A method for recycling waste liquid from quantum dot purification

A waste liquid recovery and quantum dot technology, which is applied in chemical instruments and methods, separation methods, liquid separation, etc., can solve the problems of cumbersome and complicated recycling methods and high recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

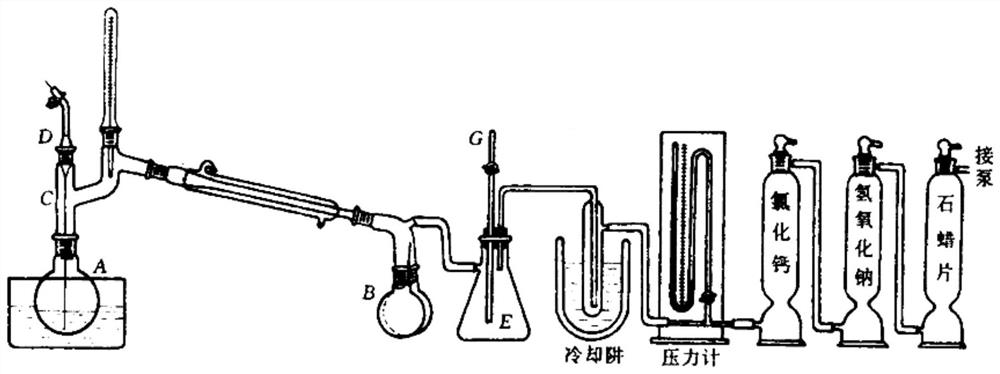

[0028] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

[0029] For the recovery of the waste liquid produced by quantum dot purification, the commonly used recovery methods are to use azeotropic distillation, extractive distillation and membrane separation to extract the alkanes and alcohols in the waste liquid respectively. Alkanes and alcohols are then reconstituted for subsequent purification. This method is more cumbersome and complicated, and will result in higher recycling costs.

[0030] In view of the above problems, the inventors of the present application propose the following embodiments to solve the above problems after research and exploration.

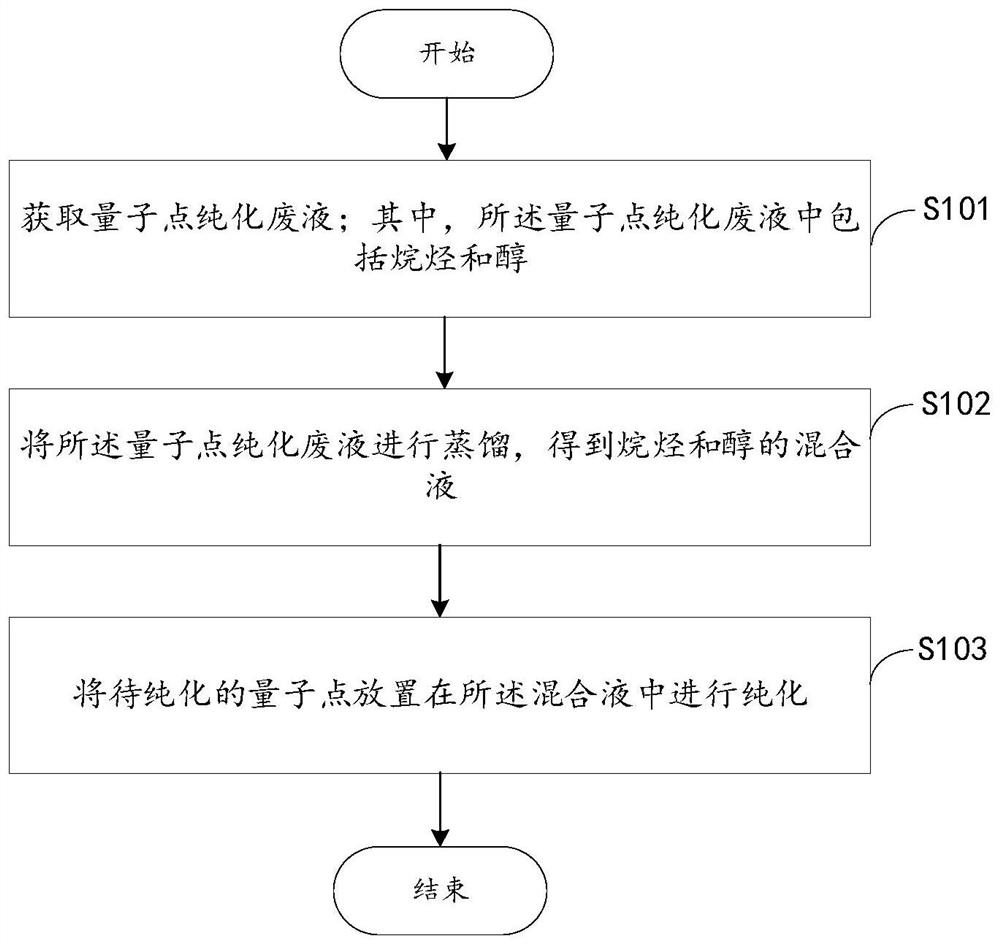

[0031] see figure 1 , the embodiment of the present application provides a method for recycling quantum dot purification waste liquid, the method includes: step S101-step S103.

[0032] Step S101...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com