A motor stator performance testing machine

A motor stator and testing machine technology, which is applied in the mechanical field, can solve the problems of lower production efficiency and operator danger, and achieve the effects of easy maintenance, small footprint and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be further described in detail below.

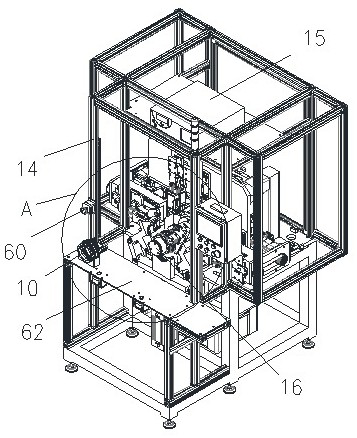

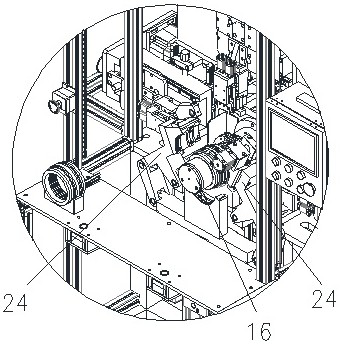

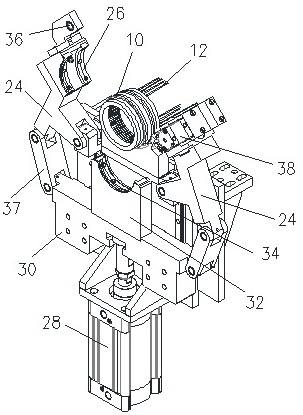

[0021] Such as Figure 1 to Figure 5 As shown, a motor stator performance testing machine of the present invention is used to test the electrical performance of a cylindrical stator, and the stator 10 includes several wires 12 . The present invention includes a frame 14, the side of the frame 14 facing the operator is its front, and a tester 15 for connecting the stator wiring 12 to test the performance of the stator is arranged in the frame 14, and the tester 15 is used for testing the stator. The equipment used for pressure and other testing is a mature product on the market. A cylindrical support column 16 is arranged horizontally towards the front on the frame 14. The support column 16 is made of insulating material. Line device 18. Each thread breaking device 18 all comprises several thread breaking knives 20 made of metal and a driving device 22, and all thread breaking k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com