Chemical liquid agent filling system

A filling system and chemical liquid technology, applied in liquid bottling, liquid processing, packaging, etc., can solve the problems of large contact between fluid and air, poor sealing between the bottle mouth and filling head, and poor sealing, and achieve splash-proof effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the drawings.

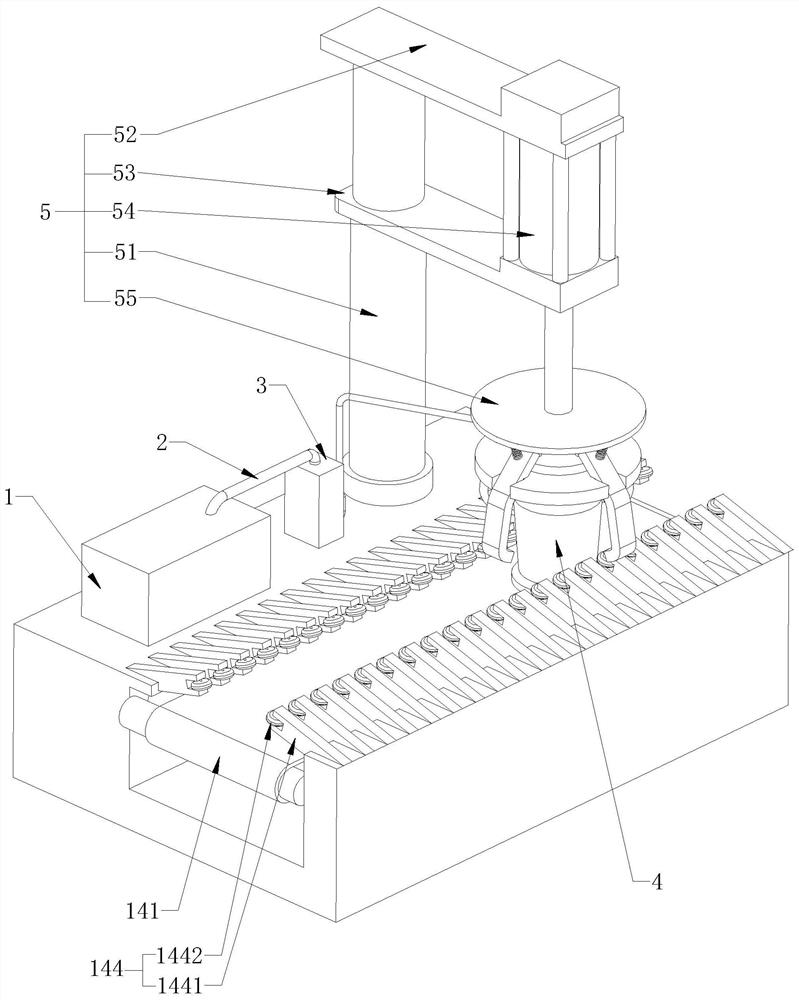

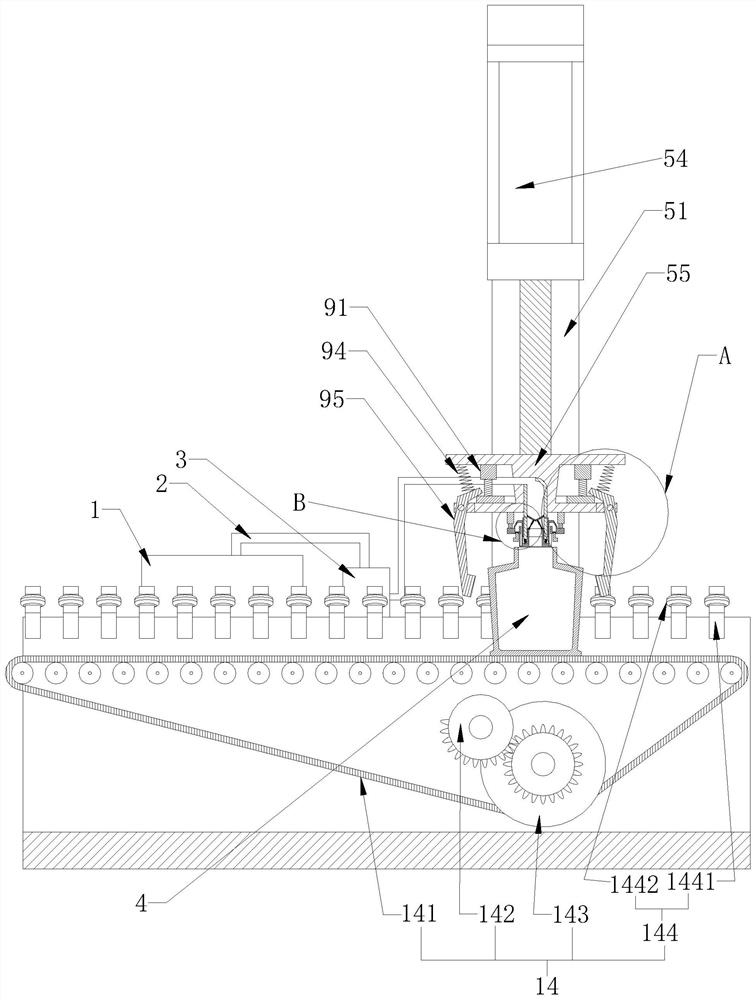

[0034] Refer to figure 1 Shown here is a chemical liquid medicament filling system disclosed in the present invention, including a feeding box 1, a conveying pipe 2, a liquid pump 3, and a liquid bottle 4. The equipment also includes a fixing frame 5, a splash