Conic traverse flame tube

A technology of flame tube and tubular body, which is applied in the field of combustion chamber to achieve the effect of eliminating inhalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

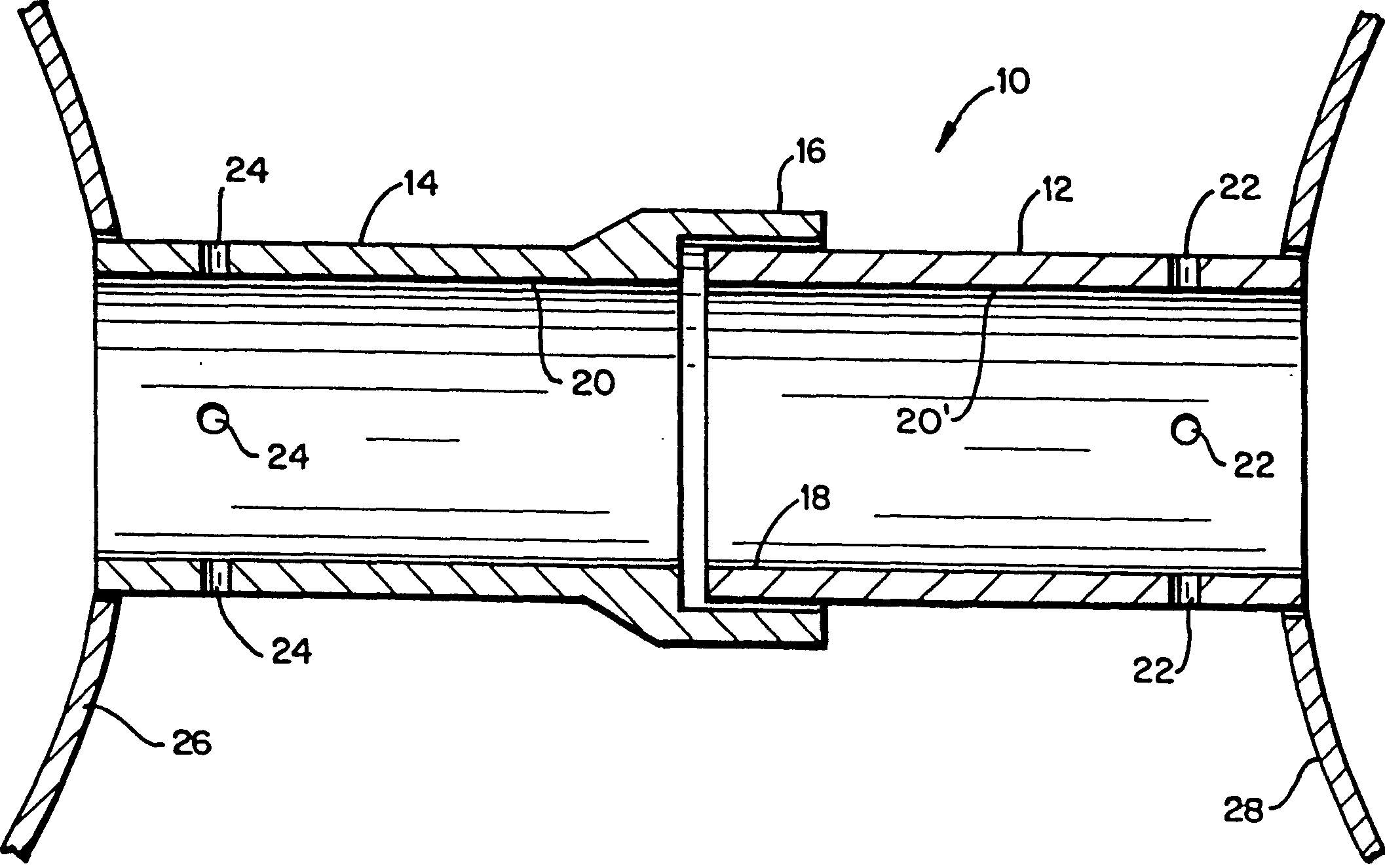

[0018] see first figure 1 A cross-fire tube 10 of conventional construction includes a generally cylindrical insert portion 12 and a generally cylindrical sleeve portion 14 having an enlarged end 16 for telescopic The free end 18 of the insertion portion 12 is received in relation thereto and is held there by any suitable means. The interior of the cross-fire tube is characterized by inner walls 20, 20' having substantially the same diameter. A plurality of air purge holes 22 , 24 are drilled in the region of each insert portion 12 and sleeve portion 14 adjacent a respective combustor liner 26 , 28 , respectively. The problems associated with this conventional cross-fire tube configuration have been described above and need not be repeated here.

