Sewing and trimming device for clothing manufacturing and using method

A technology for trimming and clothing, applied in the field of sewing and trimming devices for clothing manufacturing, can solve the problems of low cutting efficiency, straightening of the thread, easy to break, etc., and achieve the effects of improving work quality, ensuring stability, and being convenient to take.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

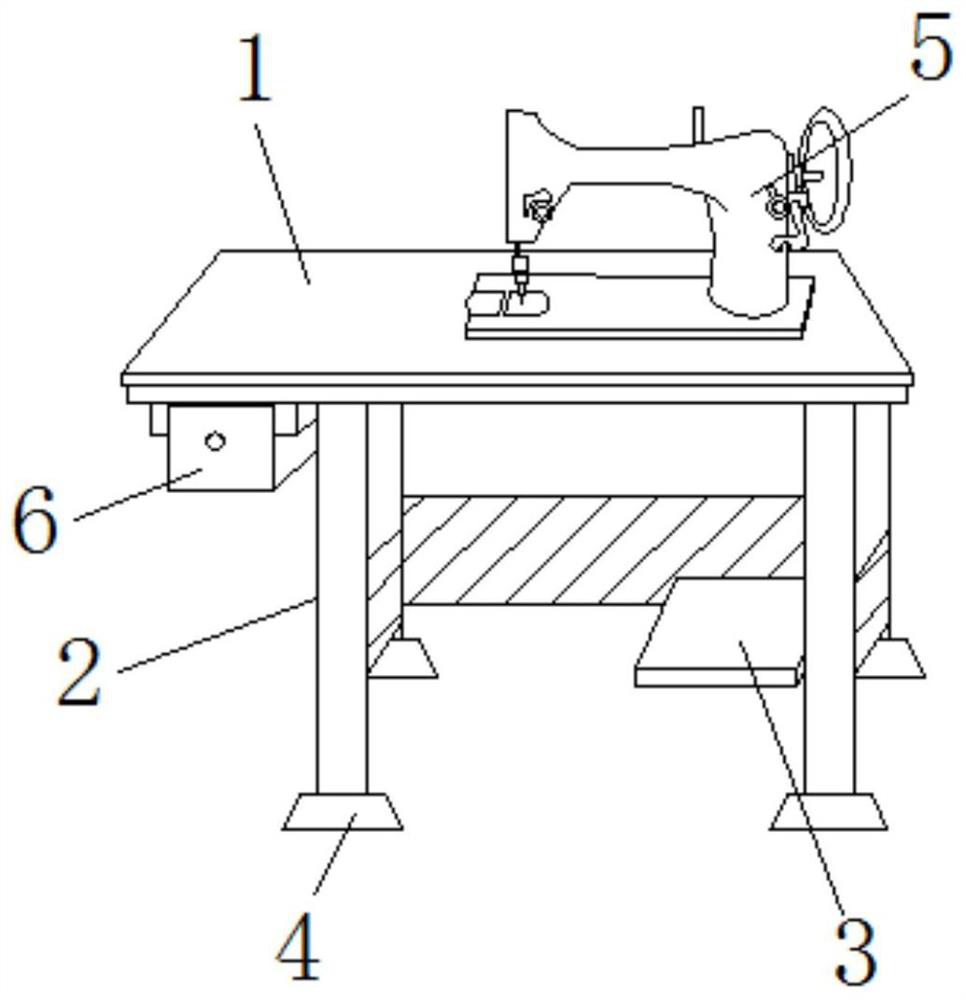

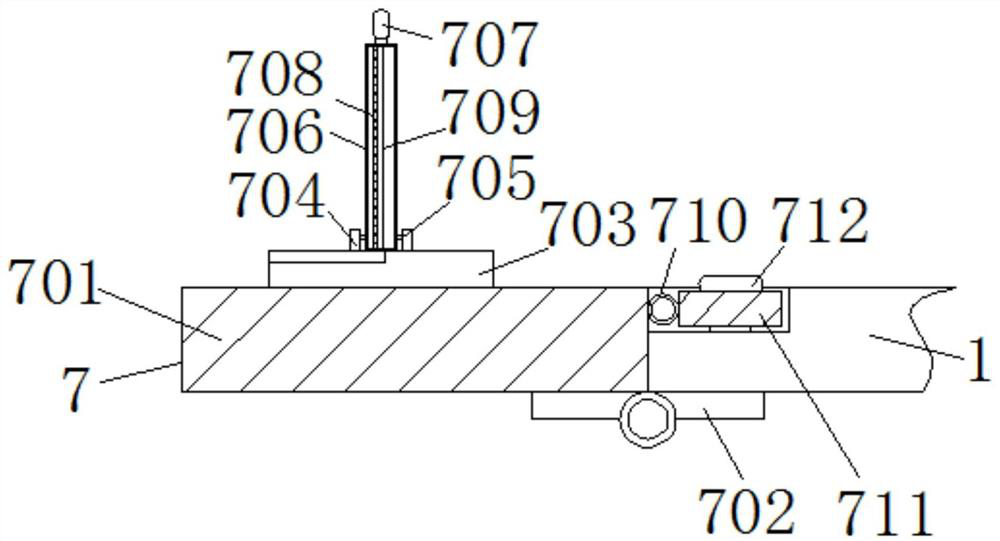

