A land test device and method for a submersible hoisting system

A land test and submersible technology, applied in the testing, measuring devices, instruments and other directions of machine/structural components, can solve problems such as problems, debugging, large test workload, and difficulty in land tests, and achieve a simple structure. Safety and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following structural description drawings further describe the specific technical solutions of the present invention.

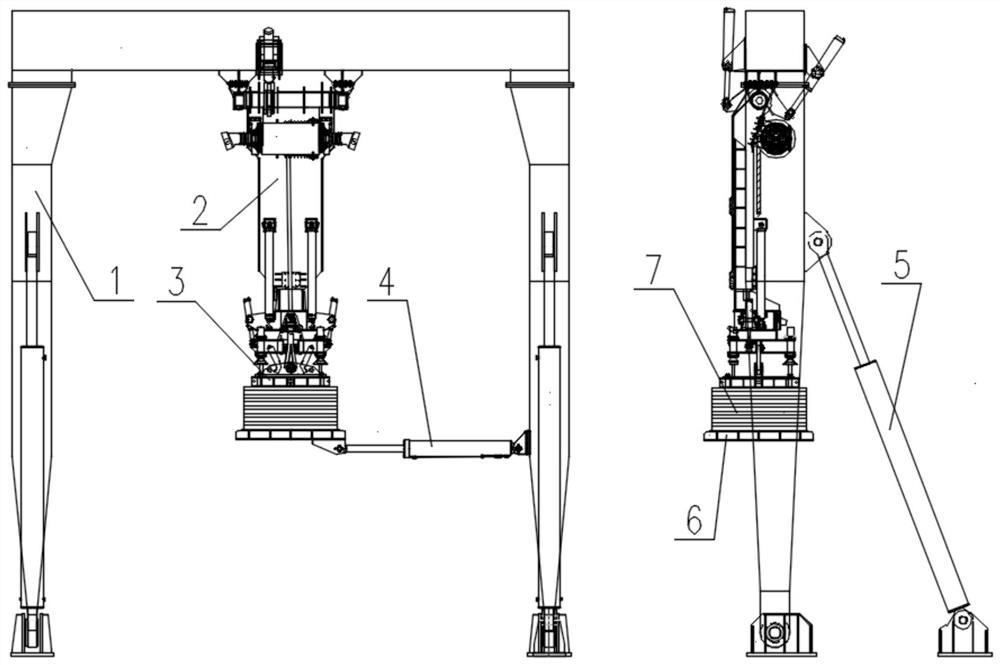

[0047] as attached figure 1 As shown in the figure, a land test device for a submersible hoisting system of the present invention includes a tooling gantry 1, a guiding tooling 3, a roll drive mechanism 4, a pitch drive mechanism 5, a weight tray 6 and a weight Code 7.

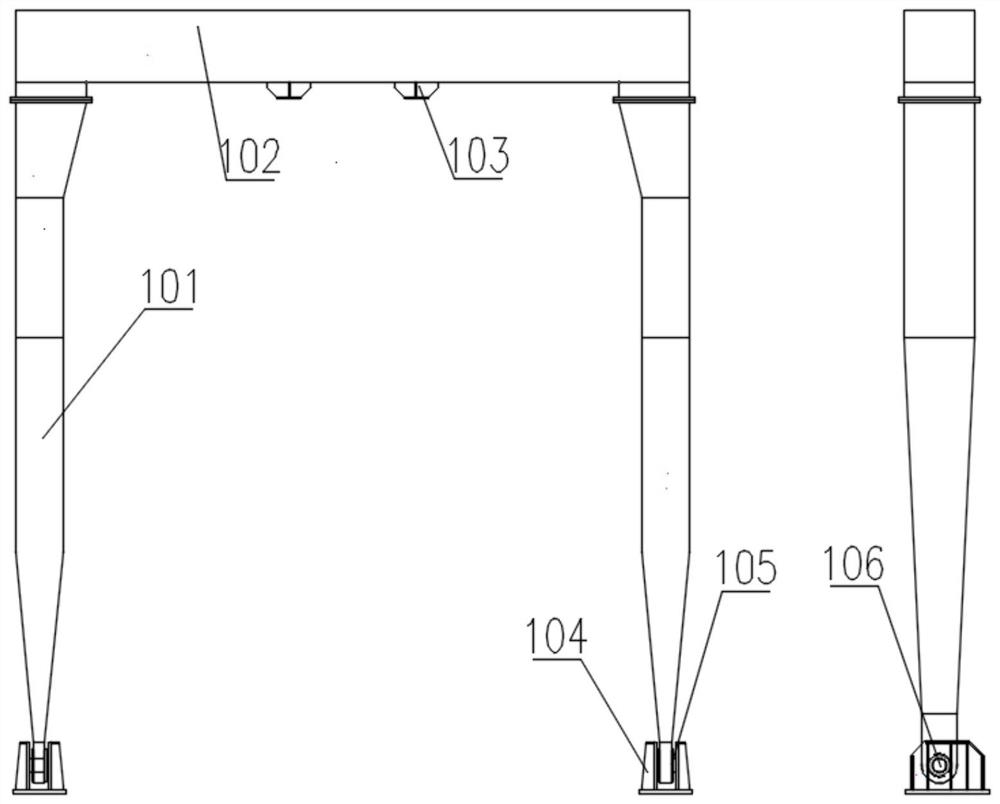

[0048] as attached figure 2 As shown, the tooling gantry 1 is mainly composed of outriggers 101 , beams 102 , a mounting seat 103 for a hoisting system, a base 104 , a gantry bearing 105 , and a gantry pin shaft 106 . The beam 102 and the outriggers 101 are box-shaped structures with reinforcing ring bars and longitudinal bars inside, and the beams 102 and the outriggers 101 are connected by high-strength bolts. The mounting seat 103 of the hanging system is welded on the bottom of the beam 102, and there are two left and right. The bottom bottom plate of the base 104 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com