Hollow microsphere three-dimensional matrix layer shutter for heat insulation, sound insulation, self-cleaning, sterilization and air cleaning

A three-dimensional matrix, heat and sound insulation technology, applied to soundproof doors/windows, building components, buildings, etc., can solve problems such as lack of beads, cumbersome coatings, and affecting sightlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

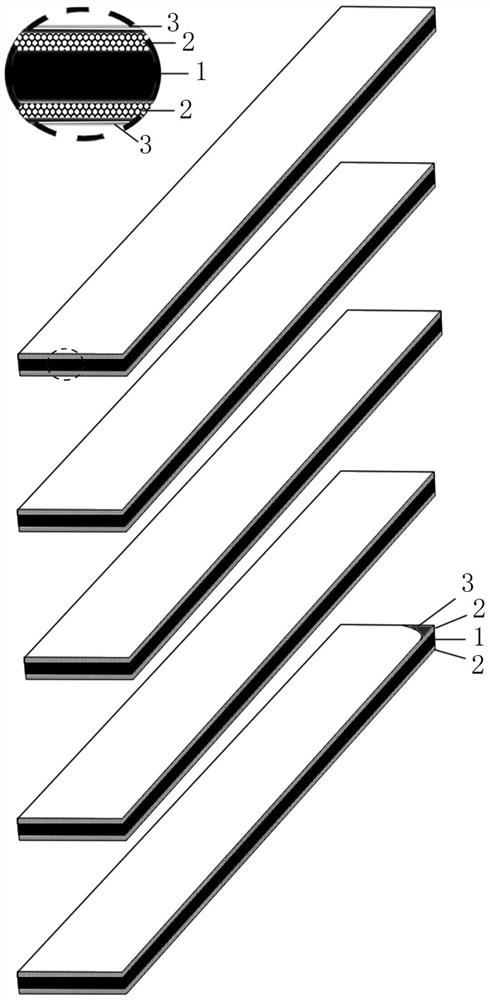

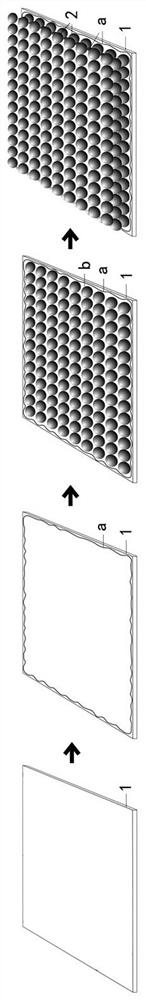

[0015] exist figure 1Among them, the upper and lower surfaces of the louver substrate 1 with a thickness of 0.18 mm are each coated with a 0.2 mm three-dimensional matrix layer of hollow microbeads 2, and the surface layer of the three-dimensional matrix layer of hollow microbeads A titanium dioxide anti-radiation film 3 is coated, and the titanium dioxide anti-radiation film 3 is nano-scale ruby-type titanium dioxide. In summer, the three-dimensional matrix layer of hollow microbeads with heat insulation, sound insulation, self-cleaning and sterilization to clean the air can reflect the heat radiation of the sun with a reflectance of more than 83%, and at the same time absorb most of the heat with a hemispherical emissivity of more than 87%. The three-dimensional matrix layer of hollow microbeads in the louvers further blocks the conduction of the heat flow that has entered the particle, effectively reducing the temperature of the outer surface of the building, thereby reduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com