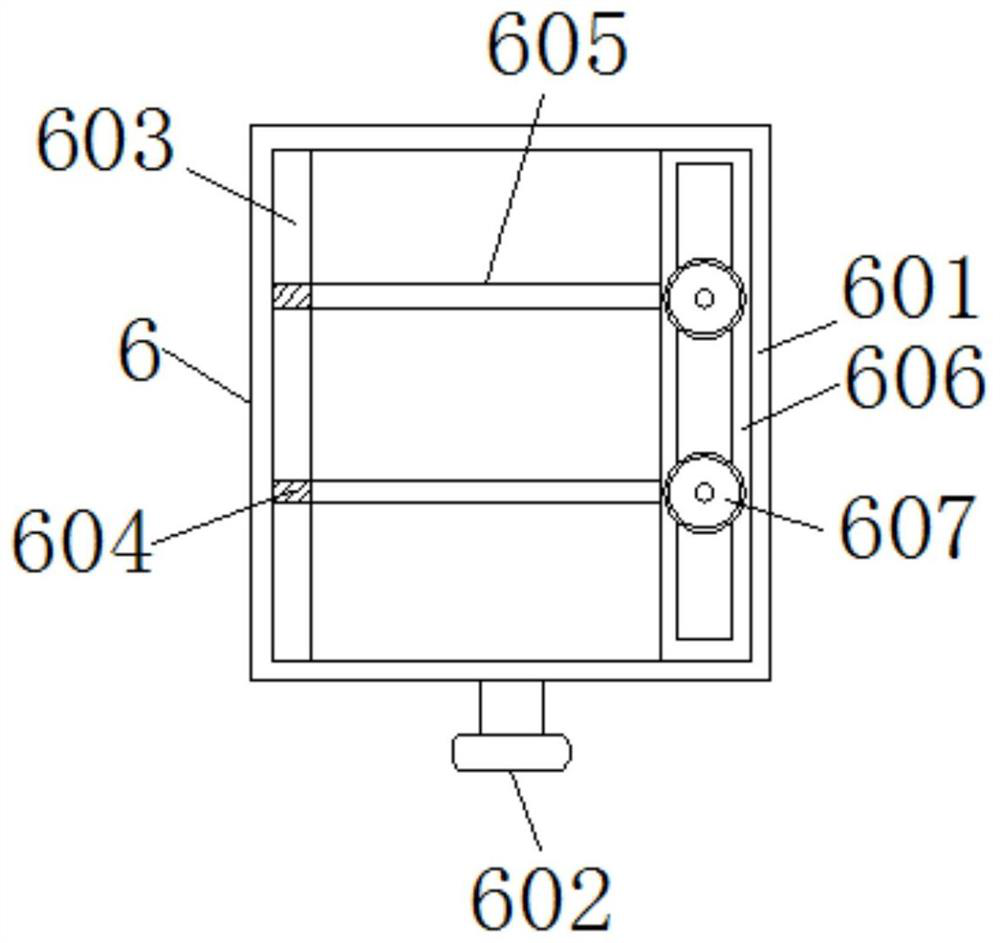

[0045] Refer to Figure 1-6 , A sewing and trimming device for apparel manufacturing, comprising a workbench 1, a support frame 2, a foot pedal 3, a stabilizing mechanism 4, a chassis 401, a threaded rod 402, a first nut 403, a second nut 404, and a sewing device 5. Place storage mechanism 6, place box 601, first handle 602, guide groove 603, guide block 604, partition 605, side plate 606, first hand screw bolt 607, place bag 608, first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com