Onshore test device and method for submersible lifting system

A land test and submersible technology, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as problems, debugging, heavy test workload, and difficult land test, and reduce costs , Simple structure and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific technical solutions of the present invention are further described in the accompanying drawings of the structural description below.

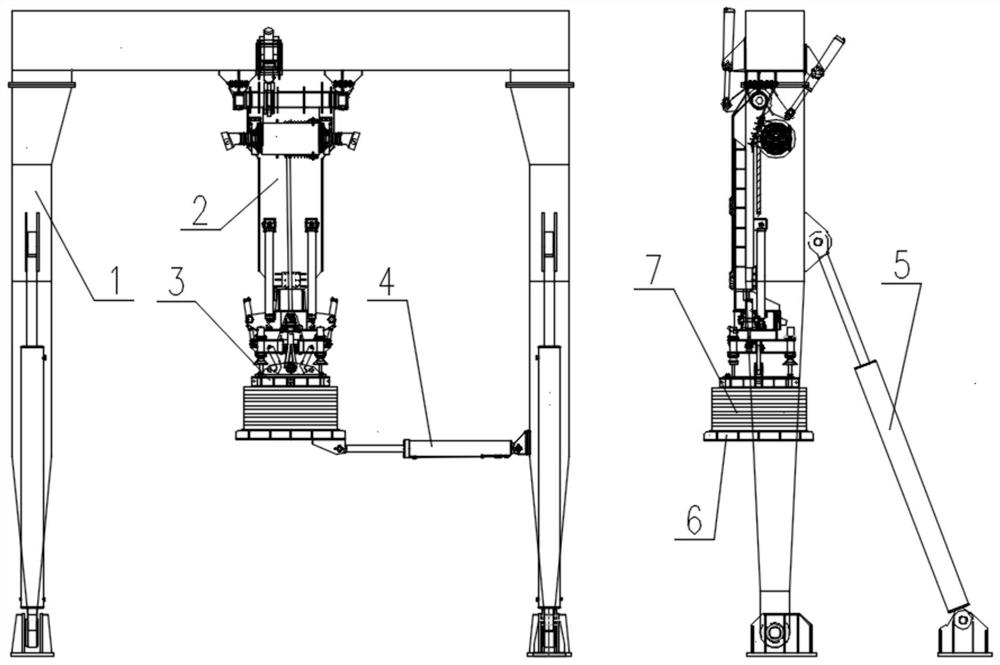

[0047] as attached figure 1 As shown, a land test device for a submersible lifting system of the present invention includes a tooling gantry 1, a guide tooling 3, a pan driving mechanism 4, a pitch driving mechanism 5, a weight tray 6 and a weight Code 7.

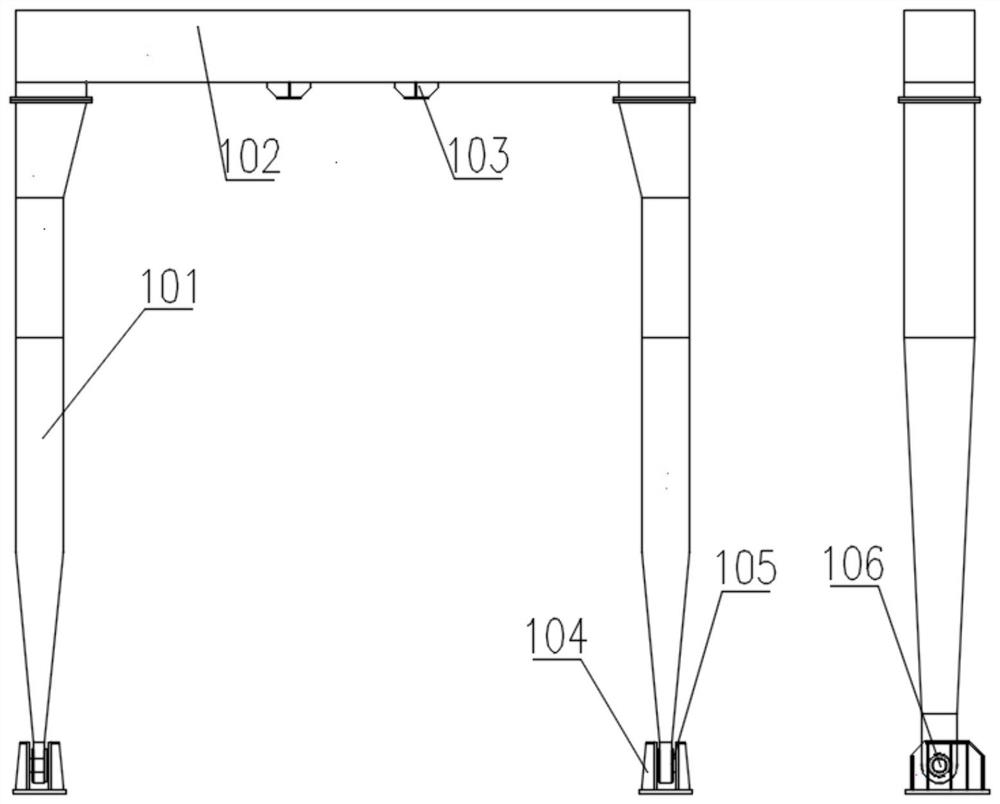

[0048] as attached figure 2 As shown, the tooling gantry 1 is mainly composed of legs 101 , beams 102 , mounting bases 103 for lifting systems, bases 104 , gantry bearings 105 , and gantry pins 106 . The crossbeam 102 and the outrigger 101 are box-shaped structures with reinforcing ring reinforcement and longitudinal reinforcement inside, and the crossbeam 102 and the outrigger 101 are connected by high-strength bolts. The hanging system mounting seat 103 is welded on the bottom of the beam 102, and there are two left and right. A ring of bolts on the lower bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com