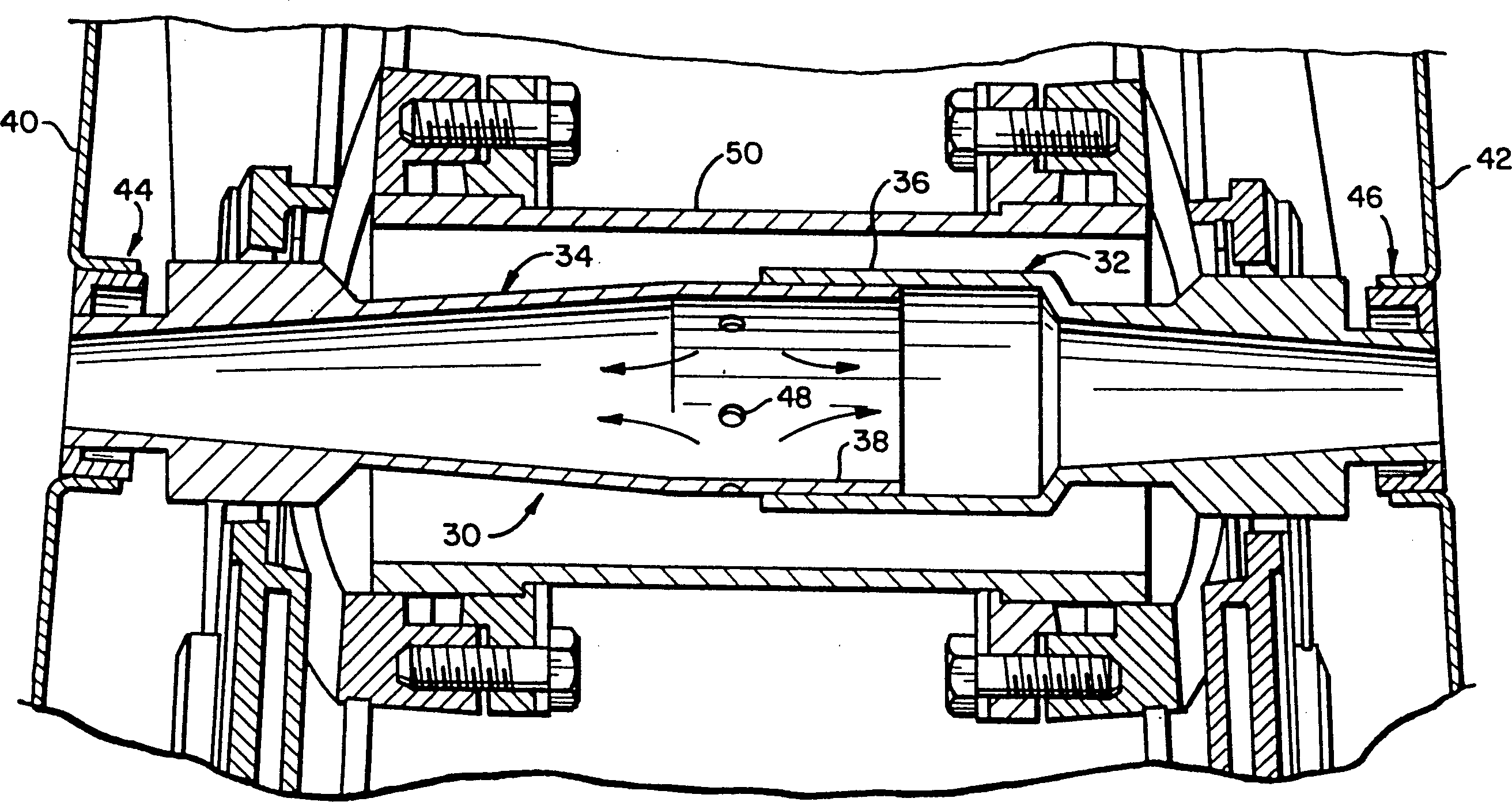

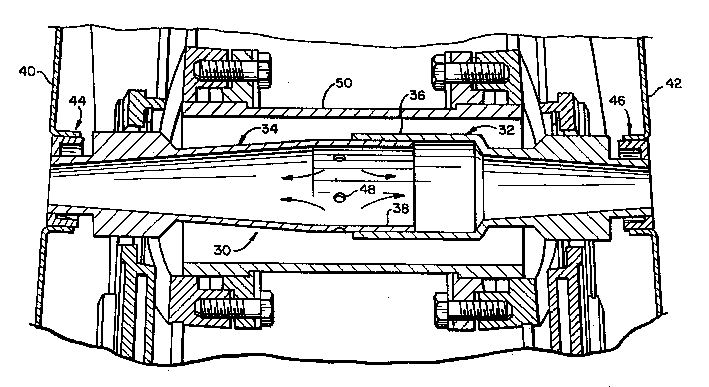

[0019] see now figure 2 A cross-fire tube according to an exemplary embodiment of the present invention includes a tubular body 30 having a sleeve portion 32 and an insert portion 34 . The sleeve portion 32 has an enlarged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com