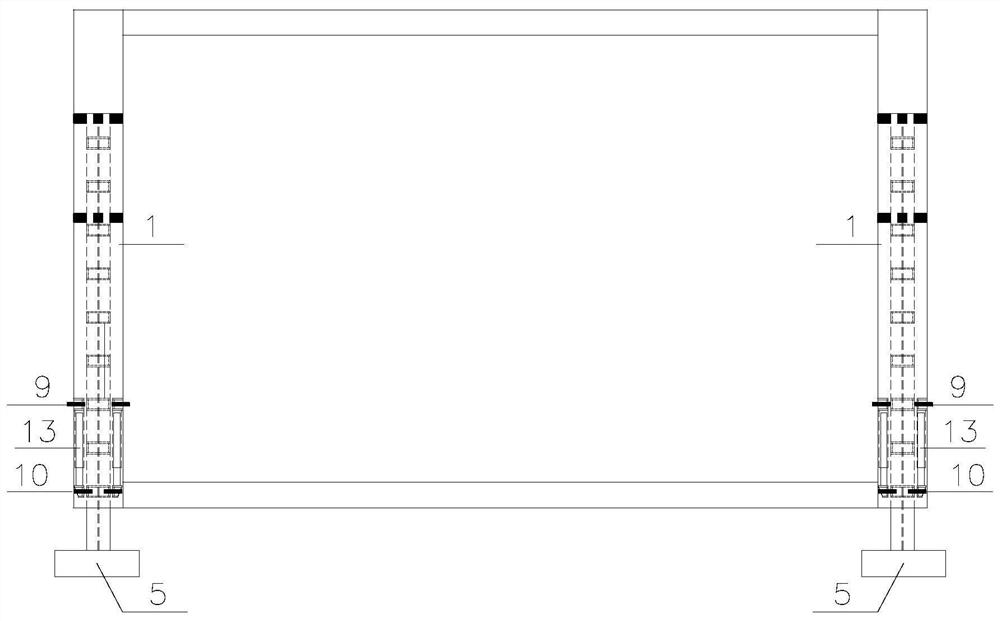

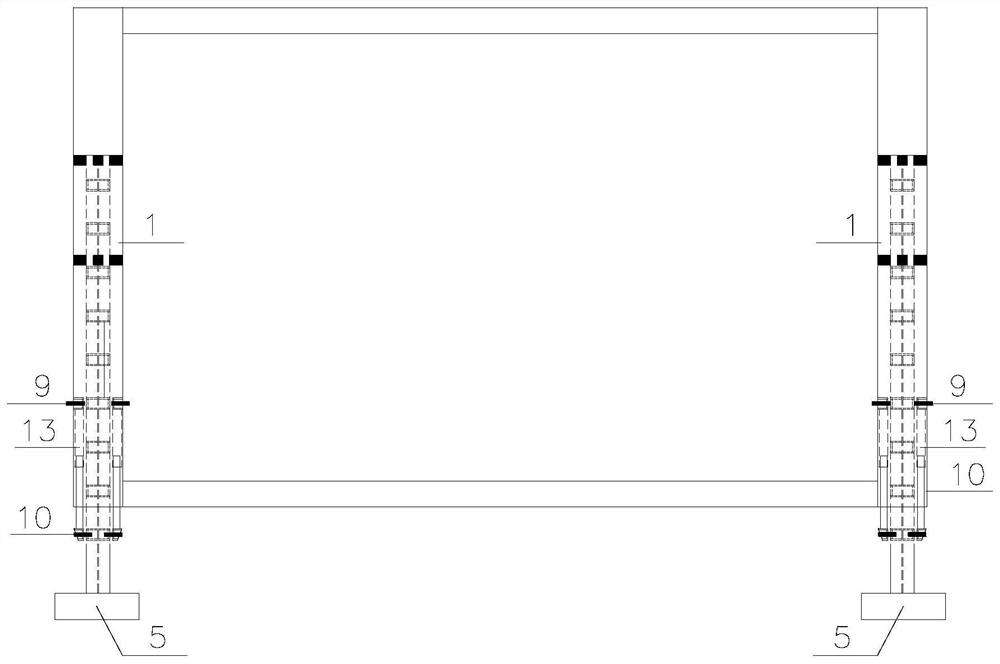

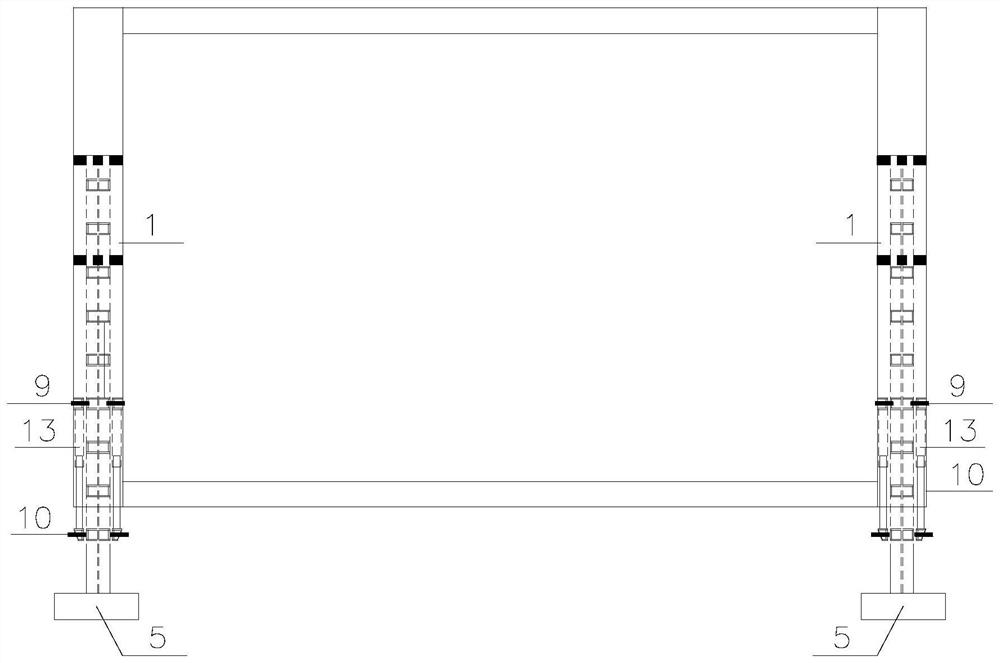

[0038] Such as Figure 1 ~ Figure 4 As shown, a self-climbing steel structure house includes a house body, an outer column 1 is arranged on the side of the house body, a column 2 is installed inside the outer column 1, and a self-jacking oil cylinder 13 is installed between the outer column 1 and the column 2 , the top and bottom of the self-jacking oil cylinder 13 are detachably connected to the column 2 through the first automatic latch 9 and the second automatic latch 10 respectively, and the bottom of the column 2 is provided with a foundation 5 in contact with the ground. In this embodiment, the outer The column 1 is specifically a square steel pipe, and the column 2 is specifically an H-shaped steel pipe.

[0039] Among them, column 2 such as Figure 5 with Image 6 As shown, a plurality of corbels 6 are arranged at equal intervals on the column 2, and the distance between the two corbels 6 on the column 2 is equal to the propulsion stroke of the self-jacking cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com