Intelligent steel plate cutting and blanking production line and production method thereof

A production line, steel plate technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, only applicable to production lines, not universal, etc., to achieve a small footprint, improve work efficiency, production Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

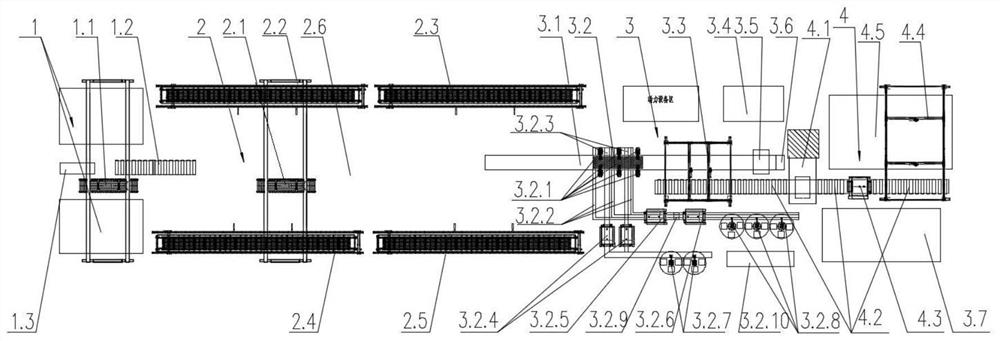

[0033] Such as figure 1 As shown, the steel plate cutting and blanking intelligent production line of this embodiment includes sequentially set up: a steel plate incoming buffer area 1, a steel plate cutting area 2, a parts sorting and waste processing area 3, and a large-piece leveling and sanding area 4.

[0034] The production line of the patent of the present invention can be applied to workshops with different spans. The steel plate incoming material buffer area 1 is set at the forefront of the production line. The steel plate incoming material buffer area 1 is sequentially composed of the first intelligent crane 1.1, the steel plate transport centering mechanism 1.2, The logistics vehicle parking and unloading space is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com