prevention device 6 and an airtight The device 7, the fixed frame 5 is set on the workbench and the splash-proof device 6 and the air-tight device 7 are installed; the splash-proof device 6 prevents the input liquid from splashing, and the air-tight device 7 ensures better air-tightness when liquid is injected and improves the quality .

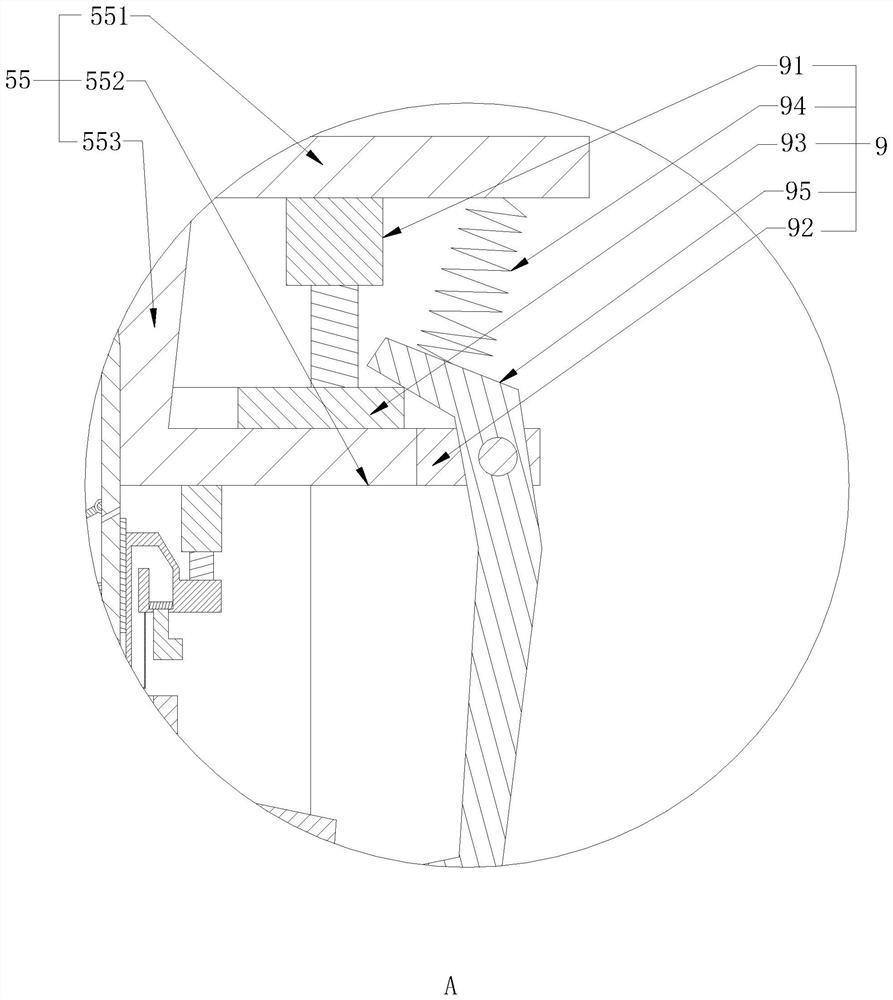

[0035] Continue to refer figure 1 As shown, the fixing frame 5 includes a support column 51, an upper mounting plate 52, a lower mounting plate 53, a hydraulic cylinder 54 and an I-shaped disc 55; in this embodiment, the workbench is set in a dark and dry area in the workshop, and is I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com